14

English

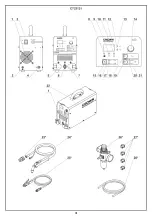

23

Protective collar *

24

Cutting torch (assembled) *

25

Earth clamp (assembled) *

26

Pressure reducting valve (assembled) *

27

Hose clamp *

28

Hose *

29

Grounding wire *

30

Plug *

31

Connection pipe of pressure reducting valve *

32

Manometer *

33

Bracket *

34

Screw *

35

Mounting nut *

36

Protective cover *

37

Cutting torch body *

38

Nozzle *

39

Diffuser *

40

Electrode *

41

Allen key *

42

Button of torch

43

Cutting torch cable connector nut *

44

Cutting torch control cable connector nut *

45

Valve *

46

Condensate drain button *

* Optional extra

Not all of the accessories illustrated or described

are included as standard delivery.

Installation and regulation of machine

elements

Before carrying out any works on the machine it

must be disconnected from the mains.

Do not draw up the fastening elements

too tight to avoid damaging the thread.

Mounting / dismounting / setting-up of

some elements is the same for all ma-

chine models, in this case specific mod

-

els are not indicated in the illustration.

Mounting / dismounting of a plug, current-carrying

cable, stationary network connection

Some machine models are supplied without plugs

and / or current-carrying cables - they must be installed

before the beginning of the operation�

Machines can also be connected to the network on a

stationary basis (not through a socket)�

Note: the stationary connection of the

machine to the network as well as instal-

lation or replacement of current-carrying

cables, plugs and other electrical units

must be performed only by a qualified electrician or

circuit installer authorized to perform such works.

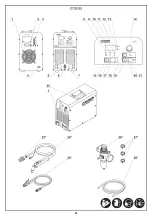

Connection to the grounding loop (see fig. 1)

Using grounding bolt

2

connect one grounding wire

clamp

29

to the machine (see fig. 1). Connect the sec

-

ond grounding wire clamp

29

to the working grounding

loop�

Compressor connection (see fig. 2-4)

•

Extract plugs

30

(see fig. 2.1).

•

Wind teflon tape (for tightening) around threaded

ends of connection pipes

31

and the threaded end of

manometer

32

(see fig. 2.2).

•

Screw connection pipes

31

and manometer

32

in

the pressure reducting valve body

26

and tighten them

with a wrench (see fig. 2.3).

•

Using screws

34

, fix bracket

33

as shown in fig. 2.4.

•

Unscrew the mounting nut

35

, install pressure re-

ducting valve

26

and tighten mounting nut

35

(see

fig. 2.5).

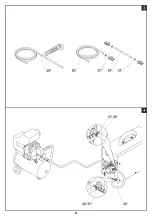

•

Cut hose piece

28

to the length necessary for con-

necting the outlet connecting pipe

31

("OUT" marking)

of pressure reducting valve

26

with connecting pipe

4

�

The second piece of hose

28

will be connected to the

compressor and inlet connecting pipe

31

("IN" mark-

ing) of pressure reducting valve

26

(see fig. 3-4). Put

clamps

27

on where hose

28

ends�

•

Connect the hoses

28

as shown in fig. 4. Fix hose

28

ending on the connecting pipes with clamps

27

�

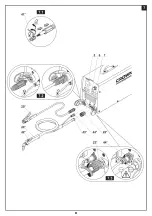

Cutting torch disassembly / assembly (see fig. 5-6)

[CT33131]

•

Unscrew protective cover

36

(see fig. 5).

•

Remove nozzle

38

, diffuser

39

and electrode

40

�

•

If the details are well worn or damaged, replace

them�

•

Assembly should be done in reverse sequence�

[CT33132]

•

Unscrew protective cover

36

(see fig. 6).

•

Unscrew nozzle

38

and electrode

40

from torch

body

37

�

•

If the details are well worn or damaged, replace

them�

•

Assembly should be done in reverse sequence�

Connecting / disconnecting cables (see fig. 7)

•

If necessary to connect connector to earth clamp ca-

ble

25

perform the operations, shown in fig. 7.1.

•

Open protective cover of socket

5

and attach earth

clamp

25

to the machine as shown in fig. 7.2.

•

Connect the cutting torch

24

to the machine (see

fig. 7.3):

•

connect a cutting torch control cable� Set a control

cable connector in socket

6

and tighten a nut

44

by

hand� During installation, pay attention that locating

tab inside of a socket fits a location slot of the cable

connector;

•

put the protective collar

23

on the screw nut

43

;

•

open protective cover of socket

7

;

•

put the screw nut

43

(by turning protective col-

lar

23

) on the connector thread

7

(see fig. 7.3), and

tighten it manually�

•

Disconnect of the cables in a reverse order�

Initial operating of the machine

Before starting the operation the following steps are

necessary:

•

always use the correct supply voltage: the power

supply voltage must match the information quoted

on the machine body;

Summary of Contents for CT33131

Page 1: ......

Page 3: ...3 ...

Page 4: ...4 ...

Page 5: ...5 ...

Page 6: ...6 ...

Page 7: ...7 ...

Page 8: ...8 ...

Page 9: ...9 ...

Page 49: ...49 ...

Page 50: ...50 ...

Page 51: ...51 ...

Page 52: ...52 ...

Page 53: ...53 ...

Page 54: ...54 ...

Page 55: ...55 ...

Page 56: ...56 ...

Page 57: ...57 ...

Page 58: ...58 ...

Page 59: ...59 ...

Page 60: ...60 ...

Page 61: ...61 ...

Page 62: ...62 ...

Page 63: ...63 ...

Page 64: ......