Setting Up Your Printer

13

P

P

a

a

p

p

e

e

r

r

C

C

h

h

u

u

t

t

e

e

I

I

n

n

s

s

t

t

a

a

l

l

l

l

a

a

t

t

i

i

o

o

n

n

(

(

4

4

0

0

5

5

1

1

/

/

4

4

0

0

5

5

6

6

p

p

l

l

u

u

s

s

m

m

o

o

d

d

e

e

l

l

s

s

o

o

n

n

l

l

y

y

)

)

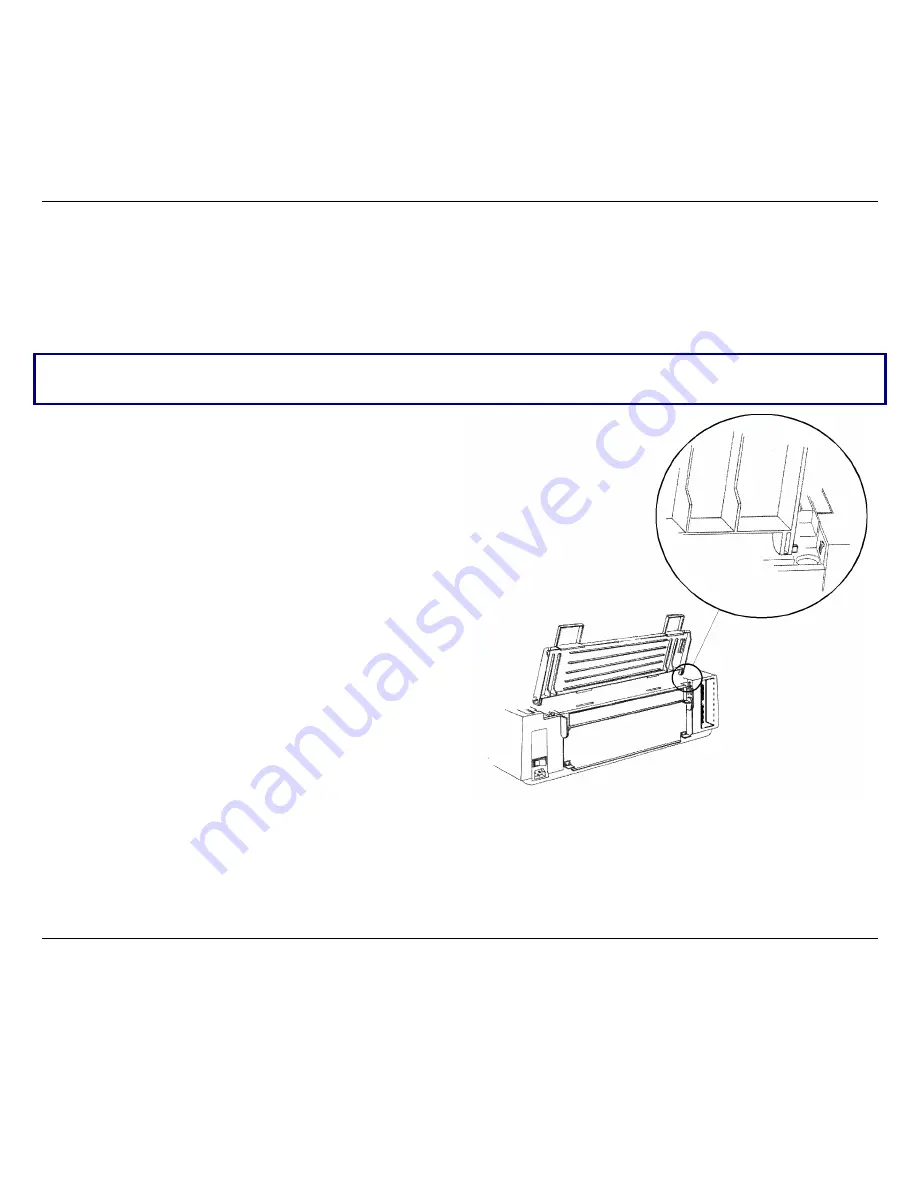

The paper chute is provided with the 4051plus and 4056 plus printers. To install the paper chute

in the printer follow this sequence:

To insert the paper chute correctly, make sure that you are in front of the printer and that you hold

the paper chute in the front position.

1. Insert the hook on the left side of the paper

chute in the groove situated near the paper

entry slot.

The figure shows the back of the printer and

the paper chute in the back position for a

good view of the hook and groove. For this

reason, you will see the left side of the paper

chute shown on the right.