If the pump is inoperative for a long period of time, or

appears not to use any grease, remove and clean the cup

thoroughly. Caked grease in the cup can create a problem

of non-lubrication to the seal.

Under normal conditions, a grease cup full of grease will

last three to four months. If a grease seal requires grease

every day, and it is not leaking past the outer lip seal it

indicates that the seal is wearing out. The internal pressure

of the pump will often force the cup plunger out when the

seal leaks badly.

D-2) Shaft Seal Replacement:

All parts of the pump are easily dismantled by simply

removing nuts and screws. Rotating parts of the shaft seal

grip the shaft by friction and may be frozen to the shaft

through long usage.

If the mechanical shaft seal is not leaking and it is

necessary to dismantle part of the pump for inspection or

cleaning

DO NOT

disturb the shaft seal other than its

spring if the impeller is removed. Once a shaft seal has

been in operation it cannot be removed and replaced

without leaking.

CAUTION !

HANDLE PARTS WITH EXTREME CARE.

DO NOT SCRATCH OR MAR LAPPED SURFACES.

It is recommended to remove the pump side from the

support bracket. After the pump has been disassembled

make sure that the shaft and seat areas in the pump side

are as clean as possible. The shaft must not be sharp, but

neatly rounded and polished to a 1/32" radius. This radius

and the shaft, on which the rubber bellows grips, must be

polished with 180 to 240 grit emery cloth. The seal will

install relatively easy if the shaft is properly polished.

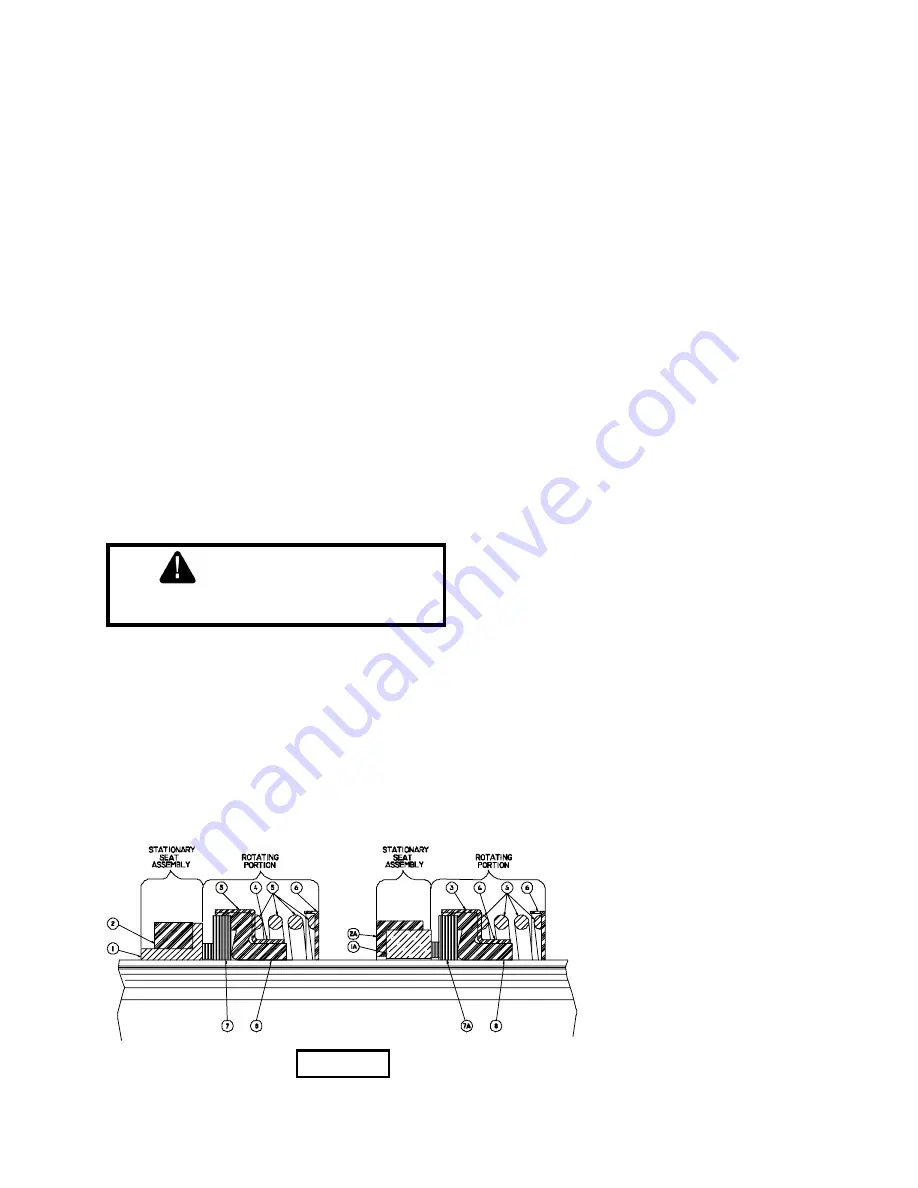

Install the seat assembly (1 and 2 or 1A and 2A, see Figure

2) in pump side adapter (12) using SAE# 10 oil on the

rubber parts. They may install easier by first inserting the

rubber part and then sliding the seat part into the rubber.

All of this must be done with the

fingers only

.

Now assemble the spring and rotating portion of the seal

onto the impeller shaft (19). Lubricate the impeller shaft

(19) and the inside of the bellows each with 2 or 3 drops

of SAE# 10 oil. Install this assembly into adapter (12), this

may take several minutes, therefore, oscillate the seal

back and forth on the shaft to make sure it does not stick

to the shaft until gage pin is in place and the clamp

tightened.

If for any reason the gage pin does not give proper

clearance, quickly adjust the impeller clearance before the

rubber bellows seats on the shaft.

D-3) Impeller:

These pumps have their impellers threaded on with right

hand threads.

The clearance between an open faced impeller and its

wear surface in the volute is set at the factory at

approximately .015 inches. This clearance is re-adjustable

by relocating the shaft at the clamping arrangement. In

cases where much sand is being pumped, close

clearances may bind the impeller and volute and overload

the motor. It may be necessary to provide extra clearance

on these.

When reassembling a dismantled pump, clean all parts

and especially areas where gaskets and o-rings are

located. Grease all gaskets and o-rings and areas where

o-rings must slide when assembling.

FIGURE 2

1 - Ni-Resist Stationary Seat

1A- Ceramic Stationary Seat

2 - Buna-N Seat Ring

2A- Buna-N Seat Cup

3 - Stainless Retainer

4 - Stainless Drive Band

5 - Stainless Spring

6 - Stainless Springholder

7 - Crane-Carb® Mating Ring

7A- Carbon Mating Ring

8 - Buna-N Bellows

Cross Section of Seals.

Two Styles Shown.

7

Summary of Contents for burks pumps WB12

Page 8: ...FIGURE 3 8 ...