32

33

18/09/2016

LP-OMLINK-B

SECTION 8: LUBRICATION AND

MAINTENANCE

Daily Sprayer maintenance

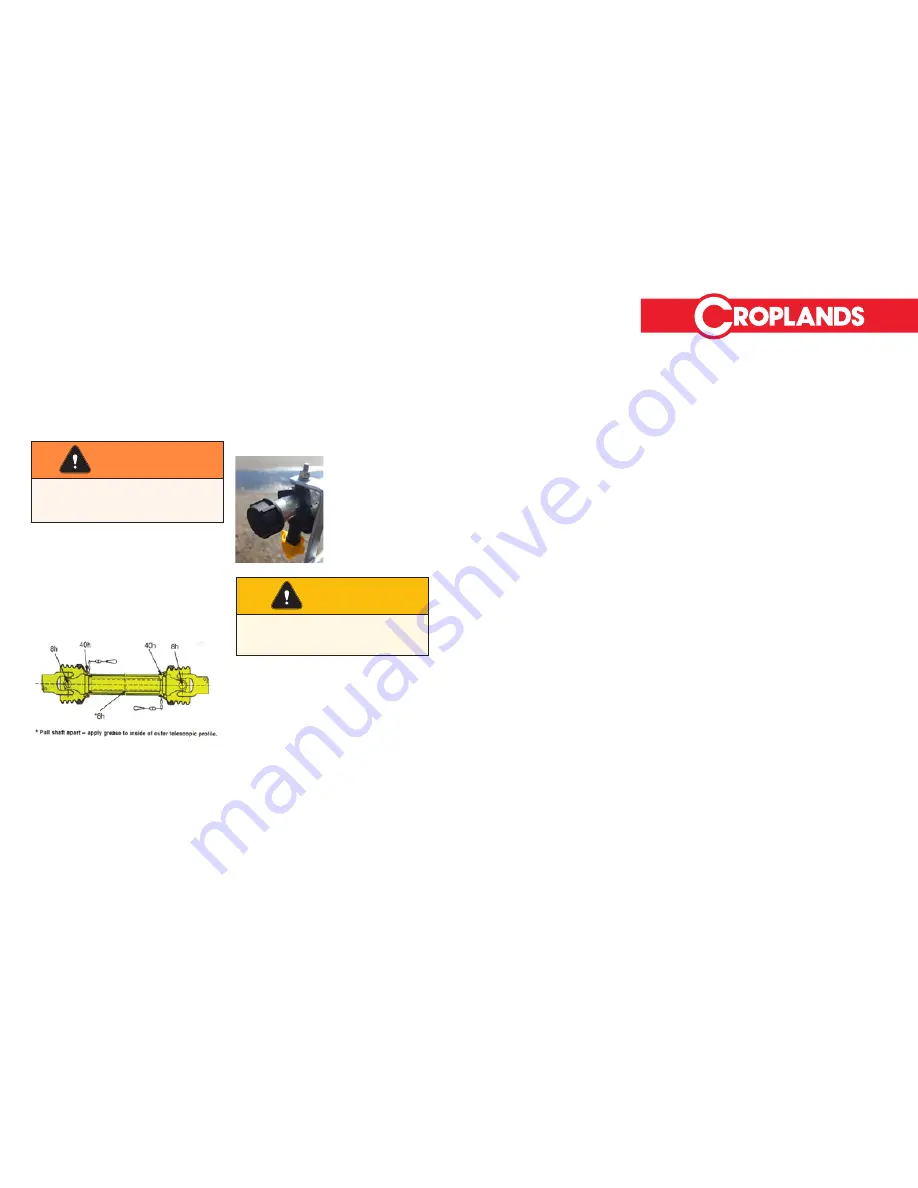

In the first few days of sprayer usage, thoroughly

check the machine before starting each day of

spraying. Check all nuts and bolts and check

plumbing for leaks. Grease the PTO shaft at the time

intervals shown on the diagram below. The diagram

is only a guide, greasing may need to be more

frequent if spraying under extreme conditions.

Pump

Check the oil level on the pump sight gauge and

top up with SAE 20/40 multi grade engine oil if

needed.

Filters

It is important to clean filters daily as they can have

a major impact on your sprayer’s performance.

Wash them out with a soft brush and constantly

CAUTION

Do not leave water in the machine,

particularly in cooler climes as this can

freeze and ruin the pump.

WARNING

Make sure the tractor is switched off, the

machine is lowered to the ground and

the PTO drive shaft is disconnected.

check for holes or tears. Clean the suction filter

every time the tank is filled and at the end of the

days spraying. Make sure O rings are in good

condition and grease them with O ring grease in

necessary. Clean out nozzle filters if installed. See

page 22 for picture of filter screen.

Spray lines

Never leave chemicals

in the tank or the pump.

Rinse the tank out

completely with fresh

water and operate

machine to clear all spray

lines. Remove boom lines

caps if you have a boom

fitted and flush boom lines.

Annual sprayer maintenance

General sprayer care

When spraying season has finished, clean the

machine completely.

Check all electrical fuses as these can easily blow if

corroded in the off season.

Pump

Flush and drain the pump completely before

storage. Check the valves and diaphragms for wear

and damage before the start of the new season. Set

the air pressure in the chamber to around 10 – 20%

of the usual operating pressure. Drain the oil before

the commencement of the next season and replace

completely with new oil (SAE 20/40 multi grade

engine oil).

NOTES: