9

Position unit upright, using blocks to avoid resting unit on

shaft. Remove gland nut (12b), friction rings (12c) and

grommet (12d) from motor housing (11), see Figure 8.

Remove socket head cap screws (36) and lift motor housing

(11) from lower end bell (10). Slide motor housing (11) up

cable (12), until wire connectors and ground screw are

exposed. Remove cable lead wires from motor lead wires

by disconnecting wire connectors (19) and ground screw

(20) from motor (14). The wiring connections should be

noted to insure correct connections when reassembling.

Motor -

Remove the motor bolts and lift motor stator from

motor rotor and lower end bell (10). Unscrew conduit

bushing (16) from lower end bell (10) and lift motor rotor,

shaft, bearing (21), rotating portion of seal (1), washers (25)

& (33), and conduit bushing (16) from lower end bell (10).

Inspect windings for shorts and check resistance values.

Check rotor for wear, if rotor or the stator windings are

defective, the complete motor must be replaced.

To test the temperature sensor (if equipped), check the

continuity between the black and white wires. If found to be

defective contact a motor service station or Barnes Service

Department. Check motor capacitor (18) on single phase

units with an Ohm meter by fi rst grounding the capacitor

by placing a screwdriver across both terminals and then

removing screwdriver. Connect Ohm meter (set on high

scale) to terminals, if needle moves to infi nity ( ∞ ) then

drifts back, the capacitor is good. If needle does not move

or moves to infi nity (∞) and does not drift back, replace

capacitor (18).

Seal -

Remove rotating member (1a), spring (1c) and

retaining ring (1d) from shaft. (see Figure 5). Examine all seal

parts and especially contact faces. Inspect seal for signs of

wear such as uneven wear pattern on stationary members,

chips and scratches on either seal face.

DO NOT

interchange

seal components, replace the entire shaft seal (1).

If replacing seal, remove stationary (1a) from lower end bell

(10) by prying out with fl at screwdriver.

CAUTION ! - Handle seal parts with extreme

care. DO NOT scratch or mar lapped surfaces.

Bearing -

Examine bearing (21) and replace if required. If

replacement is required, remove bearing (21) from motor

shaft using a wheel puller. Washers (25), (33) and conduit

bushing (16) can now be removed from motor shaft.

IMPORTANT ! - All parts must be clean before

reassembly.

F-3.2) Reassembly:

Bearing -

When replacing bearing, be careful not to damage

the rotor or shaft threads. Clean the shaft thoroughly. Slide

conduit bushing (16) and washers (25), (33) over motor shaft.

Apply adhesive compound to the shaft and press bearing

(21) on the motor shaft, position squarely onto shaft applying

force to the inner race of the bearing only, until bearing seats

against shoulder of the shaft.

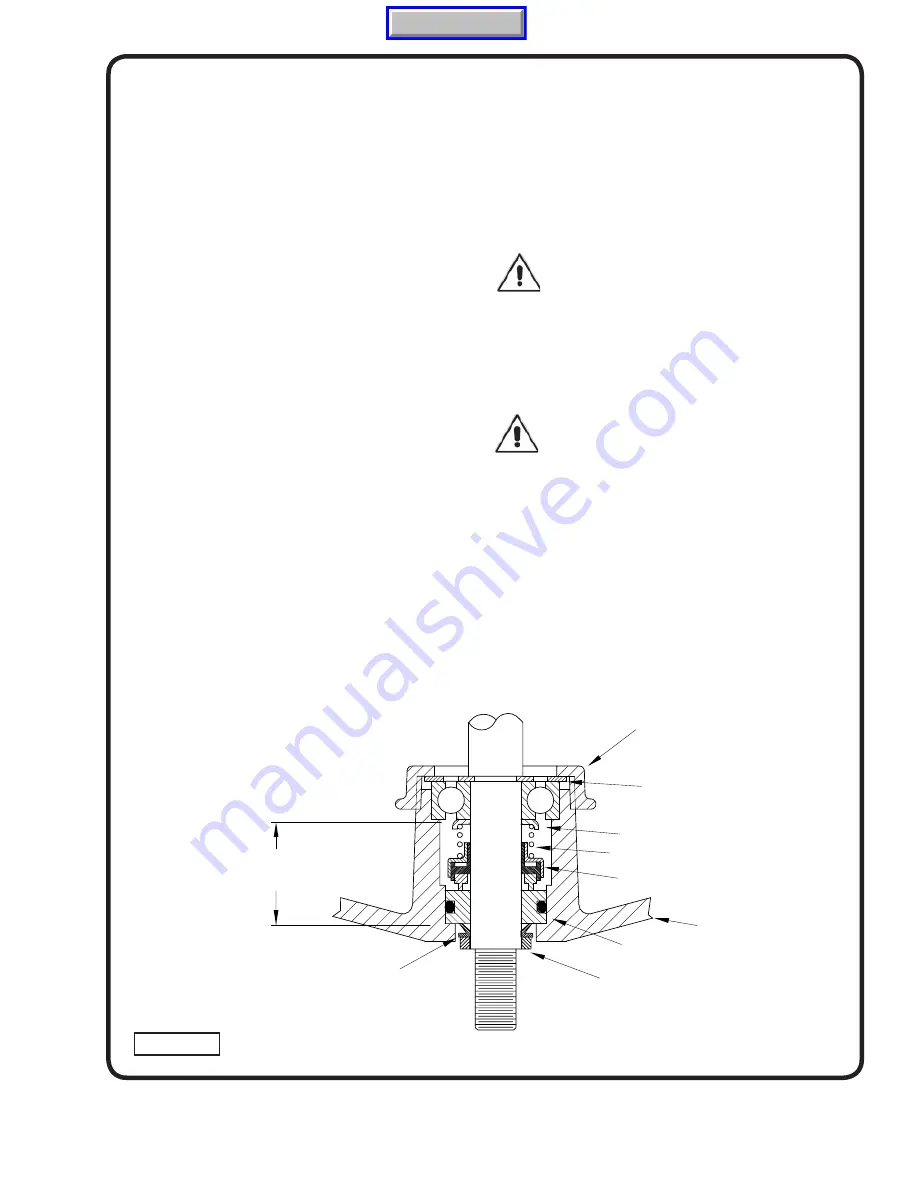

SEAL ASSEMBLY (1)

RETAINING RING (1D)

LOWER END BELL (10)

SPRING (1C)

ROTATING MEMBER (1B)

STATIONARY (1A)

CONDUIT BUSHING (16)

WASHER (25) & (33)

SPACER (32) and

SHIMS (39) & (40)

EXCLUSION SEAL (31)

MOTOR END

(INBOARD END)

PUMP END

(OUTBOARD END)

FIGURE 5

Manual Index

Summary of Contents for Barnes SE51 Series

Page 13: ...13 FIGURE 10 Manual Index ...

Page 14: ...14 FIGURE 11 Manual Index ...