Hurricane ES Owner’s Manual

12

4.0

Principles of Operation-

H

H

u

u

r

r

r

r

i

i

c

c

a

a

n

n

e

e

E

E

S

S

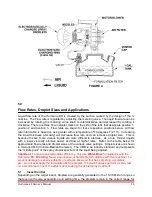

This machine consists of a motor/blower assembly, high voltage power supply, charging

ring and electrode, blower housing, a nozzle, formulation tank and metering valve. The

blower is a two-stage centrifugal compressor driven by a universal motor operating at a

speed of 20,000 rpm. The blower moves a large amount of air through the nozzle

system. The nozzle has six (6) stationary fins, which direct the air to create a swirling

effect of the air mass as it leaves the nozzle. In the center of this exiting swirling air, a

liquid supply spout tube injects formulation. The liquid is delivered to the nozzle by a

negative pressure at the nozzle caused by the exiting air mass. The flow rate is

controlled by a one turn precision metering valve located at the formulation tank.

Generally, the sizes of the output droplets increase with increasing flow rates and with

increasing viscosity of the liquid being dispensed.

After the nozzles shear the formulation into billions of droplets, the droplets are

dispersed into the atmosphere. As the droplets exit the nozzles they pass through an

“electrostatic ion field”. This field is created using the combination of a high voltage

power supply, an emitting electrode and charging ring (Collector). The result is billions

of electrostatically charged droplets that gravitate to neutral objects to form a uniform

coverage. The various components are identified in the fluid systems and major

components diagrams.

Summary of Contents for Aire-Mate Hurricane ES 3001-5

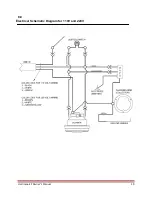

Page 19: ...Hurricane ES Owner s Manual 19 8 0 Electrical Schematic Diagram for 110V and 220V ...

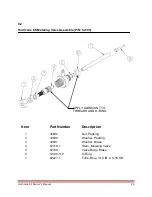

Page 20: ...Hurricane ES Owner s Manual 20 9 0 Hurricane ES Exploded Parts Diagram ...

Page 21: ...Hurricane ES Owner s Manual 21 9 1 Hurricane ES Exploded Parts List ...