INSTRUCTIONS FOR TECHNICAL PERSONNEL

31

6)DETERGENT DOSAGE (for machines with built-in detergent dispenser)

With the screw on the side of the detergent pump, close completely the

product intake, then slowly open the screw until the desired intake quantity has

been reached. The correct quantity is indicated by the detergent supplier.

Check that the intake of the pipe during the rinse cycle is as preset. (1cm = 1g

approximately). Maximum intake or delivery distance: 2 meters.

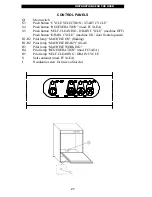

To see the image for the detergent immission hole in the tank.

To see the electrical diagram enclosed for the electrical connection

(cables nr. 10 and 7).

Summary of Contents for FC54-E

Page 3: ...19 INSTRUCTIONS FOR USE ...

Page 18: ...05 2001 CODICE 900173 ...