34

Artiglio Master Code

User Manual

5.2. PRElIMINARY CHECks

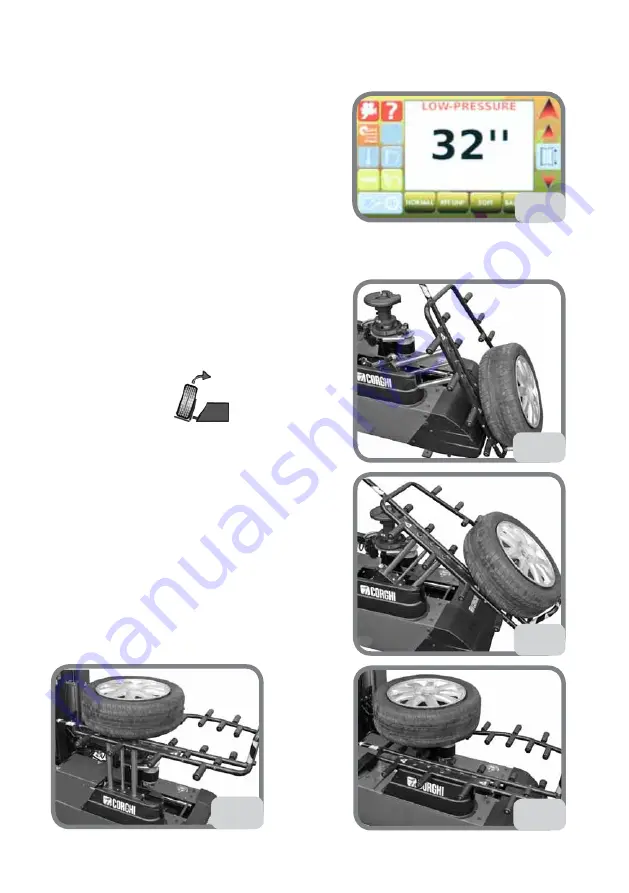

Check that there is a pressure of at least 8 bar on

the Filter Regulator pressure gauge.

If the pressure is lower, the operation of some

automatic procedures is not guaranteed and the

display will show LOW-PRESSURE Fig. 25.

However, it is still possible to operate in manual

mode.

After the correct pressure has been restored, the

machine will function properly.

Check that the machine has been adequately connected to the power mains.

5.3. lOADING AND ClAMPING THE

WHEEl

- Load the wheel onto the wheel lifter (Fig. 26a).

- Operate the Lever

and lift the wheel

until it is positioned on the turntable (see Figs. 26b,

26c, 26d) making sure the movable pin is inserted

in one of the fastening bolt holes (see Fig. 26e).

- fit the cone on the handle, using the extension

as necessary (see

the diagram for using cen-

tring and clamping accessories per type of rim

in this manual).

- Insert the handle (

a

) in the central hole and turn

clockwise until it stops (Fig. 26f).

26b

26c

26d

26a

25

Summary of Contents for Artiglio Master Code

Page 13: ...Artiglio Master Code User Manual 13 UK 1 5 6 7 8 9 11 12 14 15 16 7 18 12...

Page 114: ...114 Artiglio Master Code User Manual M13 M14 M11 M7 M2 M9 A M16 STANDARD RIM...

Page 115: ...Artiglio Master Code User Manual 115 UK M6 M5 M11 M7 M9 B M16 DROPPED CENTRE HOLE RIM...

Page 116: ...116 Artiglio Master Code User Manual C M11 M2 REVERSED RIM...

Page 117: ...Artiglio Master Code User Manual 117 UK D M10 M2 M15 M9 PICK UP RIM...

Page 118: ...118 Artiglio Master Code User Manual E CLOSED CENTRE RIM...

Page 119: ...Artiglio Master Code User Manual 119 UK F OPEN CENTRE RIM with delicate hole edges...

Page 120: ...Notes 120...

Page 123: ...Artiglio Master Code User Manual 123 UK 81...

Page 124: ...124 Artiglio Master Code User Manual...

Page 125: ...Artiglio Master Code User Manual 125 UK 82...

Page 126: ...126 Artiglio Master Code User Manual 83...

Page 127: ...Artiglio Master Code User Manual 127 UK 84...

Page 128: ...128 Artiglio Master Code User Manual 85...

Page 129: ...Artiglio Master Code User Manual 129 UK 86...

Page 134: ...Notes 134...

Page 135: ...Notes 135...