Curtis 1230 Manual,

Rev. C

35

3 — PROGRAMMABLE PARAMETERS:

Motor Control Parameters

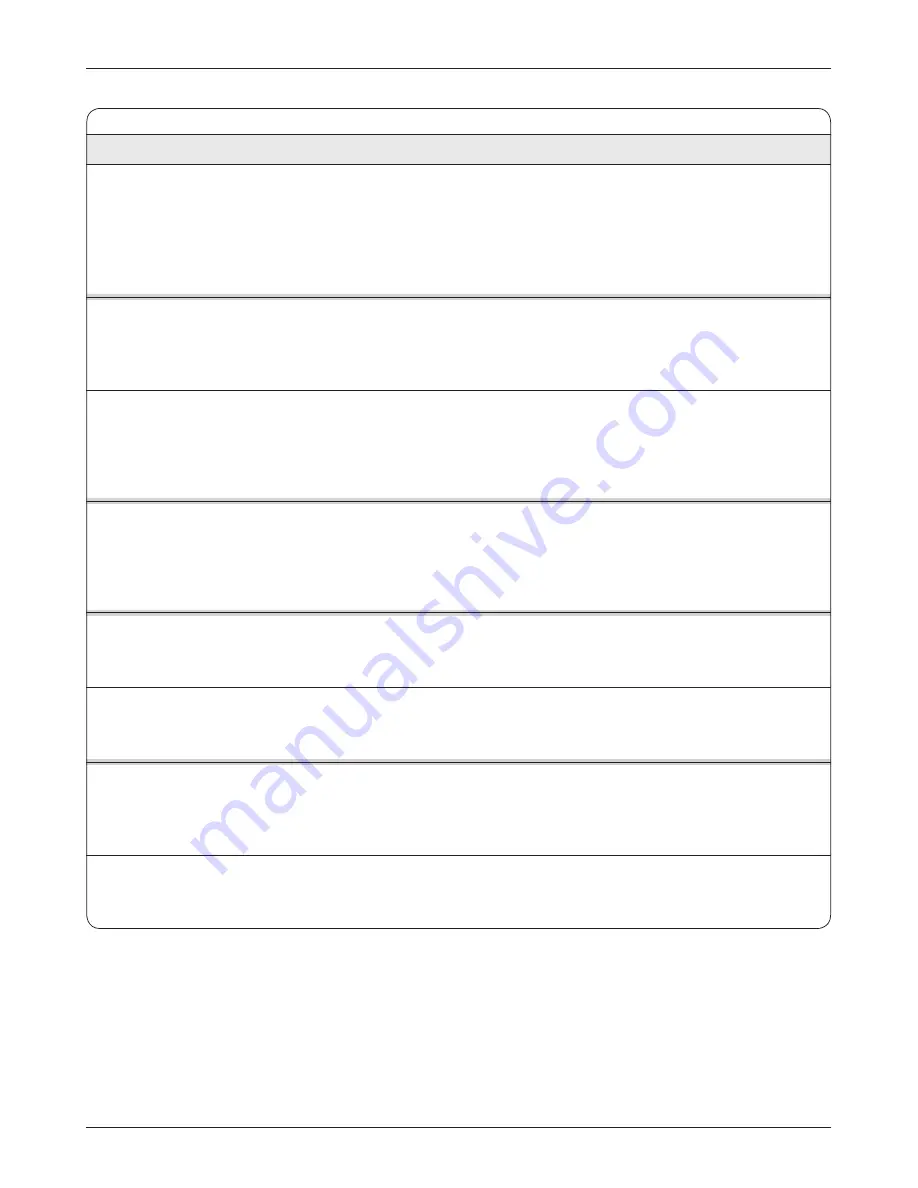

MOTOR MENU

ALLOWABLE

PARAMETER

RANGE

DESCRIPTION

Min Motor Voltage

0.0–6.0 V

Defines the starting point of the V/f profile. This voltage is applied to the

motor at 0 RPM if no (or very low) torque is demanded.

Increasing this parameter can improve low speed behavior, because

the motor will have flux even at zero throttle request. However, if the

parameter is set too high, the motor idle current will be too high, reducing

efficiency and increasing the motor temperature.

Nominal Motor Voltage

7–30 V

This parameter should initially be set according to motor nameplate data.

The nominal motor voltage parameter and the nominal motor frequen-

cy parameter work as a pair to define the slope of the V/f profile.

Note: If set too high, excessive current can damage the motor.

Nominal Motor Frequency

20–400 Hz

This parameter should initially be set according to motor nameplate data.

The nominal motor voltage parameter and the nominal motor frequen-

cy parameter work as a pair to define the slope of the V/f profile.

Increasing the nominal motor frequency makes the V/f profile less

steep and reduces the no-load motor current.

Max Motor Speed

1000–10000 RPM

Defines the maximum motor RPM at full throttle and a 100% setting of

the M1/M2 maximum speed parameter. This parameter can be used to

achieve identical fleet top speed and to limit vehicle and motor speed to

the safe operating area even when running downhill.

Note: If set too high, the bearings and gearbox can be damaged.

Number of Motor Poles

2–8

This parameter must be set according to motor nameplate data. It is used

in calculating the motor output frequency based on the measured encoder

input frequency.

Encoder Pulses/Rev

32–128

This parameter must be set according to motor nameplate data. It is used

in calculating the motor output frequency based on the measured encoder

input frequency.

Swap Encoder Direction

OFF

/

ON

If the speed encoder A and B signals are wired backwards, this parameter

can be used to change the sign of the measured motor speed. It has the

same effect as physically swapping the A and B wires on the encoder

inputs (J2 Pins 2 and 4).

Failsafe Delay

2–20 sec.

If the motor is turning faster than desired, or in the opposite direction, the

controller will shut down the motor and engage the electromagnetic brake

after the programmed failsafe delay.

Summary of Contents for MultiMode 1230

Page 2: ......