INSTALLATION & OPERATION MANUAL 10211 REV 0 (04/21)

PAGE

5

OF 20

E

lectric

C

ounter

P

an

S

teamers

D

escription

The model EPX-3 steamer comes equipped with a standard 9.0 kW heating block that can be reduced to 6 kW on

single phase supplies. Model EPX-5 steamer comes equipped with a standard 15.0 kW heating block that can be

reduced to 10 kW on single phase supplies.

Your new steamer has been designed and manufactured to meet the toughest industry standards. The best possible

workmanship and materials along with laboratory tests have been utilized in its design.

Proper installation, care and maintenance will give you years of reliable, trouble free operation.

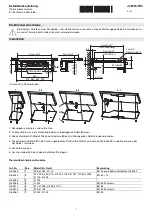

The EPX-3 and EPX-5 are electric fired pressureless steam cookers. The cooking compartments are equipped with

a three-piece door with inner gasket plate isolated from the exterior surface. Door latch operates by slam action for

positive sealing of the door. Operating controls are displayed on a front-mounted panel and include indicator lights

for ready and cooking modes, a timer to set cook times and an illuminated rocker mode selection switch for TIMED

COOKING, OFF and CONSTANT STEAM.

B

asic

F

unctioning

The cooker is ready for operation when the READY light comes on.

At the end of the set interval, timer contacts switch to shut off the cooking operation and sounds a signal buzzer and will

maintain a safe food holding temperature at or above 150̊F. The buzzer is silenced by returning the timer dial to the OFF

position. The READY light will be illuminated.

I

NTRODUCTION

I

N

troduction