7

In the event of an overtemperature, the source of this

condition should be determined and rectified immediately.

Thermal protection shall not be used as a motor overload

device. A separate motor overload device must be

provided in accordance with NEC codes.

DO NOT

LET THE PUMP CYCLE OR RUN IF AN OVERLOAD

CONDITION OCCURS !

Thermal Protection (SGV2022L) -

The normally closed

(N/C) thermal overload is embedded and wired in series

with the motor windings. It monitors for excessive heat

and/or current draw in the event an overload condition

occurs. The thermal overload will trip when the windings

become too hot causing the pump to stop, and will

automatically reset itself when the pump motor cools

to a safe temperature. In the event of an overload, the

source of this condition should be determined and rectified

immediately. The thermal protection provided in the pump

can be used as a motor overload device. A separate

motor overload device is not required.

DO NOT LET THE

PUMP CYCLE OR RUN IF AN OVERLOAD CONDITION

OCCURS !

Moisture Sensors: (Optional) -

A normally open (N/O)

detector is installed in the pump seal chamber which will

detect any moisture present. It is recommended that this

detector be connected in series to an alarm device or

the motor starter coil to alert the operator that a moisture

detect has occurred. In the event of a moisture detect,

check the individual moisture sensor probe leads for

continuity, (∞ resistance = no moisture ) and the junction

box/control box for moisture content. This situations may

induce a false signal in the moisture detecting circuit. If

none of the above tests prove conclusive, the pump(s)

should be pulled and the source of the failure identified

and repaired.

IF A MOISTURE DETECT HAS OCCURRED SCHEDULE

MAINTENANCE AS SOON AS POSSIBLE.

Wire Size -

If additional cable is required consult a

qualified electrician for proper wire size.

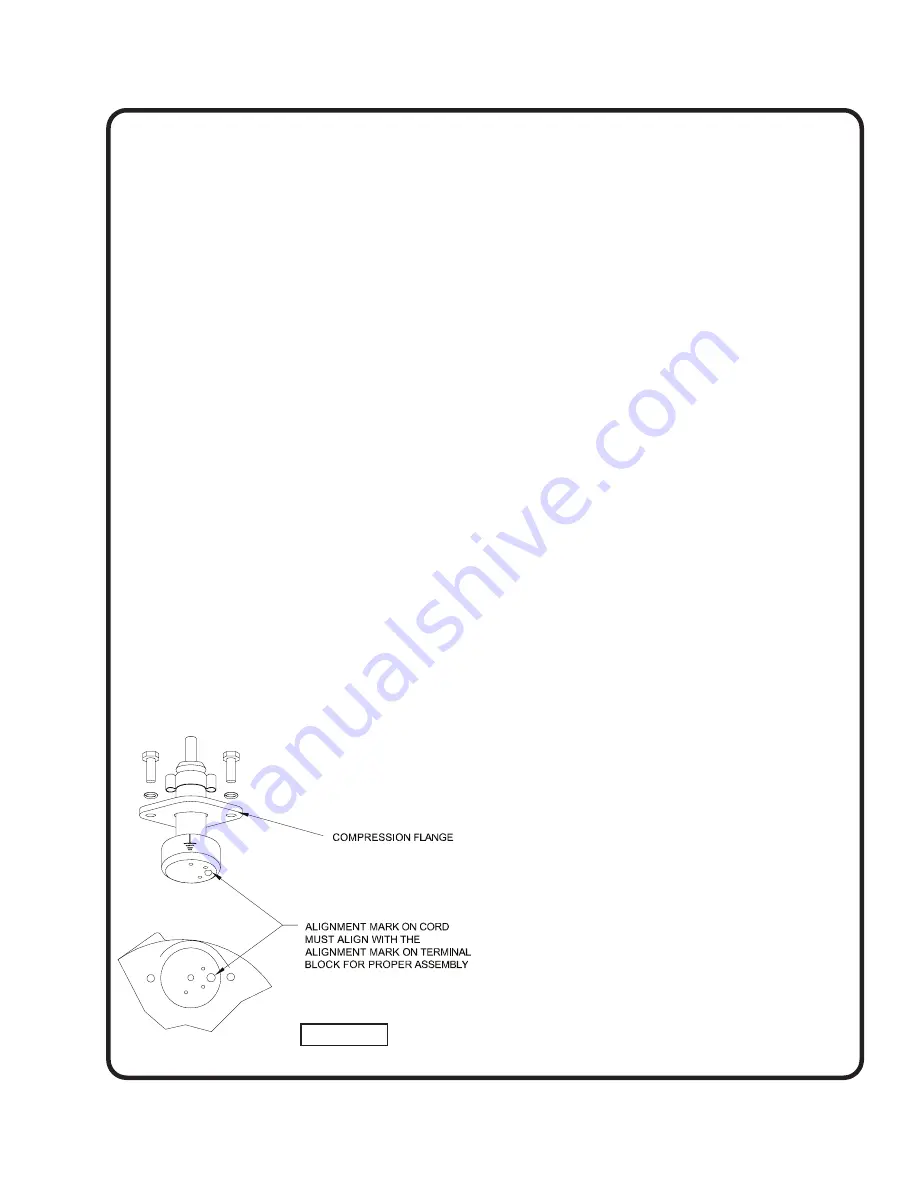

Cable Connections:

Power/Control Cable- Insert female end of cable plug into

housing bore aligning alignment mark with hole in terminal

block see Figure 2. Tighten bolts on compression flange

until flush with motor housing.

NOTES:

FIGURE 2