MAINTENANCE 23

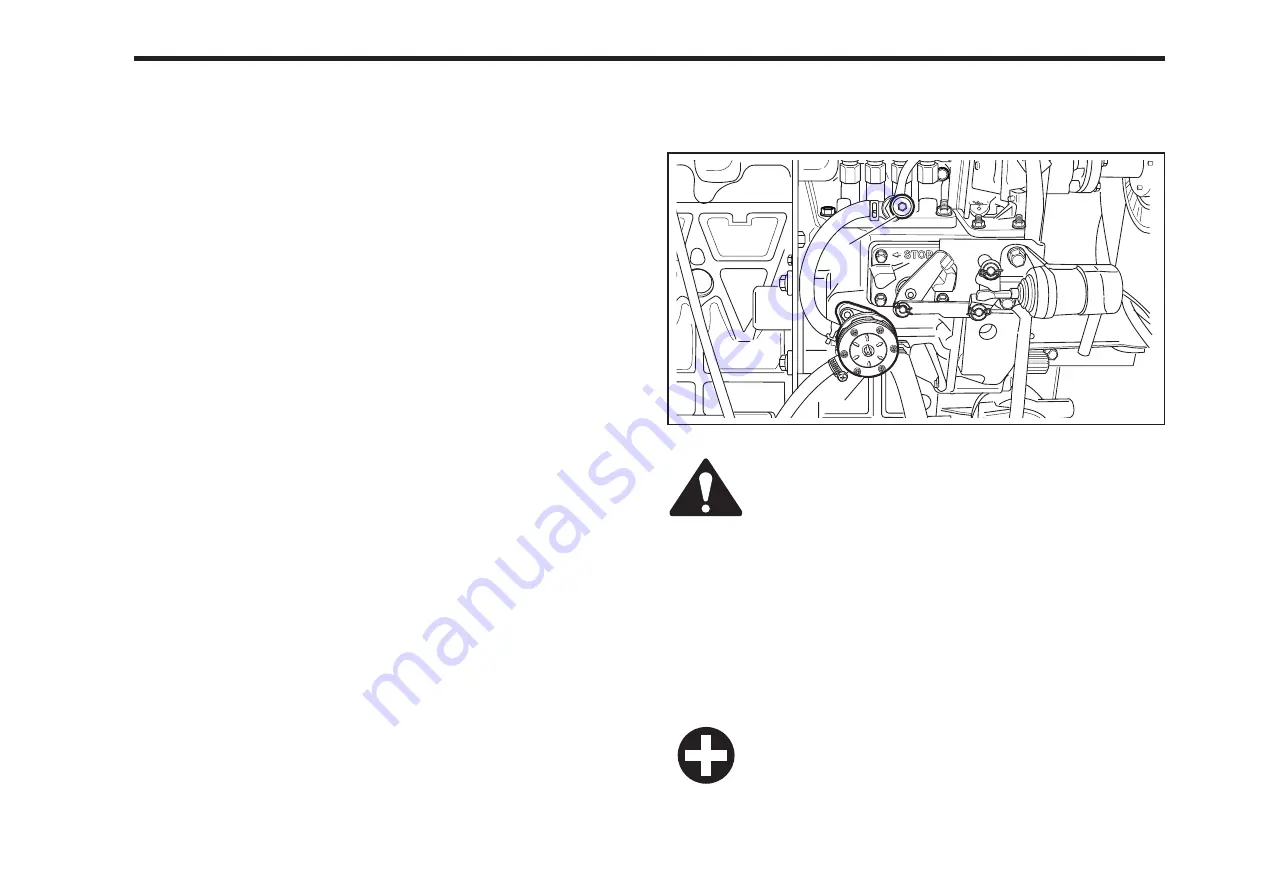

4. When the engine starts or when air is expelled from the

injection pump, close the air vent knob by turning it

clockwise.

5. If the engine still does not start, loosen the fuel line con-

nection at the injection nozzle. Crank the engine for 5 sec-

onds and retighten connection. If the engine still will not

start, repeat this procedure for the remaining injection

nozzles in sequence.

6. Clean up any fuel spills immediately. Start the engine and

check for leaks.

7. If the engine fails to start after bleeding the fuel system,

contact your dealer.

(1) Air vent cock

(2) Fuel pump

CHECKING THE FUEL LINES

Check the fuel lines after every 50 hours of operation.

1. Check and tighten all hose clamps.

2. Check and replace rubber fuel lines and clamps as needed.

Replace hoses and clamps every 2 years regardless of

engine usage.

3. Bleed air from the fuel system after service.

1

2

379O501A

CAUTION

To avoid serious injury, always stop the en-

gine and allow it to cool before servicing the

fuel system. Repair fuel leaks promptly to avoid

fire or explosion.

IMPORTANT

Plug ends of open fuel lines during service to

prevent dirt and other contaminants from en-

tering and damaging the fuel system.

Summary of Contents for ?A165

Page 4: ......

Page 5: ...1 SAFETY INSTRUCTIONS...

Page 9: ...2 NAMES OF PARTS...

Page 16: ......

Page 17: ...4 BREAK IN AND CHECKS DAILY CHECKS 18 BREAK IN 18 PERIODIC CHECKS 19...

Page 20: ......

Page 35: ...6 TROUBLESHOOTING...

Page 41: ...7 WIRING DIAGRAMS...

Page 42: ...42 DIESEL ENGINE 379O701A 3C093 SERIES...

Page 43: ...WIRING DIAGRAMS 43 379O702A TD1300 TD1400 TD1700 3A139 3A165 4A200T 4A220 4A220T...

Page 44: ......

Page 45: ...8 SPECIFICATIONS...

Page 46: ......

Page 49: ...9 INDEX...