17

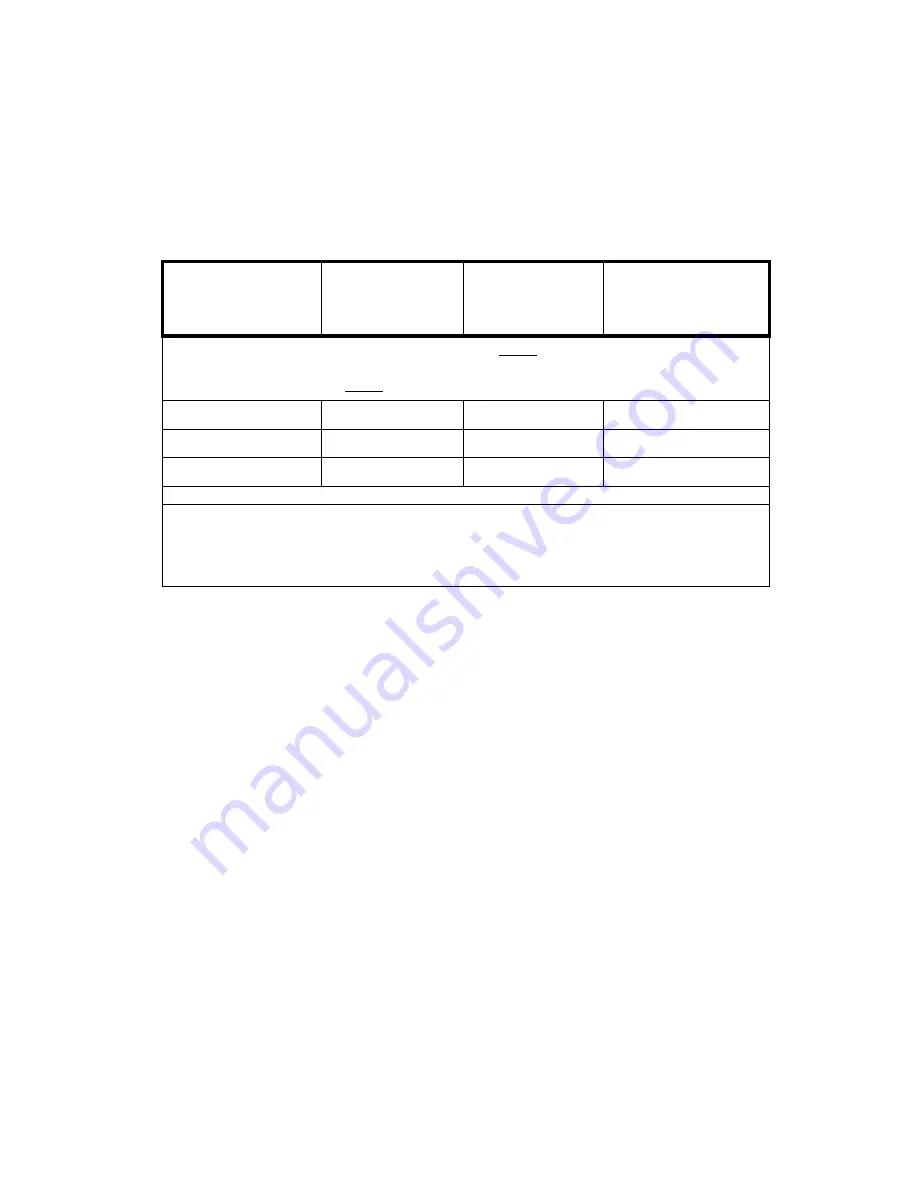

Minimum recommended sterilization exposure times are as follows:

Table 1: Sterilization Parameters

Sterilization Type

Minimum

Temperature

Recommended

Minimum

Exposure Time

Dry Time

Sterilization Parameters for sterilizing the PowerPro Pneumatic Handpieces

(PRO6150, PRO6175, PRO6185), Associated Attachments, and Hose, with or without the

PowerPro PRO5090 Sterilization Case

Steam Pre-vacuum

270°F (132°C)

4 minutes

8 minutes minimum

Steam Gravity

270°F (132°C)

10 minutes

8 minutes minimum

Steam Gravity

250°F (121°C)

40 minutes

8 minutes minimum

CAUTION: The recommended dry cycle must be run on all handpieces and attachments

every time the product is sterilized. Failure to use a dry cycle on the products may lead to

reduced product performance or premature product failure. Operation of a handpiece that is

not completely cool and dry may decrease performance and/or reliability.