TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

17

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

6. LOADING THE MEDIA.

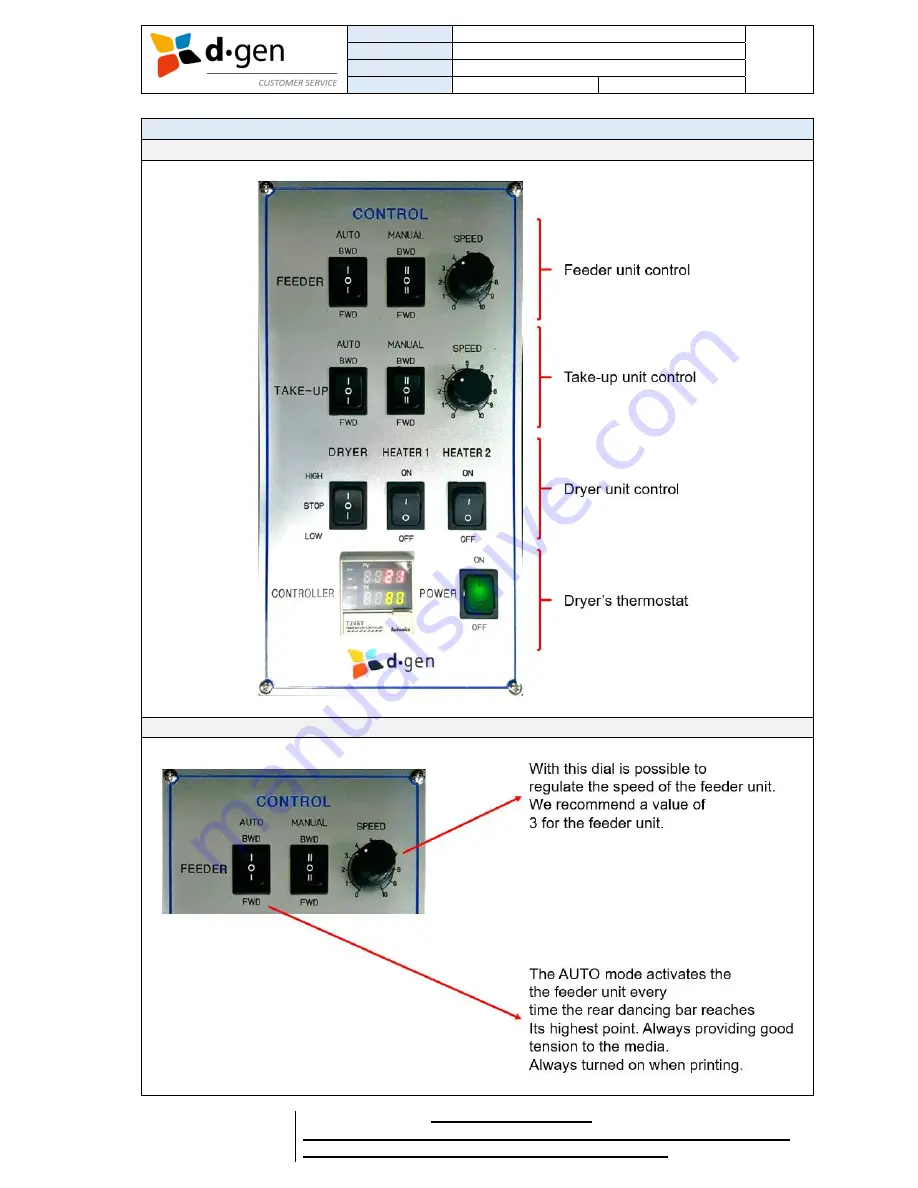

Introducing the printer’s base control panel.

Feeder unit control panel.

Summary of Contents for Papyrus G5/H4

Page 1: ...OPERATOR MANUAL ...