NR9000-TC REMOTE CONTROL

The remote control is infrared type with a graphic display and pro-

gramming keyboard.

For a correct work, it is necessary a visual contact with the receiver

fitted on board of the unit to be controlled.

It is necessary that the infrared control is pointed towards the receiv

-

er and that the distance between infrared control and receiver is

max 5/6 meters.

The correct delivery of the information to the receiver module is sig

-

nalled with an alternating blinking of the GREEN and YELLOW LED

placed on the receiver module.

Setting will be sent to the receiver module with a single message in

the moment in which you press the button “OFF” or “ON/SEND”.

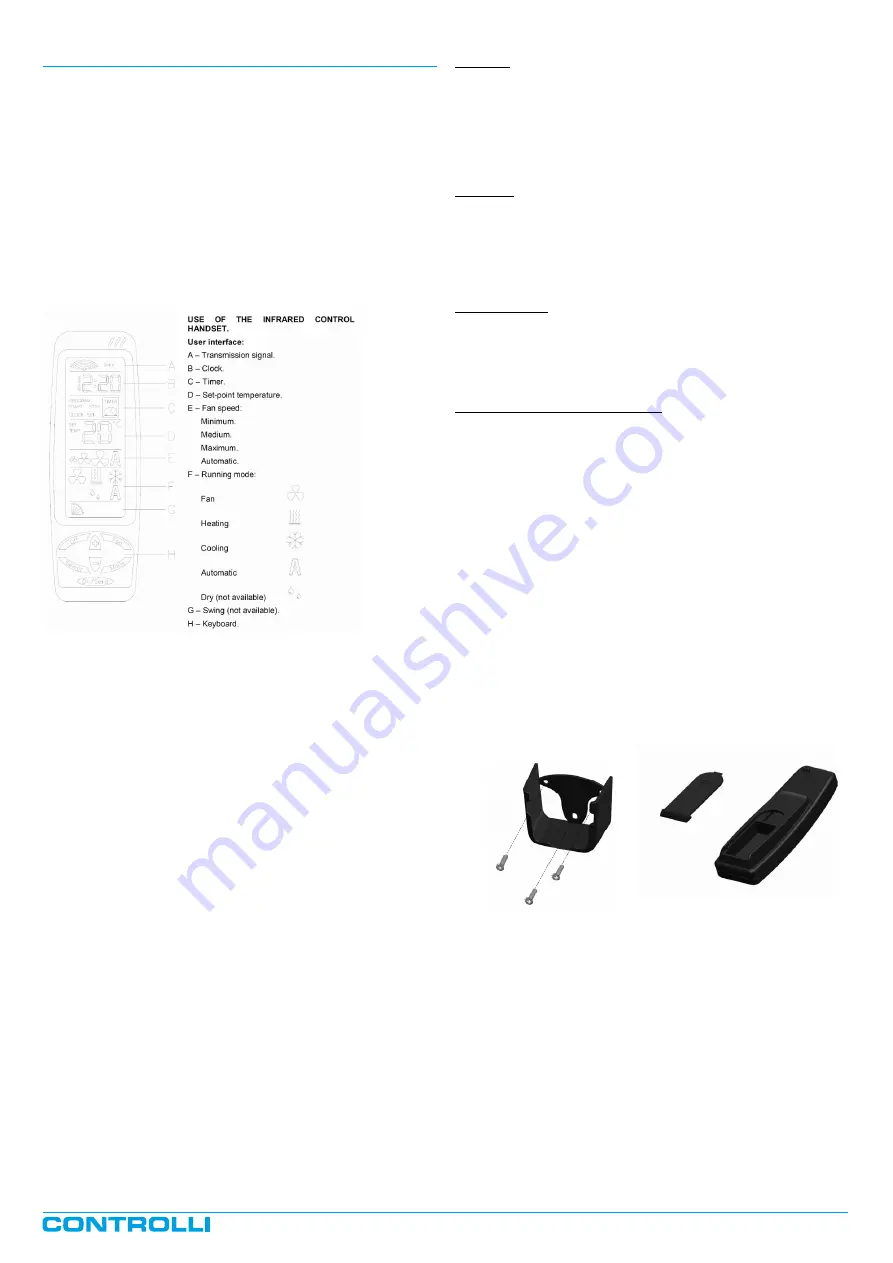

Use of the infrared handset

Description of the controls

ON/SEND

Switches on the unit and/or update the information.

MODE

Press button MODE to change between only Ventilation, Heating,

Cooling and Automatic Work.

Press ON/SEND button to send information to the unit.

Dry function is not available.

FAN

Press FAN button to change between Min, Med, Max speed and

Auto (A) (automatic speed).

Press ON/SEND button to send information to the unit.

Description of the function visualized on the display

SET POINT TEMPERATURE

In order to set the desired temperature inside the room (set-point

temperature) in order to increase it press button (+), in order to de-

crease it press button (-) until the desired temperature.

Press ON/SEND button to send information to the unit.

SWING mode

(not available)

CLOCK SET UP

Press SELECT button, the word CLOCK SET will light.

Press (+) or (-) button, the word CLOCK SET will become fix and the

hours value will start lighting.

Use (+) button to increase or (-) to decrease the hours.

Press SELECT button, the minutes value will light.

Use (+) button to increase or (-) to decrease minutes.

Press SELECT button to stop the set up.

Press ON/SEND button to send information to the unit.

TIMER PROGRAM

Start time:

Press SELECT button twice, the word PROGRAM and the word START

(lighting) will be displayed.

Press (+) or (-) button, the word START will become fix and the hours

value will start lighting.

Use (+) button to increase or (-) to decrease the hours.

Press SELECT button, the minutes value will light.

Use (+) button to increase or (-) to decrease minutes.

Stop time:

Press SELECT button, the word STOP will light on the display.

Press (+) or (-) button, the word STOP will become fix and the hours

value will start lighting.

Use (+) button to increase or (-) to decrease the hours.

Press SELECT button, the minutes value will light.

Use (+) button to increase or (-) to decrease the minutes.

ON or OFF Timer:

Press SELECT button, the TIMER icon will start lighting.

Press (+) button to start the timer (dark icon) or (-) button to de-acti

-

vate it (light icon).

Press SELECT button to store the information.

Press ON/SEND button to send information to the unit.

General information on timer mode:

Once set up the timer program, it will be repeated day by day until

it will be cancelled (timer OFF).

It is possible to by-pass manually the set automatic program by press-

ing ON/SEND button to switch on the unit or pressing OFF button to

switch off the unit.

The manual mode will be ON until the next automatic mode of the

program.

NR9000-TC infrared remote control mounting instructions

NR9000-TC infrared remote control is supplied together with a sup-

port for wall mounting and batteries. To fix the support to the wall use

screws of correct diameter and length (not supplied).

1.

Open the back cover and slide it outward;

2.

insert the 2 alkaline batteries (size AAA 1,5V) according to po

-

larity;

3. the display will power on;

4.

close the cover again.

NOTE: in case of batteries replacement, after removal of the exhaust

-

ed ones, wait for 10 minutes before installing the new ones.

1

st

Issue rev. c

12/2015

DBL408e

Page 17