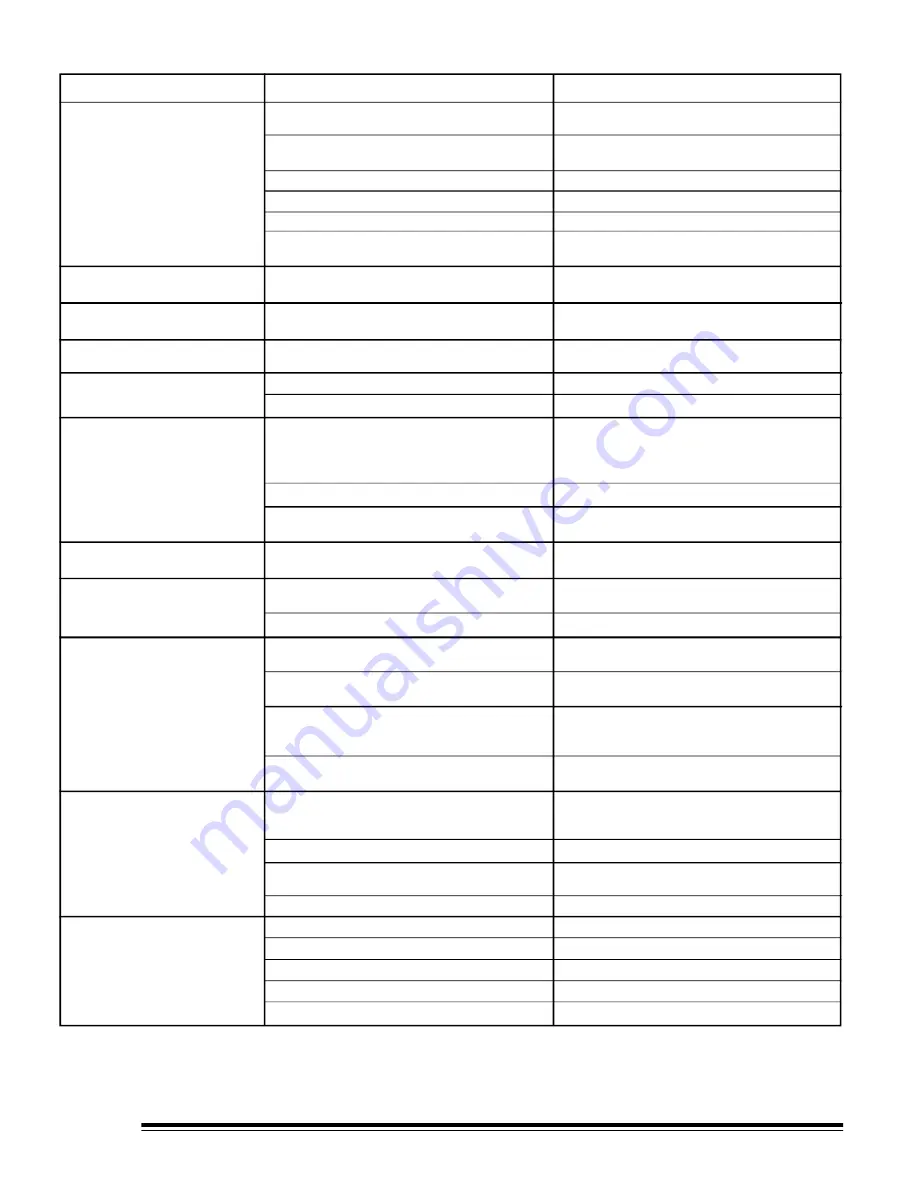

14

Lack of high frequency at tungsten

electrode, difficulty in starting and

arc.

5-2 TROUBLESHOOTING.

Tungsten electrode oxidizing and

not remaining bright after conclusion

of weld.

Unit provides only maximum or

minimum weld output.

Weld output always above or

always below set value.

Electronic board PC1.

Erratic weld output

No control of weld output.

No weld output, fan runs.

No weld output, unit completely

inoperative

TROUBLE

REMEDY

CAUSE

Gas shutting off too quickly after end of weld.

Loose gas fittings on regulator or gas line. This

will siphon oxygen into the weld zone.

Insuficient gas flow.

Drafts blowing gas shield away from tungten.

Contaminated tungten.

High frequency switch in OFF position.

Increase time settings of post-flow time control (See

figure 4-11).

Check and tighten all gas fittings.

Increase gas flow setting.

Shield weld zone from drafts.

Prepare tungsten as instructed in section 8.2.

Place HIGH FRECUENCY in START or CONTINUOUS

position.

Consult your dealer or Service Center to review unit.

Electronic board PC1.

Consult your dealer or Service Center to review unit.

Electronic board PC1.

Consult your dealer or Service Center to review unit.

AC Balance control R3.

Circuit Board PC1.

Amperage control switch S5 position.

Amperage adjustment control R1.

Check and replace R3.

Place S5 in PANEL position, if no remote control is

begin used. Place S5 in REMOTE position and be sure

remote control Is connected to REMOTE 14 receptacle

RC2 (See Section 3-5 & Figure 4-6).

Check And Replace R3.

Electronic board PC1.

Consult your dealer or Service Center to review unit.

No AC BALANCE control

No HIGH FREQUENCY, No gas flow,

and no spot time (If applicable)

Circuit Breaker CB1.

Check and reset CB1 if necessary.

Improperly prepared tugsten.

Wandering Arc - Poor Control Of

Direction Of Arc

Use of tungsten considerably larger

than recommended.

Prepare tungsten as instructed in section 8-2.

Use proper size tungsten (See Table 8-1).

Use of tungsten larger than recomended for

welding amperage.

Consult your dealer or Service Center to review unit.

Disipation of high frequency from SMAW electrode

holder lead.

Be sure to disconnect SMAW electrode cable from

weld output terminal when GTAW welding

Improper spark gap.

Weld cable leakage.

Check spark gaps and readjust if necessary (See

section 5.5)

Check cables and torch for cracked or deteriorated

insulation or bad connections. Repair or replace

necessary parts.

Consult your dealer or Service Center to review unit.

Output contactor switch S3 position

Remote control device.

Thermostat TP1 open (Thermal shutdown) or not

working.

Electronic board PC1

Place S3 in ON position if no remote control is

used.Place S3 in REMOTE position and be sure remote

control is connected to receptacle RC2.

Check and repair or replace remote control device.

Allow unit to cool for approximately 15 minutes with

fan on.

Consult your dealer or Service Center to review unit.

Line disconnet switch in the OFF position.

Line fuse (s) open.

Improper electrical input connections.

Input voltage jumpers links not in proper positions.

Power switch.

Place line disconnect switch in the ON position.

Check and replace line fuse(s).

See section 3-8 for proper input connections.

See section 3-8 for proper jumper link position.

Check and replace S1 if necessary.

Summary of Contents for ALPHA TIG 252 - DP

Page 6: ......

Page 30: ...NOTES...