Refer to the flow tables provided with your machine to determine the proper

valve setting to produce your desired flow rate.

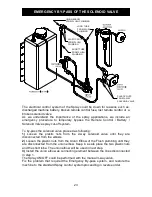

For easier procedure, the calibration is performed thru the flush line, as following:

10) Check the position of the liquid level or “initial” mark (indicated as Mark (i) in

next diagram).

11) With the engine running, move the spray switch at the remote control to the

“ON” position for one minute.

20

6) Loosen the jam nut and rotate the

metering - valve knob to the valve setting

to obtain the desired flow rate according to

the flow table. Tight down the jam nut to

prevent the valve setting from accidentally

be changed

7) Rotate the lever of the 3-way valve to

the flush position (pointing up).

8) With the engine running, move the

spray switch at the remote control to the

“ON” position.

9) Let the machine spray for few seconds

to remove any air bubbles from the tube,

then turn the Spray OFF.

1) Locate the machine in an open and well

ventilated place.

2) Verify that the spray switch at the remote

control is in the “OFF” position.

3) Remove the end of the flush tube from

the tube holder (see diagram).

4) Prepare a graduate cylinder or container

with at least 10 oz (300 ml) of formulation.

5) Insert the end of the Flush Tube into the

container with formulation.

MACHINE CALIBRATION

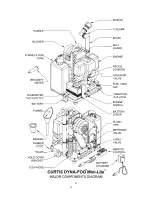

3-WAY VALVE

TUBE

HOLDER

JAM

NUT

METERING

VALVE

KNOB

FLUSH

TUBE

Summary of Contents for 1 Series

Page 1: ......

Page 7: ...7 ...

Page 8: ...8 8 ...

Page 35: ...35 ...

Page 36: ...36 ...

Page 37: ...37 ...

Page 38: ... 38 ...

Page 39: ...39 ...

Page 40: ...40 ...

Page 41: ...41 ...

Page 42: ...42 ...

Page 43: ... 43 ...

Page 44: ... 44 ...

Page 45: ... 45 ...

Page 46: ...4 ...

Page 47: ...47 ...

Page 48: ...48 ...

Page 49: ...49 ...

Page 50: ...50 ...

Page 52: ...cccjlqvqwqxzc x vlj z l lqvqwq j z jklmnooo pw t p yvxmkrq vvrxmyz wzvwmj rrvqmm mmks wvm 52 ...

Page 55: ...cccjlqvqwqxzc x vlj z l lqvqwq j z jklmnooo k vrmyqyzv xm swmksrzvwmm mmks wvmn 55 ...