13

SERVICE AND ADJUSTMENTS

CAUTION: Disconnect spark plug wire from spark plug and place wire where it cannot come into

contact with plug.

TILLER

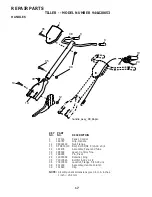

TO ADJUST HANDLE HEIGHT (See Fig. 15)

Factory assembly has provided lowest handle height. Se lect

handle height best suited for your tilling conditions. Handle

height will be different when tiller digs into soil.

•

If a higher handle height is desired, loosen the four

nuts securing handle panel to engine brackets.

•

Slide handle panel to desired location.

•

Tighten the four nuts securely.

HANDLE

PANEL

ENGINE

BRACKETS

NUTS (ALSO 2

ON LEFT SIDE

OF TILLER)

Fig. 15

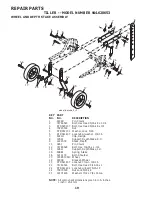

MID-WIDTH TILLING (See Fig. 17)

•

Assemble holes “A” in tine hubs to holes “C” in tine

shaft.

tine_5

A

C

A

C

Fig. 17

NARROW TILLING/CULTIVATING (See Fig. 18)

•

Remove outer tines.

Fig. 18

tine_6

INNER TINES ONLY

TINE ARRANGEMENT

Your outer tines can be assembled in several different ways

to suit your tilling or cultivating needs.

CAUTION: Tines are sharp. Wear

gloves or other protection when han-

dling tines.

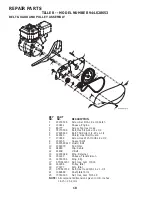

NORMAL TILLING (See Fig. 16)

•

Assemble holes “A” in tine hubs to holes “B” in tine

shaft.

tine_4

OUTER

TINE

HAIRPIN CLIP

A

B

A

B

Fig. 16

INNER TINE

CLEVIS

PIN

NOTE: When reassembling outer tines, be sure right tine

assembly (marked “R”) and left tine assembly (marked “L”)

are mounted to correct side of tine shaft.

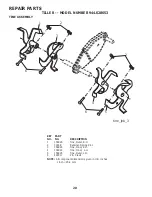

TINE OPERATION CHECK (See Fig. 18)

WARNING: Disconnect spark plug wire

from spark plug to prevent starting while

checking tine operation.

For proper tine operation, forward tine control lever must

be against control body and all slack removed from inner

wire of control cable when control is in the “OFF” (up)

position.

If lever and cable are loose, loosen cable clip at lower end of

cable. Pull up on cable to remove slack, without extending

spring on end of cable, and retighten cable clip.

FINAL CHECK “OFF” POSITION

•

With tine control “OFF” (up), push down on handle to

raise tines off the ground.

•

Slowly pull recoil starter handle while observing tines.

Tines should not rotate.

•

If tines rotate, inner wire of control cable is too tight

which is extending lower spring and engaging tines.

Loosen cable clip and push down on cable only enough

to relieve spring tension. Tighten cable clip.

•

Recheck in “OFF” position and adjust if necessary.