13

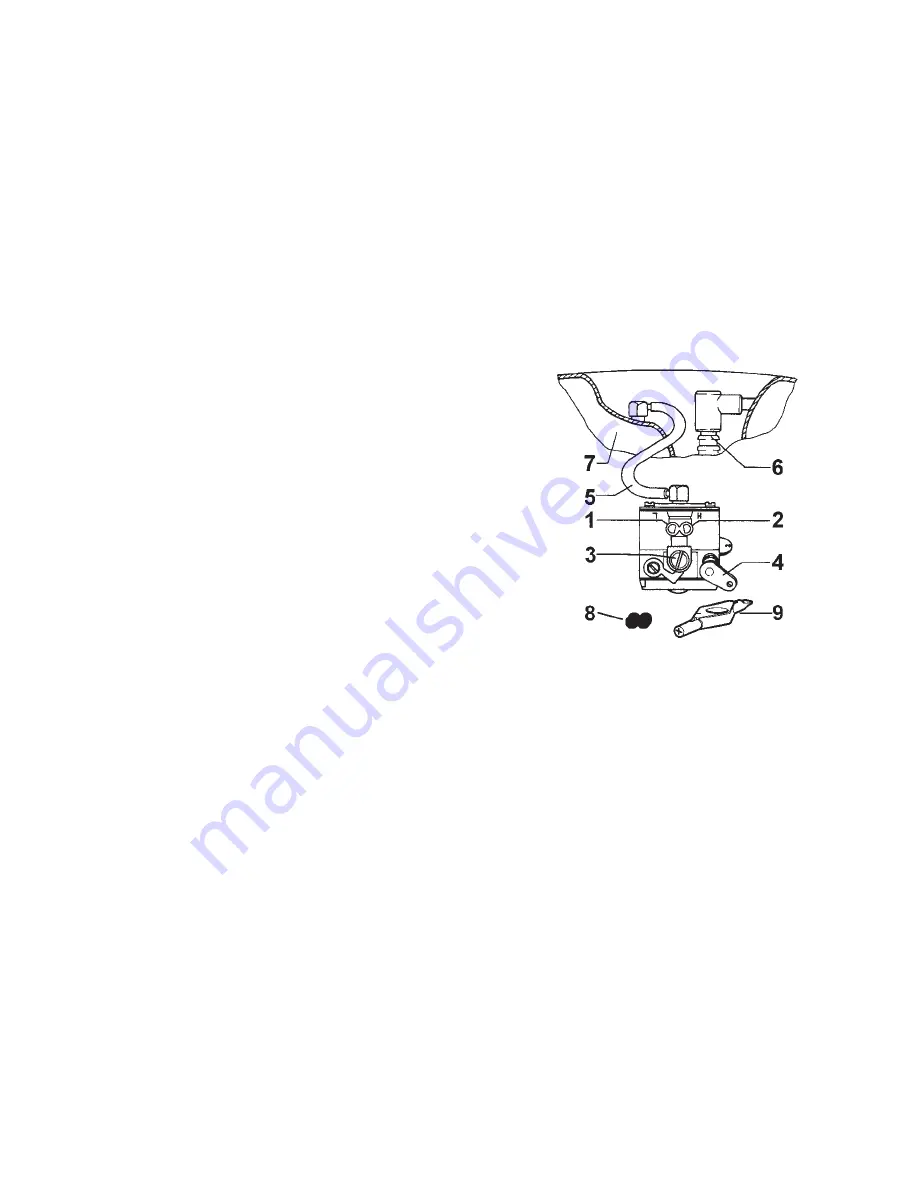

7 - CARBURETTOR

- The Aquascooter has a carburettor with two membranes. The first membrane

acts as a pump, drawing the fuel from the tank and into the engine as required.

Faults involving this pump-membrane are extremely rare.

- The second membrane, located in the bottom part, regulates the flow of fuel and

needs to be connected to the external atmospheric pressure so as to regulate

the fuel to suit the engine’s needs. In normal engines that do not run in the water,

this is done with a simple hole in the cover of the membrane. The Aquascooter’s

carburettor has to run in the water, so this system cannot be used. There is

therefore a rubber tube connecting the carburettor to the atmospheric pressure in

the air tank (5, fig.7).

7.1- ADJUSTMENTS.

1 - Idling/Medium rate adjuster screw ( L )

2 turns

2 - Full throttle (H) rpm adjuster screw 1

and 3/4 turns

3 - Idling adjuster screw

4 - “Start and Run” lever

5 - Membrane pressure compensation tube

6 - Spark plug

7 - Air tank

8 - Rubber stopper for closing the carburetor

screws

9 - Adjusting key

- This engine has been designed and built in accordance with CARB-EPA

Exhaust Emission Standards

.

- The Exhaust Emission Control System includes the fuel system, the intake system

and, more importantly, the carburettor:

designed to allow only adjustments of

screws L and H in a preset range established by the manufacturer that

cannot be modified by the user

.

You can only adjust the throttle valve “idling” adjuster screw (3, fig. 7) to regulate

the engine in the water if it stops when idling.

7.2 - WARNING: With the Aquascooter out of the water and the accelerator at full

throttle, the engine must always be abundantly supplied with fuel, otherwise you

will not obtain maximum power in the water.

If faults or fuel problems occur, contact your nearest dealer who can adjust the

relevant screws

L

and H by 1/8 of a turn with a special wrench, to find the optimal

setting and allow the engine to function without stopping in the water.

fig.7