3

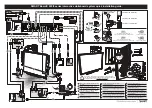

If your screen was shipped with the motor and roller already installed proceed to step 7.

1. Remove the access door. First, remove the 2 bolts from each

end with a 9/16" open wrench or socket driver. Next, use a

5/32" hex key to remove the two screws in the center of the

access door. This will allow the door to drop open on the hinges

(Figure 1).

2. Carefully unpack screen and roller assembly. Leave packing

paper on the roller.

3. Remove the square peg bracket from the motor end of the

roller assembly (Figure 2).

4. Remove the safety clip from the motor attachement bracket

located in the motor end of the screen housing.

5. Use a 1/2" open wrench or socket driver to loosen the four bolts

that secure pin end mounting bracket into housing. Lift pin end

of roller into position and slide the bracket into the roller pin.

Tighten all four bolts. Slide the pin end bracket towards the end

of the case (Figure 3).

6. Place the roller assembly into the case with the motor on the

left side. The limit switches should be facing down. Line up the

head of the motor with the motor attachment bracket.

7. Complete electrical hook-up by snapping motor 1/3 wire

connectors into case connectors (Figure 2).

8. Return to motor end and insert safety clip over casting bracket

to secure motor end.

9. Carefully remove tape strips securing picture surface around

roller. Slat should move freely. (Only if the roller assembly is pre

installed.)

Caution! Do not Cut tape on fabriC with a knife

or any sharp tool. remoVe by hanD.

10. Test installation by running screen up and down a few times.

Be prepared to stop screen should any objects obstruct the

movement of the screen. To prevent damage to the motor, the

standard duty cycle is 1 minute on and 3 minutes off.

11. Re-install the access door. Procedure is the reverse of step 1

listed above.

Tools required for screen and roller assembly:

sCreeN ANd roller AsseMBlY iNsTAllATioN

Bolts

Bolts

Figure 3

Figure 1

Figure 2

9/16“ Open Wrench

or Socket Driver

1/2“ Open Wrench

or Socket Driver

5/32“ Hex Key

Bolts

Access Door

Door Support Screws

Screen Motor

LVC Control Box

Screen Motor

Limit Switches

Summary of Contents for Large advantage electrol

Page 1: ...Instruction Book for Large AdvantaGE ElectroL ...

Page 9: ...9 ...

Page 10: ...10 ...

Page 11: ...11 ...