8

SQN IO&M

B51141-004

Bearing Replacement

The fan bearings are pillow block ball bearings.

1. Loosen screws on bearing cover.

2. Push bearing cover toward the wheel. As the bearing

cover moves toward the wheel it will slide down to re-

veal the bearings and shaft.

3. Remove the old bearing.

4. Remove any burrs from the shaft by sanding.

5. Slide new bearings onto the shaft to the desired lo-

cation and loosely mount bearings onto the bearing

support. Bearing bolts and setscrews should be loose

enough to allow shaft positioning.

6. Correctly position the wheel and tighten the bearing

bolts securely to the bearing support.

7. Align setscrews bearing to bearing and secure tightly

to the shaft.

NOTICE! Never tighten both pairs of setscrews before

securing bearing mounting bolts. This may damage

the shaft.

8. Inspect the wheel position again. If necessary, read-

just by loosening the bearing bolts and setscrews and

repeat from step 5.

Wheel Replacement

1.

Drill two 1/4” diameter holes, 180° apart centered ap

-

proximately between the shaft and the outside diam-

eter of the hub, 3/8” to 1/2” in depth.

2.

Tap 1/4” holes to 5/16” thread with a 5/16” hole tap. Do

not drill or tap greater than recommended.

3. Screw the puller arms to the full depth of the threads

into the tapped holes. Align center of the puller with

the center of the shaft. Ensure all setscrews in the

hub, normally two, are fully removed.

4. Slowly remove wheel from the shaft.

Recommended Puller

Lisle No. 45000 Sterling Wheel Puller. This puller is

available at most automotive parts retail outlets.

Wheel Replacement Components

Drilled hole placement.

Wheel puller.

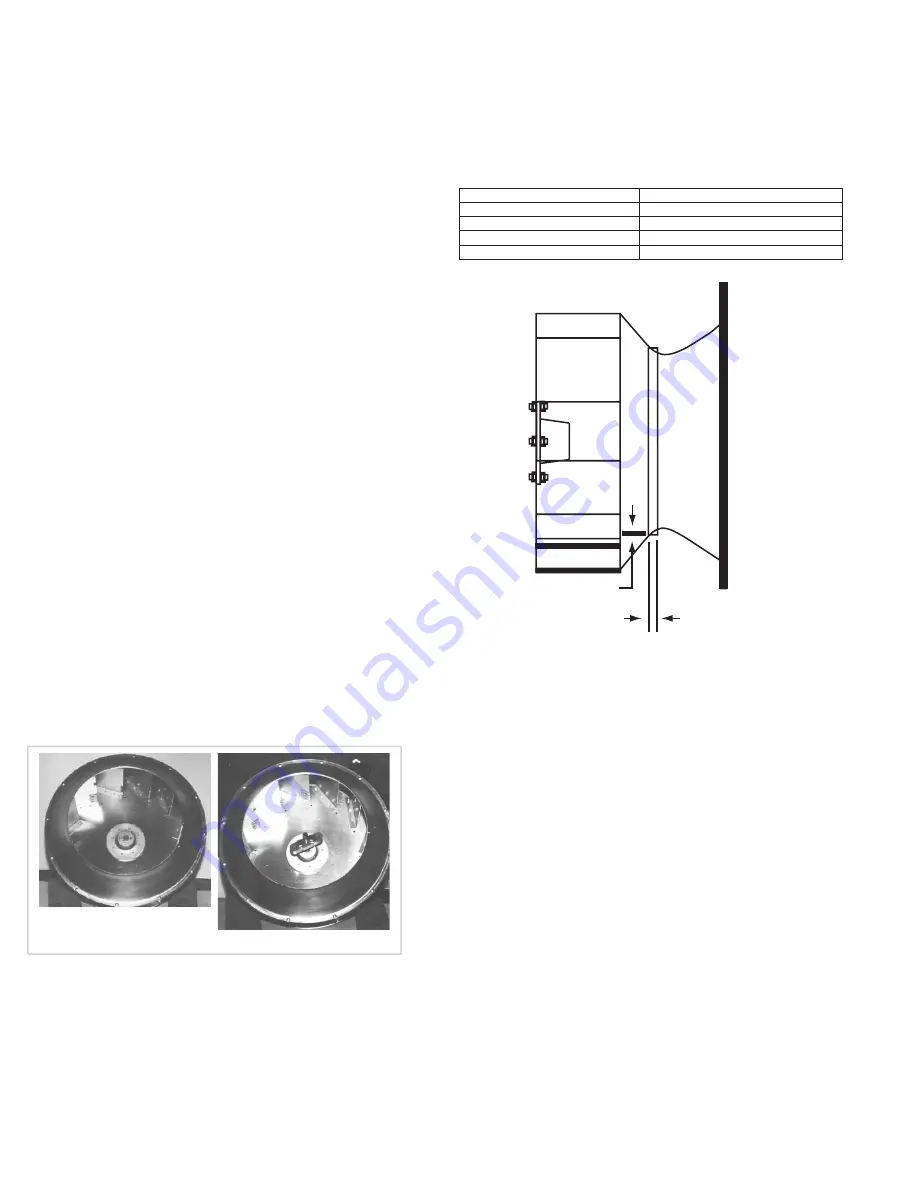

Wheel-to-Inlet Clearance

The correct wheel-to-inlet clearance is critical to prop-

er fan performance. This clearance should be verified be

-

fore initial start-up since rough handling during shipment

could cause a shift in fan components. Refer to

Wheel/

Inlet

drawing for correct overlap.

Adjust the overlap by loosening the wheel hub and mov-

ing the wheel along the shaft to obtain the correct value.

A uniform radial gap (space between the edge of the

cone and the edge of the inlet) is obtained by loosening the

inlet cone bolts and repositioning the inlet cone.

Wheel/Inlet Overlap

Size

Maximum Overlap

100- 195

5/8”

210-270

3/4”

300-445

1”

490 730

1-1/4”

Radial Clearance

Overlap