6- ENG

D29783

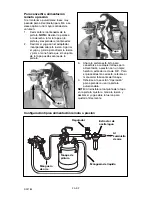

2.

Fill the material cup 3/4 full.

3.

Attach material cup to the lid/gun

assembly and slide release lever

to the left to secure in place.

NOTE:

When replacing lid/gun

assembly make sure bend in material

tube is positioned to the front of the

spray gun as shown.

4. Attach air supply line to 1/4 NPT

air inlet.

5.

See "Operation" Section to learn

how to use the spray gun.

D29783

For Siphon Feed Connection

1.

Remove the material cup from

lid/gun assembly.

NOTE:

Slide

release lever to the right, rotate

lid, and remove material cup.

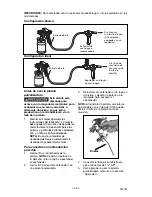

Basic Set Up

Ideal Set Up

Recommended

oil/water extractor

To Air Supply- an

air compressor

equipped with a

regulator

Regulator and

oil/water extractor

To air supply -

hard plumbed

air supply

Air Inlet

Air Inlet

Before Using Spray Gun

This gun is designed

for use with most

finishing materials. It is not

designed for use with corrosive or

highly abrasive materials. Using

these materials can lead to poor

performance and/or failure of this

product.

1. Mix material according the

manufacturer’s instructions.

Mixture should be smooth and

easily pourable. Lumps or foreign

particles should be removed by

straining through a suitable paint

filter.

NOTE:

Using a Sears

Viscosimeter will help in

measuring the viscosity or

thickness of the material.

Bend

IMPORTANT:

The use of a oil/water extractor is recommended. See set

illustrations for examples.

Summary of Contents for 919.155190

Page 27: ...27 SP D29783 NOTES ...

Page 28: ...28 SP D29783 NOTES ...

Page 29: ...29 SP D29783 NOTES ...

Page 30: ...30 SP D29783 NOTES ...

Page 31: ...31 SP D29783 NOTES ...