8

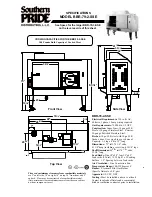

2. To install the bracket, place it against the wall in the mounting

location. Using a drill with a 1/8” diameter drill bit, drill four

(4) 1 5/8” deep pilot holes perpendicular to the screw seating

surfaces shown below. Attach the bracket to the wall as

shown with the four (4) included #12 x 1 3/4 screws.

Installing the Anti-Tip Bracket on the Wall

1. Determine the suitability of wall mounting the anti-tip bracket.

To use the wall mount option, the range front panel (excluding

the bull nose) must not be more than 27” (68.6 cm) from the

wall and the bracket screws must be able to thread into the

base plate inside the wall behind. The notches on the sides

of the bracket indicated the minimum required height of the

base plate inside the wall and that any floor covering is not

too thick for proper screw thread engagement.

To determine if the base plate is high enough:

◊

Determine the location of the range center line and front

panel when the range is in its final position based on the

product dimensions on page 5 and the actual cabinet/

cutout dimensions used for the installation.

◊

Determine and mark the required position of the anti-tip

bracket, based on the diagram above. Push the bracket

up against the wall in the mounting location.

◊

Using a pencil, make a dot next to the notches on both

sides of the bracket. Determine if the base plate is as

high at the notches by drilling test holes into the wall at

both dots with a 1/16” drill bit. Drill just deep enough to

see if the bit contacts the base plate. If the bit contacts

the base plate the location will support wall installation of

the anti-tip bracket. If you do not contact the base plate,

the wall mounting method may not be used and the floor

mounting method must be suitable, or the wall must be

modified so that the base plate is above the notches.

Installation Instructions

CL

CL

Bracket

center line

Range front

panel*

#12 x 1 3/4”

screw, 4 places

This hole lines up with

bracket center line

Back wall

Range

center line

Wall

Anti-tip

bracket

Base

plate

Drywall

Notch

Top View - Location of Wall Mounted Anti-Tip

Bracket

C

ANTI-TIP BRACKET PLACEMENT

Dimension

RNRP36G

RNRP48G

C

11 7/8” (30.2 cm)

2 1/2” (6.4 cm)

* Excludes bull nose (see page 4)