8

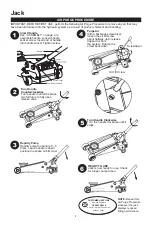

ASSEMBLY

Assembly

INSPECT STANDS BEFORE EACH USE.

DO NOT USE IF BENT, BROKEN OR

CRACKED COMPONENTS ARE NOTED.

ENSURE THAT ALL PARTS MOVE FREELY.

• Align the ratchet side of the ratchet column

with front of jack stand. See Picture 1.

• Raise locking lever and insert ratchet

column into jack stand frame to the lowest

position. Lower the locking lever.

• Press metal tab in to prevent ratchet column

from ever lifting out of stand. See Picture 2.

• Always check the vehicle owners or service

manual for location of proper lift and support

points.

Maintenance

Periodically inspect both stands. Ensure

all parts move freely. Do not apply oil or

grease to any portion of this product. If rust

appears, sand affected area and cover with

suitable utility paint. Please note that there

are no replacement parts applicable to this

equipment. Replacement stands must be

purchased as a matched pair.

Store stands in upright position and in a

clean, dry area.

Inspect jack stand before each use.

DO NOT use if bent, broken or cracked

components are noted. To prevent

corrosion, clean as needed and wipe with

an oily cloth. Keep in a dry area when not

in use.

CAUTION:

Equipment that appears

damaged or worn or operates abnormally

shall be removed from service until repair.

Repair should be made by qualified repair

facility. Annual inspection of the stand is

recommended by a Craftsman repair facility

to ensure that the stand is in optimum

condition and has all correct decals and

safety labels specified by the manufacture

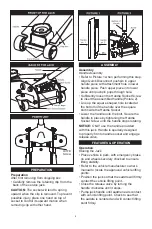

• Put the jack stands on hard level ground.

• Adjust height by pulling up on ratchet

column to raise the height. To lower height,

lift locking lever, lower ratchet column to

desired height, then lower lever. Be sure the

ratchet column locks securely in place.

• Place load on the center of jack stand

saddle. For safety the lifting jack should not

be removed while jack stands are supporting

the vehicle.

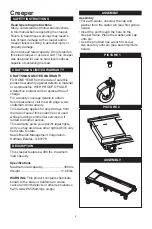

FEATURES & OPERATION

Saddle

Ratchet Column

Locking Lever

Base

Bend metal tab in to

prevent column from

lifting out.

Summary of Contents for 48181

Page 11: ...11 NOTE ...