15

BEVEL CUTTING

Bevel cutting is the cutting operation to cut

a desired angle on the edge of the work

piece.

To perform bevel cutting operation on a

jointer it is recommended to set the cutting

depth between 1/16” and 1/8”.

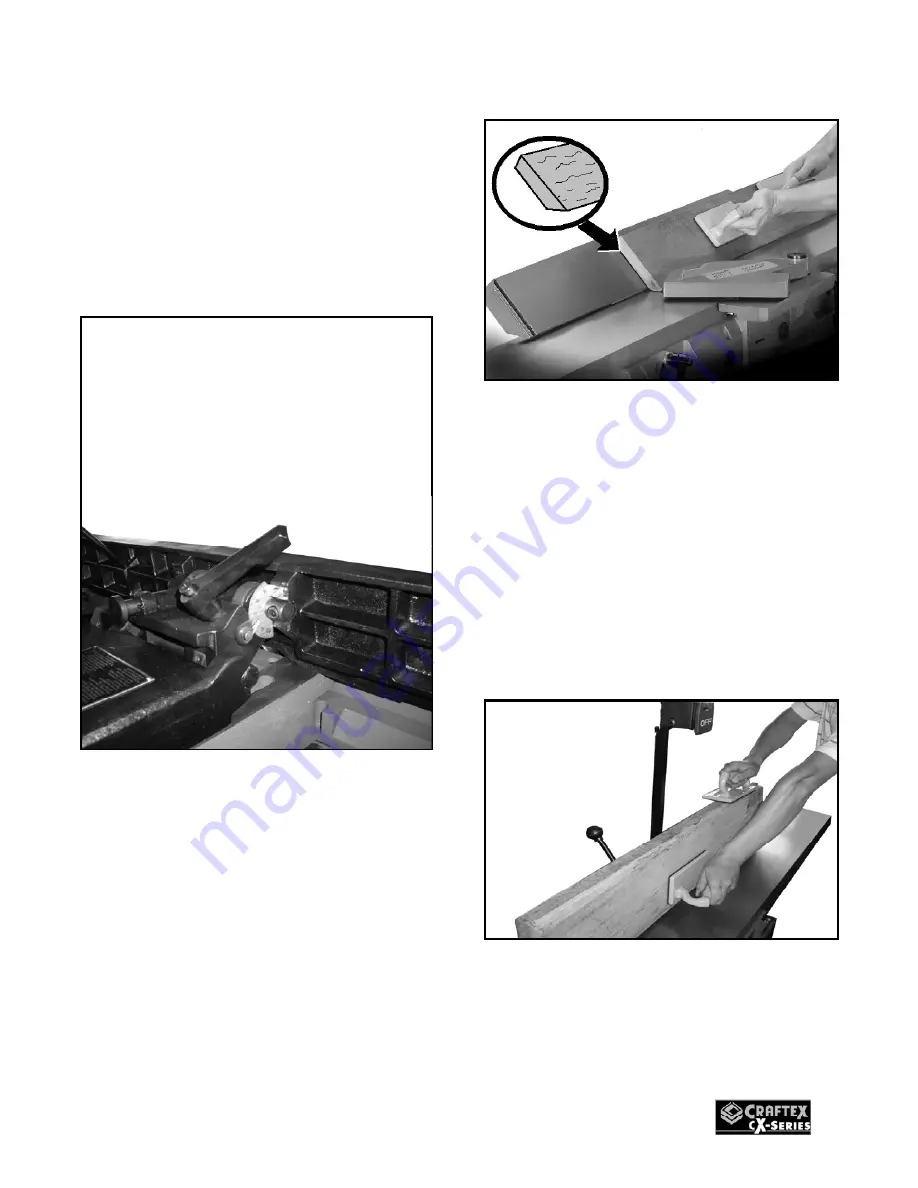

Figure-16 Fence tilt lock

Now, set the fence to your desired angle

and start the jointer. Use push blocks to

push the stock over the cutter-head. If the

stock is cupped, make sure to put the

concave face of the stock flat on the in-feed

table. See figure 17.

Figure-17 Bevel cutting

EDGE JOINTING

Edge jointing is to make the edge of the

stock flat and suitable for joinery or

finishing. To edge joint on the jointer set the

cutting depth to 1/16” & 1/8” and make sure

the fence is set to 90 degrees. Place the

concave face of the stock flat on the in-feed

table and run the jointer. Use push blocks

to push the stock over the cutter head.

Repeat the same procedure until the edge

of the stock is flat.

Figure-18 Edge jointing

The fence of the jointer can be set to

different angles and it has a stop that

can hold the fence in that position so

that it doest not move while operation.