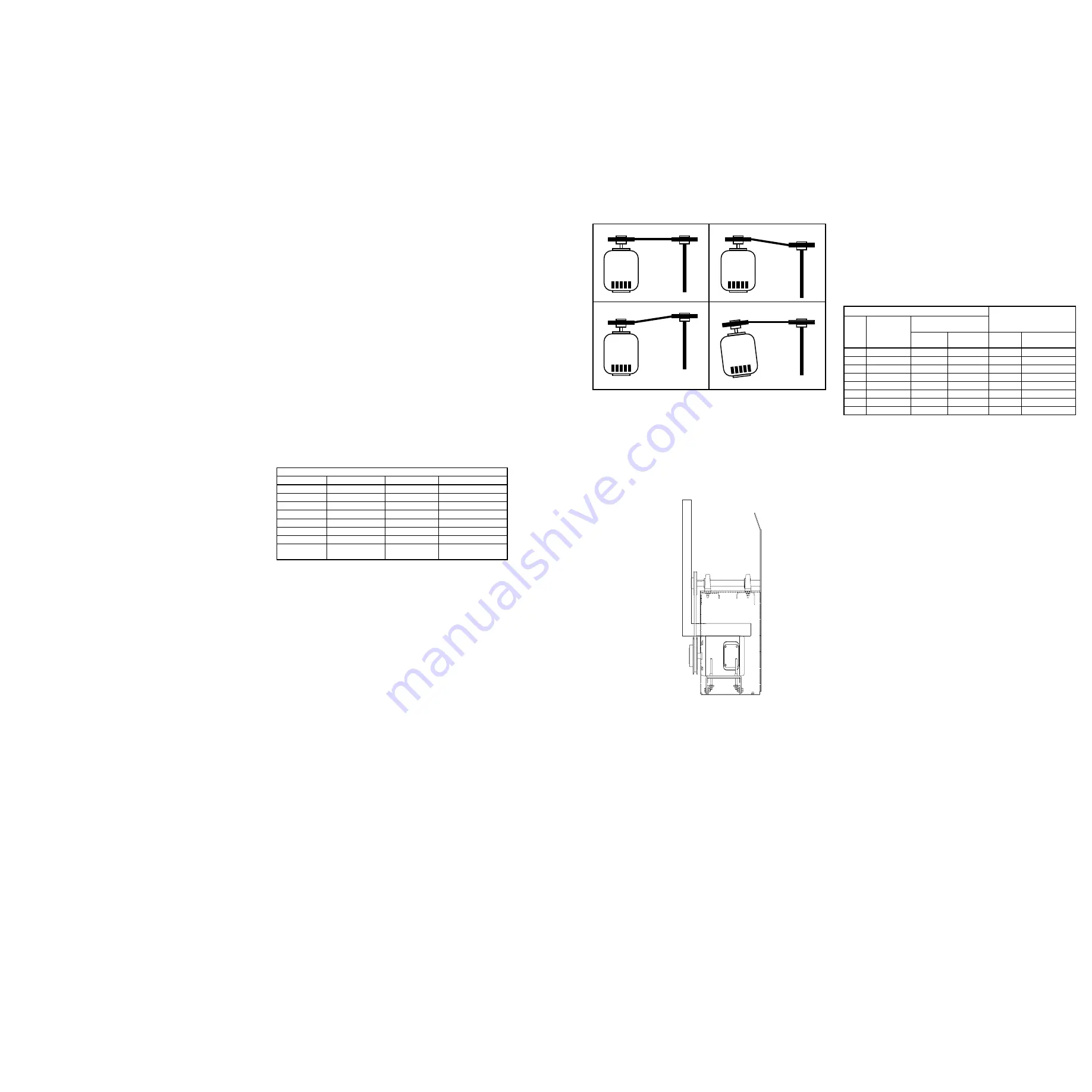

Pulley Alignment

Pulley alignment is adjusted by loosening the motor pul-

ley setscrew and by moving the motor pulley on the motor

shaft or by moving the entire motor along the motor mount-

ing bracket.

Figure 4

illustrates correct and incorrect pulley alignment.

A recommended method of inspecting the pulley alignment

with a square is shown below in

Figure 5

.

Final Installation Steps

a. Inspect fasteners and setscrews, particularly fan

mounting and bearing fasteners, and tighten according

to the recommended torque shown in the table

Rec-

ommended Torque for Setscrews/Bolts

.

b. Inspect for correct voltage with voltmeter.

c. Ensure all accessories are installed.

Operation

Pre-Start Checks

a. Lock out all the primary and secondary power sources.

b. Ensure fasteners and setscrews, particularly those

used for mounting the fan, are tightened.

c. Inspect belt tension and pulley alignment.

Correct

Incorrect

Incorrect

Incorrect

Figure 4

d. Inspect motor wiring.

e. Ensure belt touches only the pulleys.

f. Ensure fan and ductwork are clean and free of debris.

g. Inspect wheel-to-inlet clearance. The correct wheel-to-

inlet clearance is critical to proper fan performance.

h. Close and secure all access doors.

i. Restore power to the fan.

Start Up

Turn the fan on. In variable speed units, set the fan to its

lowest speed and inspect for the following:

• Direction of rotation.

• Excessive vibration.

• Unusual noise.

• Bearing noise.

• Improper belt alignment or tension (listen for squeal-

ing).

• Improper motor amperage or voltage.

If a problem is discovered, immediately shut the fan

off. Lock out all electrical power and check for the

cause of the trouble.

See

Troubleshooting

.

Inspection

Inspection of the fan should be conducted at the

fi

rst

30

minute, 8 hour

and

24 hour

intervals of satisfactory opera-

tion. During the inspections, stop the fan and inspect as per

the

Conditions Chart

.

30 Minute Interval

Inspect bolts, setscrews, and motor mounting bolts.

Adjust and tighten as necessary.

8 Hour Interval

Inspect belt alignment and tension. Adjust and tighten as

necessary.

24 Hour Interval

Inspect belt tension, bolts, setscrews, and motor mount-

ing bolts. Adjust and tighten as necessary.

Recommended Torque for Setscrews/Bolts (IN/LB.)

Setscrews

Hold Down Bolts

Size

Key Hex

Across Flats

Recommended Torque

Inch-lbs.

Min.

Max.

Size

Wrench Torque

(inch-lbs)

No.10

3/32”

28

33

3/8”-16

240

1/4”

1/8”

66

80

1/2”-13

600

5/16”

5/32”

126

156

5/8”-11

1200

3/8”

3/16”

228

275

3/4”-10

2100

7/16”

7/32”

348

384

7/8”- 9

2040

1/2”

1/4”

504

600

1”- 8

3000

5/8”

5/16”

1104

1200

1-1/8” - 7

4200

3/4”

3/8”

1440

1800

1-1/4” - 7

6000

3

6

Conditions Chart

RPM

Temperature

Fan Status

Greasing Interval

100

Up to 120

˚

F

Clean

6 to 12 months

500

Up to 150

˚

F

Clean

2 to 6 months

1000

Up to 210

˚

F

Clean

2 weeks to 2 months

1500 Over

210

˚

F

Clean

Weekly

Any Speed

Up to 150

˚

F

Dirty

1 week to 1 month

Any Speed

Over 150

˚

F

Dirty

Daily to 2 weeks

Any Speed

Any Temperature

Very Dirty

Daily to 2 weeks

Any Speed

Any Temperature

Extreme

Conditions

Daily to 2 weeks

Current Switch Set-UP

General Notes:

1. The current sensor is preset at factory.

2. The sensor is designed to shut down the broiler in the

event that the motor current drops below normal. This

will re

fl

ect a problem such as a broken belt.

3. Current sensor shall be enclosed in a (UL Listed for

Outdoor Use) conduit box. Wire shall be ran through

(UL Listed for Outdoor Use) conduit and connectors.

Notes for Current Sensor:

1. Typical operation: Line voltage applied continuously.

After seven seconds of fault, relay trips. If current is

below set point, red LED will light. Current window is

adjustable between 1-10 amps. Adjustments are inde-

pendent.

2. Typical setup: Adjust undercurrent pot to minimum,

clockwise is maximum. Apply current. Once current has

stabalized, adjust undercurrent pot by turning up until red

LED lights. Then turn down within seven seconds until red

light turns off. If a light remains on for more than ten sec-

onds, disconnect supply voltage to reset. Fault window var-

ies by how far the pots are adjusted. Now if a fault occurs

for greater than seven seconds, the relay will trip until sup-

ply voltage is removed.

Maintenance

Establish a schedule for inspecting all parts of the fan.

The frequency of inspection depends on the operating con-

ditions and location of the fan.

Inspect fans exhausting corrosive or contaminated air

within the

fi

rst month of operation. Fans exhausting contam-

inated air (airborne abrasives) should be inspected every

three months.

Regular inspections are recommended for fans exhaust-

ing non-contaminated air.

It is recommended the following inspection be conducted

twice per year.

• Inspect bolts and setscrews for tightness. Tighten as

necessary. Worn setscrews should be replaced immedi-

ately.

• Inspect belt wear and alignment. Replace worn belts

with new belts and adjust alignment as needed. See

Belt and Pulley Installation

, page 3.

• Bearings should be inspected as recommended in the

Conditions Chart

.

• Inspect springs and rubber isolators for deterioration

and replace as needed.

• Inspect for cleanliness. Clean exterior surfaces only.

Removing dust and grease on motor housing assures

proper motor cooling. Removing dirt from the wheel and

housing prevent imbalance and damage.

Lubricants

Loren Cook Company uses petroleum lubricant in a lithium

base. Other types of grease should not be used unless the

bearings and lines have been

fl

ushed clean. If another type

of grease is used, it should be a lithium-based grease con-

forming to NLGI grade 2 consistency.

A NLGI grade 2 grease is a light viscosity, low-torque,

rust-inhibiting lubricant that is water resistant. Its tempera-

ture range is from -30

°

F to +200

°

F and capable of intermit-

tent highs of +250

°

F.

Motor Bearings

Motor bearings are pre-lubricated and sealed. Under nor-

mal conditions they will not require further maintenance for

a period of ten years. However, it is advisable to have your

maintenance department remove and disassemble the

motor, and lubricate the bearings after three years of opera-

tion in excessive heat and or in a contaminated airstream

consisting of airborne abrasives.

Fan Bearings

Greasable fan bearings are lubricated through a grease

fi

tting on the bearing and should be lubricated by the sched-

ule,

Conditions Chart

.

For best results, lubricate the bearing while the fan is in

operation. Pump grease in slowly until a slight bead forms

around the bearing seals. Excessive grease can burst seals

thus reducing bearing life.

In the event the bearing cannot be seen, use no more

than three injections with a hand-operated grease gun.

Motor Services

Should the motor prove defective within a one-year

period, contact your local Loren Cook representative or

your nearest authorized electric motor service representa-

tive.

Figure 5

Figure 5