ADCP-90-606 • Rev C • May 2020

Page 33

© 2020

CommScope

. All Rights Reserved.

6.3

Mounting the RapidReel Cable Spool Trays in the Panel Shell

After the microcables have been completely unwound from the external spool, each RapidReel

cable spool tray must be mounted in the panel shell. The spool assemblies may be installed in

the panel shell from either the front or rear side. After unwinding the microcables as far as

possible toward the far end termination point, return to the shipment pallet and unpack and

install the RapidReel cable spool trays as follows:

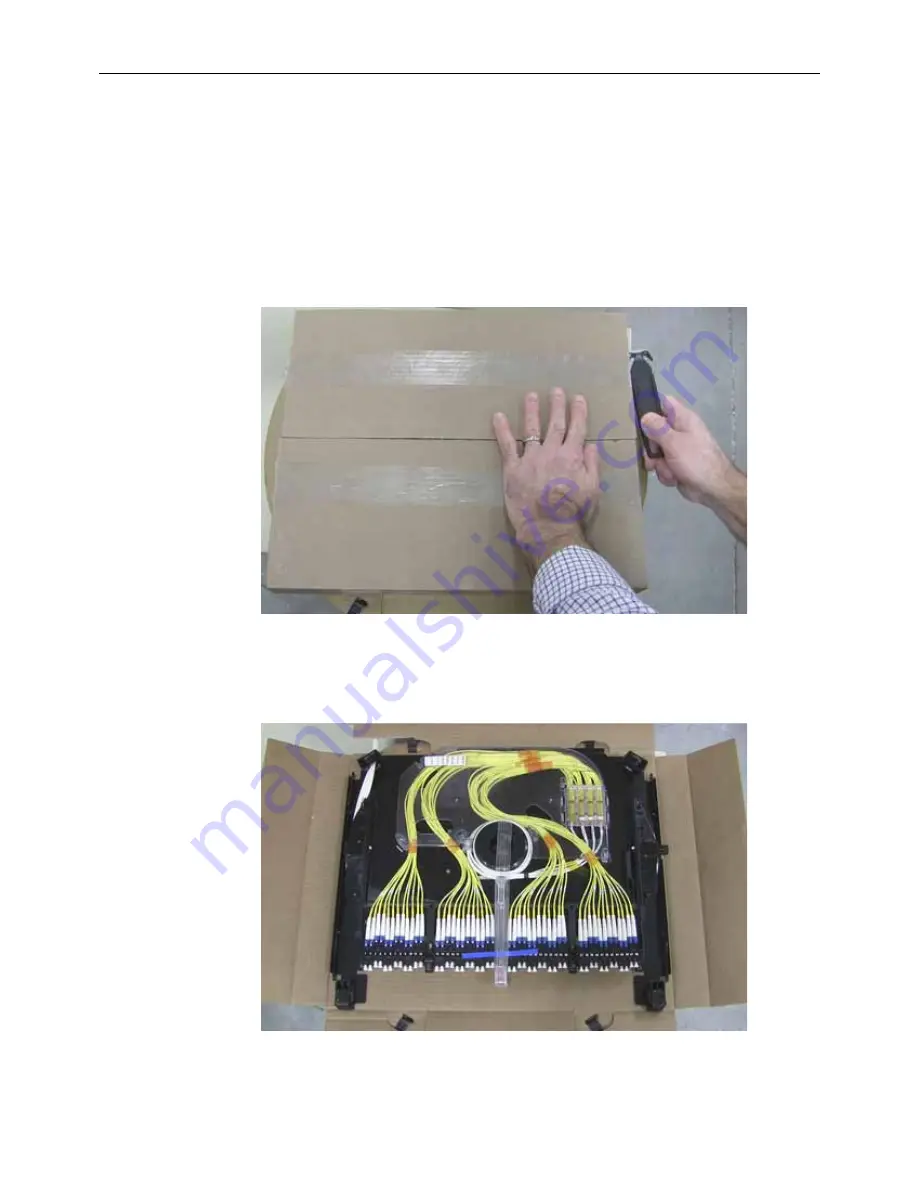

1. Use a box cutter to open the box on top of the external spool as shown in

.

Figure 39. Opening Box on Top of External Spool

2. Open the box as shown in

Figure 40. Opening Box and Removing Tray