Page of 44

36

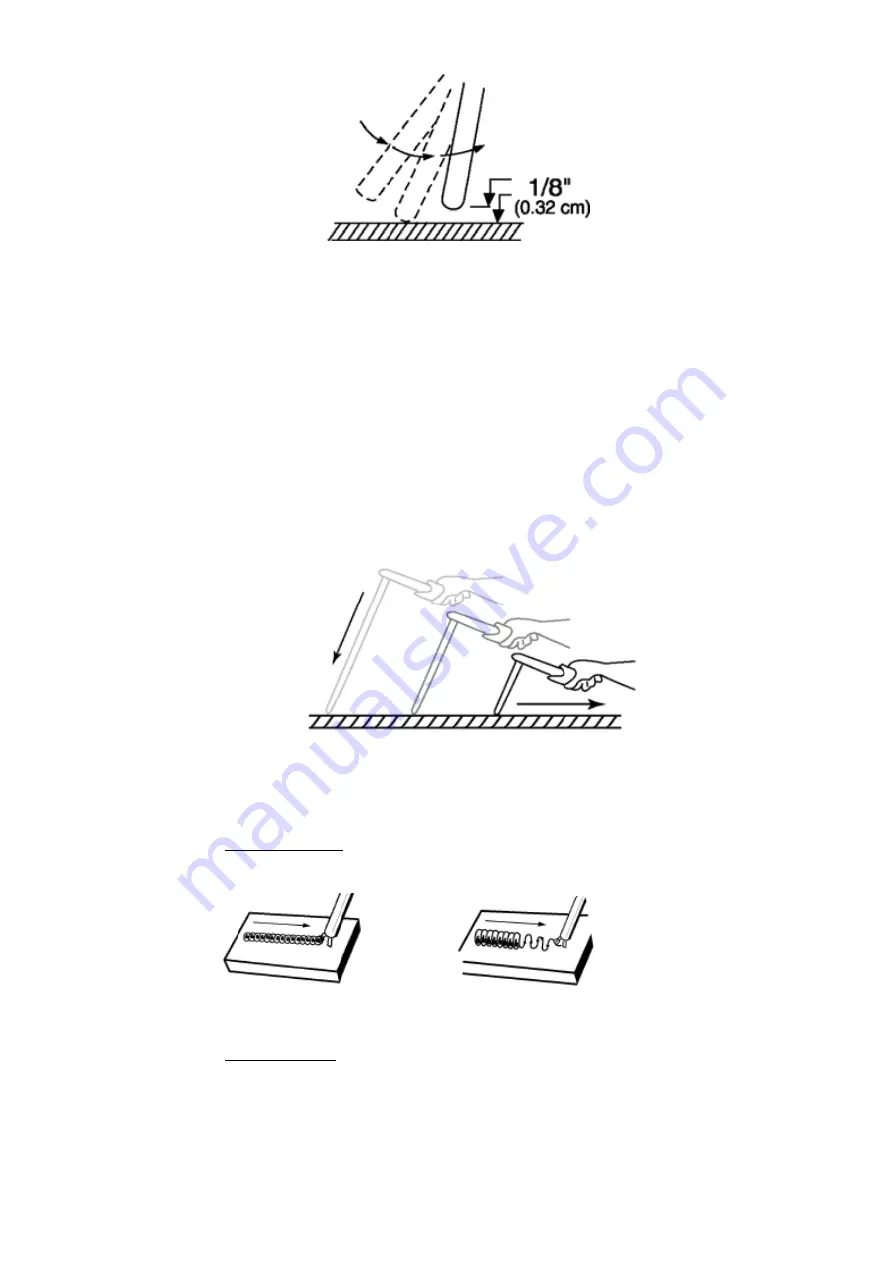

It is important that the gap be maintained during the welding process and it shouldn’t

be too wide or too narrow. If it’s too narrow, the rod will stick to the work piece. If it’s

too wide, the arc will be extinguished. It needs much practice to maintain the gap.

Beginners may get sticker or arc extinguishing. When the rod is stuck to the work

piece, gently rock it back and forth to separate them. If not, a short circuit will occur

and it will break the welder. A good arc is accompanied by a crisp, cracking sound

(eggs frying). To lay a weld bead, only two movements are required: downward (as

the electrode is consumed) and in the direction the weld is to be laid, as in the

following figure:

6.3

Types of weld bead

The following paragraphs discuss the most commonly used arc welding beads.

The stringer bead

is formed by traveling with the electrode in a straight line while

keeping the electrode centered over the weld joint.

The weave bead is used when you want to deposit metal over a wider space than

would be possible with a stringer bead. It is made by weaving from side to side while

moving with the electrode. It is best to hesitate momentarily at each side before

weaving back the other way.

Stringer Bead

Weave Bead