7

C-5) Pump Body Leg Removal:

It is advisable to remove the pump body legs if they

are within one inch of the fl oor when the pump is in the

operating position. This affects the following pump models

when installed in standard applications:

6SE____EHA and 6XSE____EHA. Remove 6 hex head

bolts and 6 washers holding legs in place. Remove legs

from pump body and replace bolts

and washers.

C-6) Thread Locking Compound:

Thread locking compound can be purchased locally

in small quantities. When used, they provide an extra

assurance the bolted joint will remain together. These

Anaerobic Adhesive/Sealant Thread Locking compounds

are available in several grades from several suppliers and

recommendations are as follows:

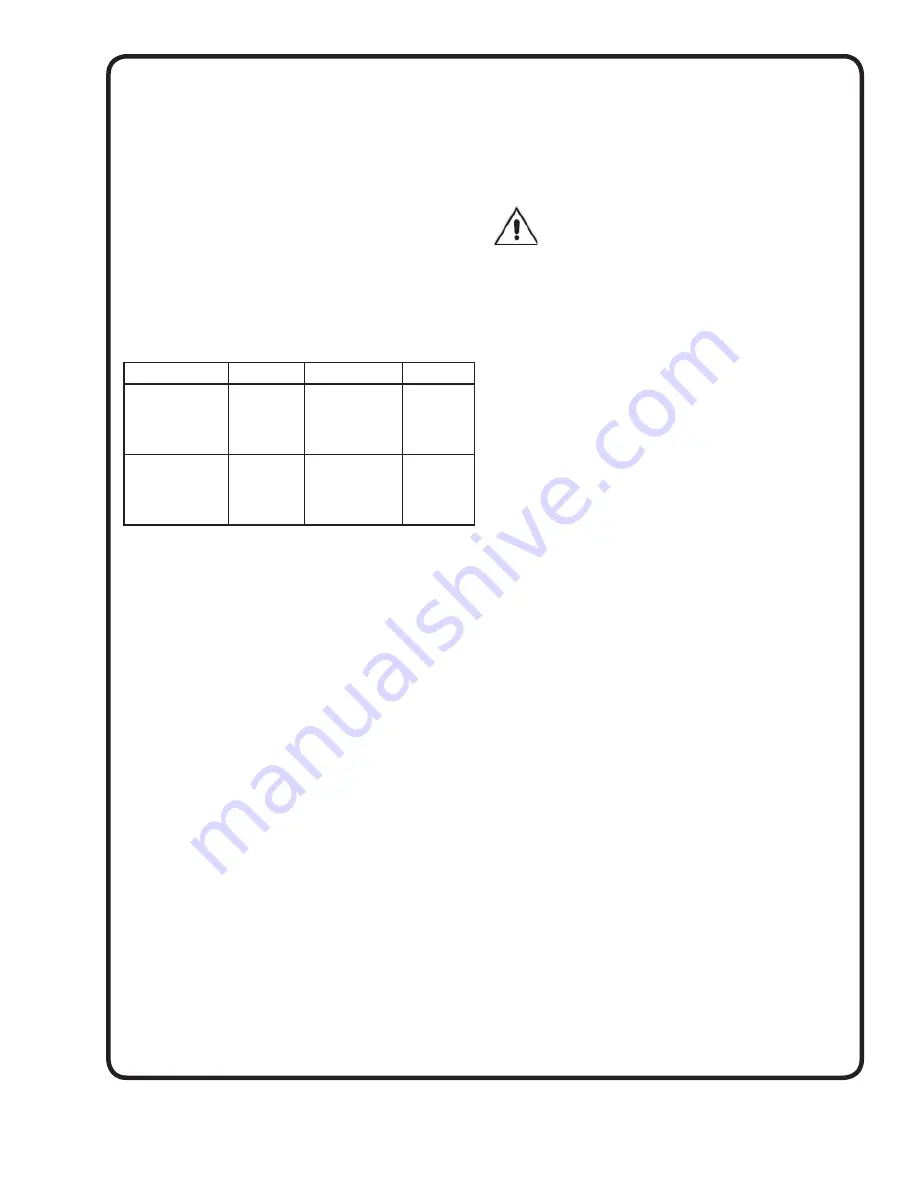

DESCRIPTION LOCTITE® PERMA-LOC® STALOC®

Thread Locking

Compound

#242 (General

Purpose)

242

MM5

T42

Thread Locking

Compound #

RC609 (High

Strength)

RC609

HM128

T70

C-7) Lifting Chain Installation:

For models 6SE_____L and 6SE____HL, optional lifting

chain (5/16” dia. proof coil chain, hot galvanized) is looped

through lifting yoke and fastened together with two 3/8”

steel, zinc plated cold shut. Force cold shut closed and weld

together.

For models 6SE____EHA (Standard units) and models

6XSE____A and 6XSE____EHA, (Non-Sparking units),

optional lifting chain (5/16, or 3/8” dia. proof coil chain, hot

galvanized, sized to match lifting chain assembly supplied

with pump) is fastened to pump chain with a 3/8, or 7/16”

steel, zinc plated cold shut. Cold shut is supplied with pump

motor chain.

NOTE:

Pumps are supplied from manufacturer

with motor chain aligned with discharge fl ange (see Figure

6). Find center of pump motor chain. Find chain link 1

to 1-1/2 links away from center on side opposite pump

discharge. Insert cold shut in this link. Attach to lifting chain.

Force cold shut closed and weld together. When pump is

lifted, pump discharge should tilt below horizontal centerline

from 5 to 10”.

C-8) Installation Descent Speed:

When lowering pump into wet well on the guide rails, do not

exceed a descent speed of 3.2 inches per second or 16 feet

per minute.

SECTION D: MAINTENANCE AND REPAIR

D-1) Maintenance:

After pump is lifted for inspection, it is recommended any

foreign material be fl ushed from moveable fi tting, guide

plugs, and stationary base elbow face before replacement

in wet well.

D-2) Repair:

NOTE:

All item numbers in ( ) refer to Figure 7.

D-2.1) Moveable Assembly:

To install a new o-ring in moveable assembly (1),

completely remove o-ring (1B) and thoroughly clean

groove recess in moveable (1A).

NOTE: CARE SHOULD BE TAKEN SO DOVE-

TAILED GROOVE IS NOT DAMAGED WHEN

REMOVING O-RING.

Set moveable (1A) with dove-tail groove up on an arbor

press. Shim and/or clamp moveable so sealing face is

level. Run a light bead of quick set adhesive (Aron Alpha

or equivalent) around center of groove bottom. Set o-ring

(1B) over groove. Place a fl at plate over o-ring (1B), center

under press. Using press, force o-ring (1B) into groove.

Hold for around 1 minute to allow adhesive to set.

NOTE:

DO NOT USE EXCESSIVE PRESSURE AFTER O-RING

SLIPS INTO GROOVE.

D-2.2) Stationary Base Elbow:

To replace Guide Plug(s) (2B) on Stationary Elbow (2A),

remove socket head screw (2C). Inspect o-ring (2D) for

damage or cuts and replace if required. Reassemble by

placing guide plug (2B) on stationary (2A), insert screw

(2C) into guide plug and tighten.

D-2.3) Guide Rail Cap:

To replace Guide Plug(s) (3B) on Guide Rail Cap (3A),

remove socket head screw (3C), washer (3E) and nut

(3F). Inspect o-ring (3D) for damage or cuts and replace

if required. Reassemble by placing guide plug (3B) on

tab of bracket (3A), insert screw (3C) thru guide plug

and assemble washer (3E) and nut (3F) onto screw and

tighten.

D-2.4) Intermediate Support :

To replace Guide Plug(s) (9B) on Intermediate support

(9A), remove socket head screw (9C), washer (9D) and

nut (9E). Inspect o-ring (9F) for damage or cuts and

replace if required. Reassemble by placing guide plug (9B)

on tab of bracket (9A), insert screw (9C) thru guide plug

and assemble washer (9D) and nut (9E) onto screw and

tighten.

SECTION E: REPLACEMENT PARTS

E-1) Ordering Replacement Parts:

When ordering replacement parts, always furnish the

following information:

1. Product

Model

2. Part

Description

3. Part

Number

4. Quantity

Required

5. Shipping

Instructions

6. Billing

Instructions

Product improvements are made from time to time. The

latest part design will be furnished as it is interchangeable

with the old part.

Summary of Contents for 091550

Page 4: ...4 inches mm Figure 1 Figure 2 ...

Page 8: ...8 Figure 6 ...

Page 9: ...9 Figure 7 ...

Page 13: ...13 Notes ...

Page 14: ...14 Notes ...