Troubleshooting

7

2

:

When grayscale engraving and the zero return engraving is used as the starting point, the X-axis

keeps hitting the edge of the product after a period of normal engraving

Solutions:

1

:

Please check whether the setting size of the engraving image is more than

400*400

;

2:

:

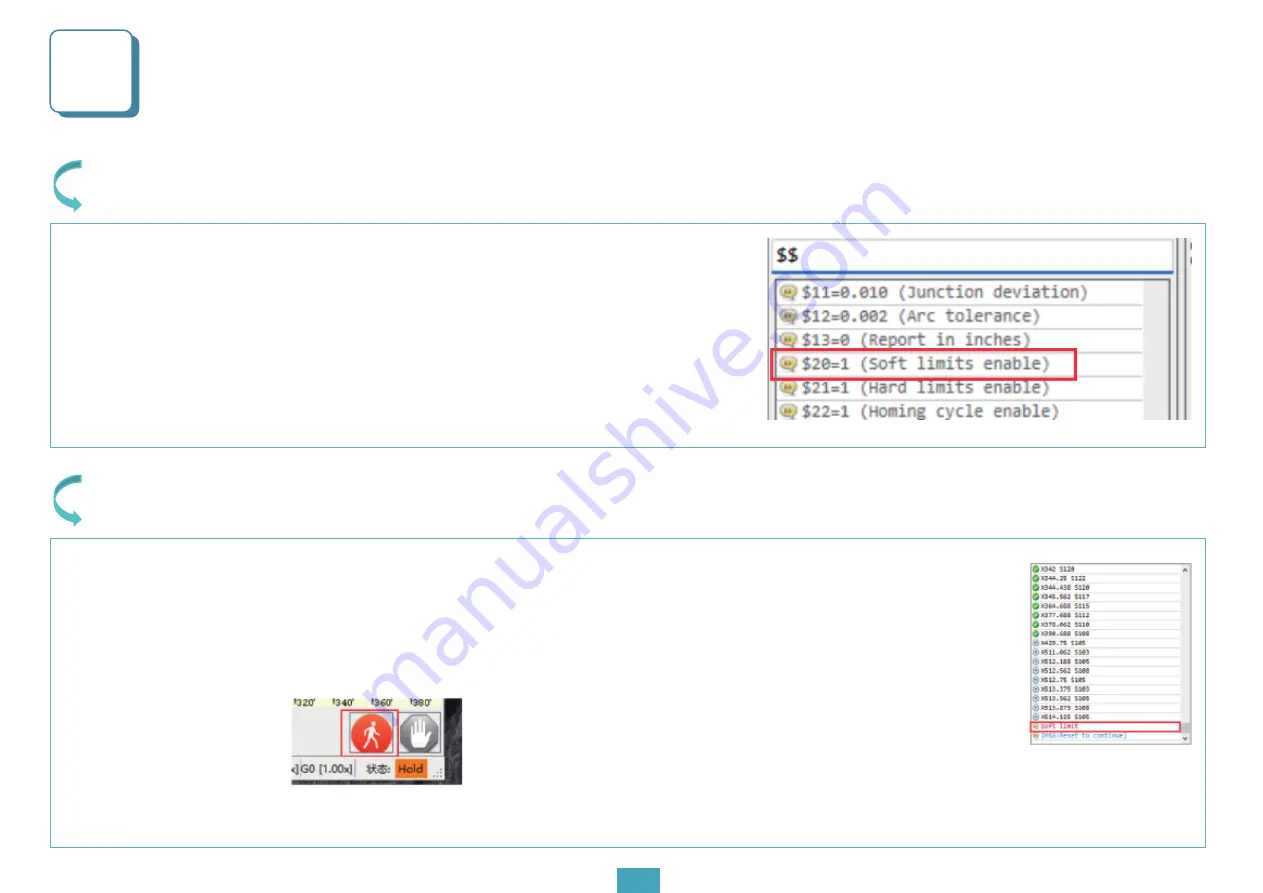

Enter $$ and check whether it is $20=1. If not, then modify $20=1 to start

the soft limit switch, which can prevent the carving range from exceeding

400 when set by human or other abnormal conditions

;

15

3

:

If the machine does not move during the engraving process

;

Solutions:

1

:

Please check whether GRBL is connected to the machine

;

2

:

Please check whether the product power supply has power supply, check the red indicator

;

3

:

If there are no problem with the above operations, please check whether there is a red alarm in the

lower right corner of GRBL software. If so, it means the gyro alarm has been triggered, please enter $$ value

to check $140 value. It is recommended to set it to 16 after clicking the start button to lift the alarm.

4

:

If none of the above operations reveal a problem, check whether the progress meter triggers a soft limit.

If so, please click the reset button, the unlock button and click start engraving.