4

317961000

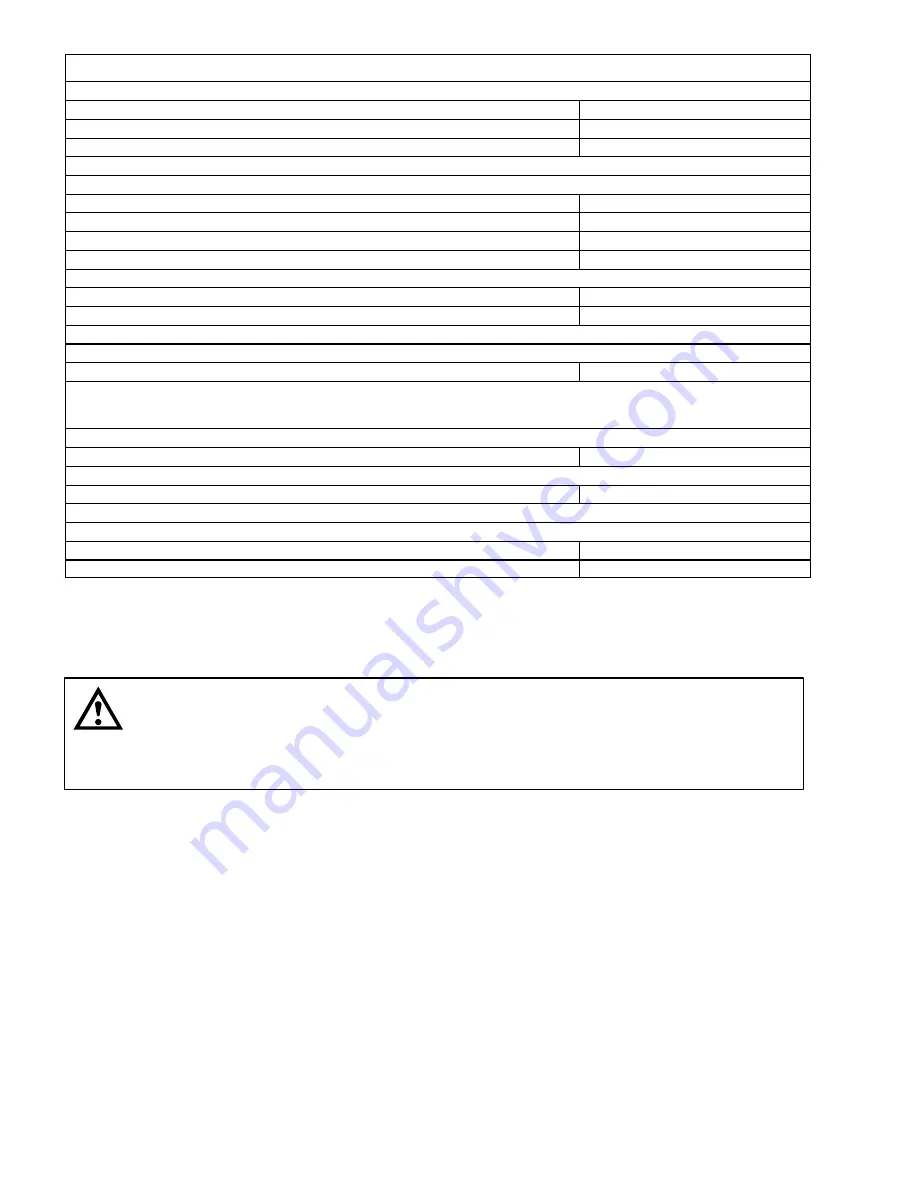

Table 1. Design Data (cont’d)

Overall Dimensions:

Width

13-inches

Height

27-inches

Depth

22-inches

Weights:

Shipping (one carton)

Dry Weight (approximate)

83 pounds

Ice Bank Weight (approximate)

18 pounds

Drop-in Refrigeration Assembly

42 pounds

Water Bath Capacity

7 gallons

(no ice bank)

Dispensing Rate:

Three 12-oz. Drinks/Min. @ 40

°

F or below

(approx)*100

NOTE: *Number of 12-oz. drinks dispensed 40

°

F or below @ 75

°

F syrup and water inlet temperature

and 75

°

F ambient.

Refrigerant Requirement

See Unit Nameplate

Ambient Operating Temperature

40

°

F to 100

°

F

Electrical Requirements:

Operating Voltage

See Unit Nameplate

Current Draw

See Unit Nameplate

THEORY OF OPERATION

(see Figure 2)

WARNING: CO

2

displaces oxygen. Strict attention must be observed in the prevention of

CO

2

(carbon dioxide) gas leaks in the entire CO

2

and soft drink system. If a CO

2

gas leak is

suspected, particularly in a small area, immediately ventilate the contaminated area before

attempting to repair the leak. Personnel exposed to high concentration of CO

2

gas will experience

tremors which are followed rapidly by loss of consciousness and suffocation.

NOTE: The Unit was set up at the factory to dispense a still (non-carbonated) drink from No. 3

dispensing valve and carbonated drinks from remaining valves. No. 3 dispensing valve may be

converted to also dispense a carbonated drink. Refer to TABLE OF CONTENTS for conversion

instructions.

A CO

2

cylinder delivers carbon dioxide (CO

2

) gas through adjustable CO

2

regulators to syrup tanks and to the

remote carbonator. Plain water enters remote carbonator tank and is carbonated by regulated CO

2

pressure

also entering tank. When all dispensing valves except No. 3 are opened, CO

2

pressure exerted upon contents

of syrup tanks pushes syrup from tanks, through Unit syrup cooling coils, to dispensing valves. Carbonated

water is pushed from remote carbonator by CO

2

pressure and is pushed through Unit carbonated water cooling

coils to dispensing valves. Syrup and carbonated water meet simultaneously at dispensing valves resulting in

carbonated drinks being dispensed. A still (non-carbonated) drink is dispensed from No. 3 dispensing valve in

same manner as carbonated drinks except plain water is substituted for carbonated water.

When Unit power cord is plugged into electrical outlet and POWER switch is placed in ‘‘ON’’ position,

compressor, condenser fan motor, and agitator motor will start and begin forming an ice bank in the water tank.

When full ice bank has been formed, compressor and condenser fan motor will stop but agitator motor will

continue to operate circulating ice water in the water tank. Water tank ice bank control will cycle compressor and

condenser fan motors on and off as required to maintain a full ice bank.

Summary of Contents for SPIRIT

Page 6: ......

Page 7: ...2 317961000 THIS PAGE LEFT BLANK INTENTIONALLY ...

Page 11: ...6 317961000 THIS PAGE LEFT BLANK INTENTIONALLY ...

Page 17: ...12 317961000 THIS PAGE LEFT BLANK INTENTIONALLY ...

Page 21: ...16 317961000 THIS PAGE LEFT BLANK INTENTIONALLY ...

Page 40: ...35 317961000 THIS PAGE LEFT BLANK INTENTIONALLY ...