7

RECEIVING/UNPACKING:

Upon receiving the pump, it should be inspected for dam-

age or shortages. If damage has occurred,

fi

le a claim

immediately with the company that delivered the pump.

Unpack pump and record pump serial and model number

before installing. If the manual is removed from the pack-

aging, do not lose or misplace.

STORAGE:

Short Term-

For best results, pumps can be retained in

storage, as factory assembled, in a dry atmosphere with

constant temperatures for up to six (6) months.

Long Term-

Any length of time exceeding six (6) months,

but not more than twenty-four (24) months. The units

should be stored in a temperature controlled area, a roofed

over walled enclosure that provides protection from the

elements (rain, snow, wind-blown dust, etc.), and whose

temperature can be maintained b40 deg. F and

+120 deg. F. If extended high humidity is expected to be

a problem, all exposed parts should be inspected before

storage and all surfaces that have the paint scratched,

damaged, or worn should be recoated with a air dry

enamel paint. All surfaces should then be sprayed with a

rust-inhibiting oil.

Pump should be stored in its original shipping container.

On initial start up, rotate shaft by hand to assure seal

and motor rotate freely. If it is required that the pump be

installed and tested before the long term storage begins,

such installation will be allowed provided:

1.) The pump is not installed under water for more than

one (1) month.

2.) Immediately upon satisfactory completion of the

test, the pump is removed, thoroughly dried,

repacked in the original shipping container, and

placed in a temperature controlled storage area.

3.) Before placing pump into service, pump should be

brought to operational temperature range.

Excessive or direct heating or cooling should

NOT

be

used.

OPERATION TEMPERATURE RANGE:

+35ºF (2ºC) to

104ºF (40ºC).

SERVICE CENTERS:

For the location of the nearest Barnes Service Center,

check your Barnes representative or Crane Pumps

& Systems, Inc., Service Department in Piqua, Ohio,

telephone (937) 778-8947 or in Brampton, Ontario,

Canada (905) 457-6223.

INSTALLATION:

Location -

The pump is designed with pipe legs to

keep a minimum of 3 inch clearance.

THIS PUMP

MUST BE INSTALLED WITH A MINIMUM OF 3

INCHES CLEARANCE UNDER THE PUMP FOR THE

ENTRANCE OF SEWAGE SOLIDS.

Discharge -

Assemble discharge piping or hose assembly

(whichever is required by your application), to the pump.

Discharge piping should be as short as possible. Both a

check valve and a shut-off valve are required for each pump

being used. The check valve is used to prevent back

fl

ow

into the sump. Excessive back

fl

ow can cause

fl

ooding and/

or damage to the pump. The shut-off valve is used to stop

system

fl

ow during pump or check valve servicing. If pump

is installed with a discharge hose rather than a moveable

fi

tting assembly, make sure the discharge pipe has a 1/8”

dia. hole approx. 5” from end nearest volute and oriented

towards the pump body.

ELECTRICAL CONNECTIONS:

Pump Cords -

The quick connect cord assembly mounted

to the pump must

NOT

be modi

fi

ed in any way except for

shortening to a speci

fi

c application. Any supply cables con-

nections between the pump and the control panel must be

made in accordance with the National Electric Code or the

Canadian Electric Code and all applicable state, province

and local electric codes. It is recommended that a junction

box, be mounted outside the sump or be of at least Nema

4 (EEMAC-4) construction if located within the wet well.

DO NOT USE THE POWER OR CONTROL CABLES TO

LIFT PUMP!

Overload Protection -

The type of in-winding overload

protector used is referred to as an inherent overheating

protector and operates on the combined effect of temperature

and current. This means that the overload protector will trip

out and shut the pump off if the windings become too hot,

or the load current passing through them becomes too high.

It will then automatically reset and start the pump up after

the motor cools to a safe temperature. In the event of an

overload, the source of this condition should be determined

and recti

fi

ed immediately.

DO NOT LET THE PUMP CYCLE

OR RUN IF AN OVERLOAD CONDITION OCCURS !

Wire Size -

If additional cord is required consult a quali

fi

ed

electrician for proper wire size.

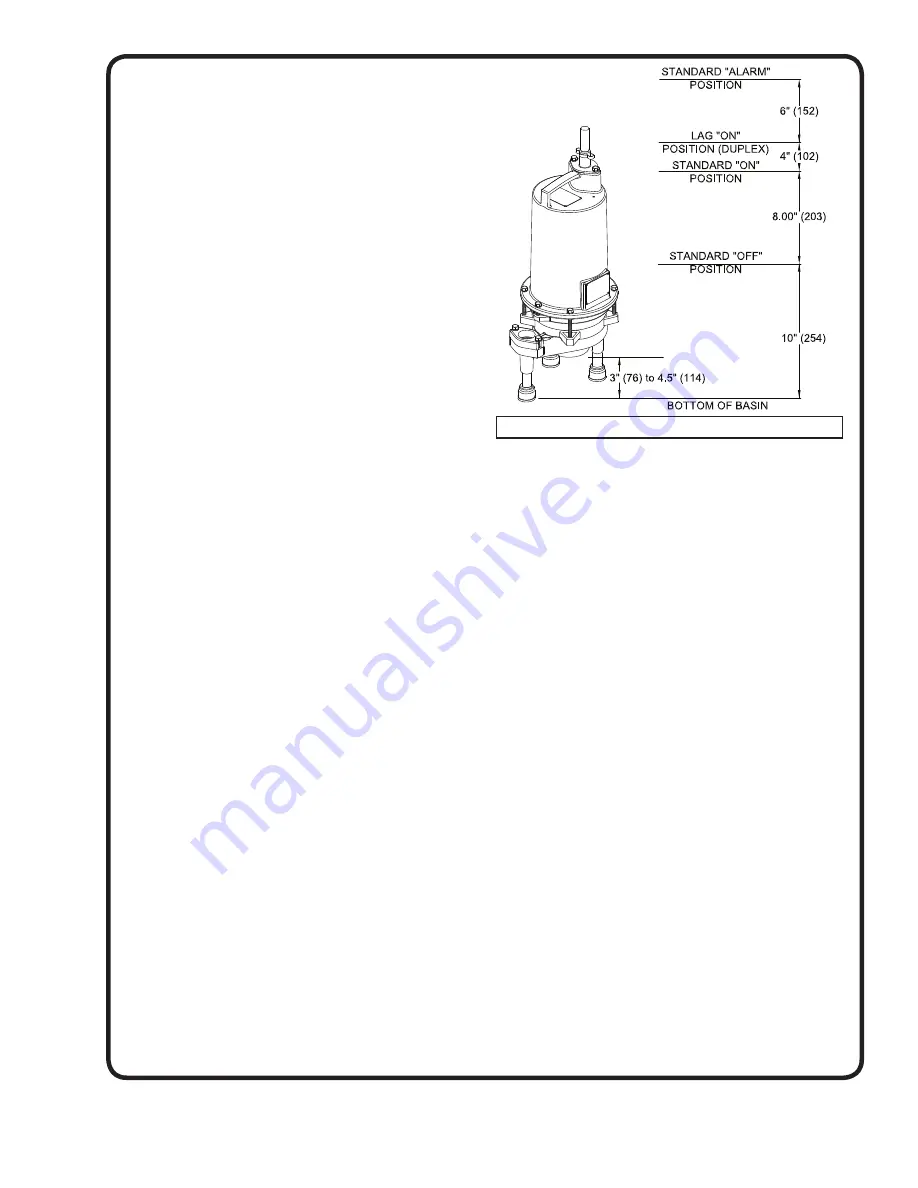

FIGURE 3 - L Series

(For Automatic see Level Control manual)

Summary of Contents for Barnes PGPH Series

Page 10: ...10 FIGURE 6 ...

Page 12: ...Notes ...