6

HMD IO&M

B51242-002

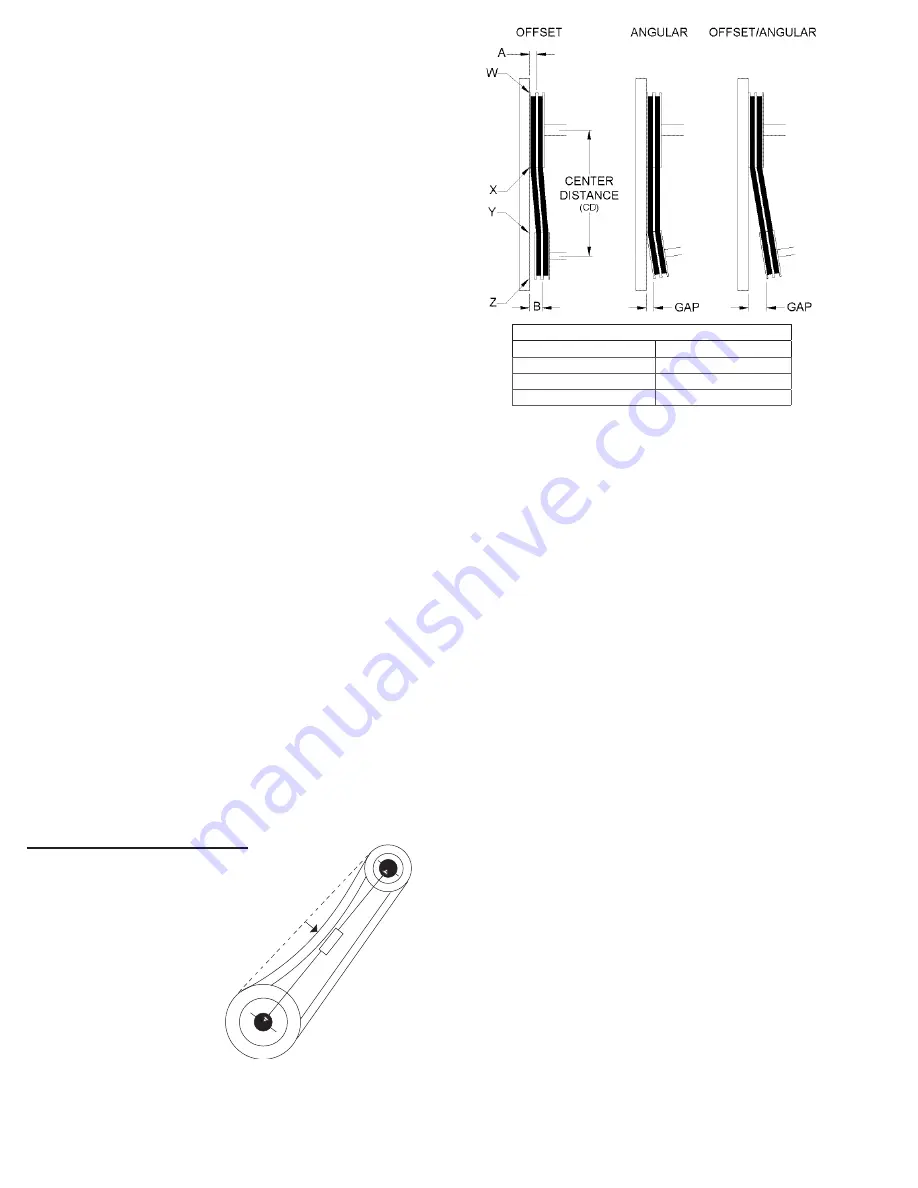

Tolerance

Center Distance

Maximum Gap

Up thru 12”

1/16”

12” up through 48

1/8”

Over 48”

1/4”

NOTICE! Premature or frequent belt failures can

be caused by improper belt tension, or misaligned

sheaves. Abnormally high belt tension or drive mis-

alignment will cause excessive bearing loads and

may result in failure of the fan and/or motor bearings.

Abnormally low belt tension will cause squealing on

start-up, excessive belt flutter, slippage, and overheat

-

ed sheaves.

1. V-belt drives must be checked on a regular basis for

wear, tension, alignment, and dirt accumulation.

2.

Check the tension by measuring the deflection in the

belt as shown here.

3. Check the alignment by using a straight edge across

both sheaves. The drawings below show where to

measure the allowable gap for the drive alignment

tolerance. All contact points (indicated by WXYZ) are

to have a gap less than the tolerance shown in the

table. When the pulleys are not the same width, the

allowable gap must be adjusted by half of the differ

-

ence in width.

Snow Accumulation

Clear snow away from roof mounted units. Keep the

snow clear of the intake and access doors.

Motors

Motor maintenance is generally limited to cleaning and

lubrication (where applicable). Cleaning should be limited

to exterior surfaces only. Removing dust and grease build-

up on the motor assures proper motor cooling.

Motors supplied with grease fittings should be greased

in accordance with the manufacturer’s recommendations.

Greasing motors is only intended when fittings are provid

-

ed. Many motors are permanently lubricated, requiring no

additional lubrication.

NOTICE! Do not allow water or solvents to enter the

motor or bearings. Motors and bearings should never

be sprayed with steam, water or solvents.

3. With all access panels in place, the fan running and

discharging 70ºF (21ºC) air, connect a U-Tube ma-

nometer to the outer sensing probes and measure

the static pressure across the burner. The proper

static pressure should be (check

CFM / Static Pres-

sure chart

on page tk). If needed, evenly adjust the

baffles, keeping the burner centered in the opening

until the required pressure is obtained. The pressure

drop was set at the factory and may not need adjust-

ment. When required pressure is obtained, be sure

to reconnect the outer sensing probes. This process

may need to be repeated until the proper pressure is

achieved. This adjustment will change the air quanti-

ty delivered by the unit and therefore the air quantity

delivered should be rechecked. Refer to the

Blower

Start-Up

section.

• To increase static pressure decrease the opening.

• To decrease static pressure increase the opening.

4. Monitor the unit’s actual temperature rise by placing

a thermocouple in the unit’s inlet and a second in the

discharge, three duct diameters downstream of the

burner. Send the unit to maximum flame by chang

-

ing the rotation of the motor pack from left to right.

Use a screw driver on top of modular gas valve.

While monitoring the unit’s temperature rise, set the

maximum firing rate by adjusting the regulator until

the designed temperature rise is achieved. After set-

ting the maximum firing rate, reconnect the wire to

the amplifier. Do not set the burner maximum firing

rate based on gas pressure. It should be set based

on the unit’s designed temperature rise shown on

the label. Setting the maximum firing rate during

mild weather conditions may cause the high limit to

trip out during extreme conditions requiring manual

resetting. Gas trains are equipped with a combined

regulator valve. Clockwise rotation increases the

temperature rise; counterclockwise rotation de-

creases the temperature rise. The minimum setting

for the maximum firing rate may be higher than re

-

quired. This is acceptable, the burner will modulate

as needed. To convert from Natural Gas to LP or

vice versa follow the instructions associated with the

high fire gas valve.

5. Set the operating temperature.

Maintenance - All year

V-Belt Drives

NOTICE! Do not pry belts on or off

the sheave. Loosen belt tension

until belts can be removed by

simply lifting the belts off

the sheaves. When replac-

ing V-belts on multiple

groove drives, all belts

should be changed to

provide uniform drive

loading. Do not install

new belts on worn

sheaves. If the sheaves have grooves worn in them,

they must be replaced before new belts are installed.

1 foot

1/4 inch