Page

5

of

40

FABJET GRAND

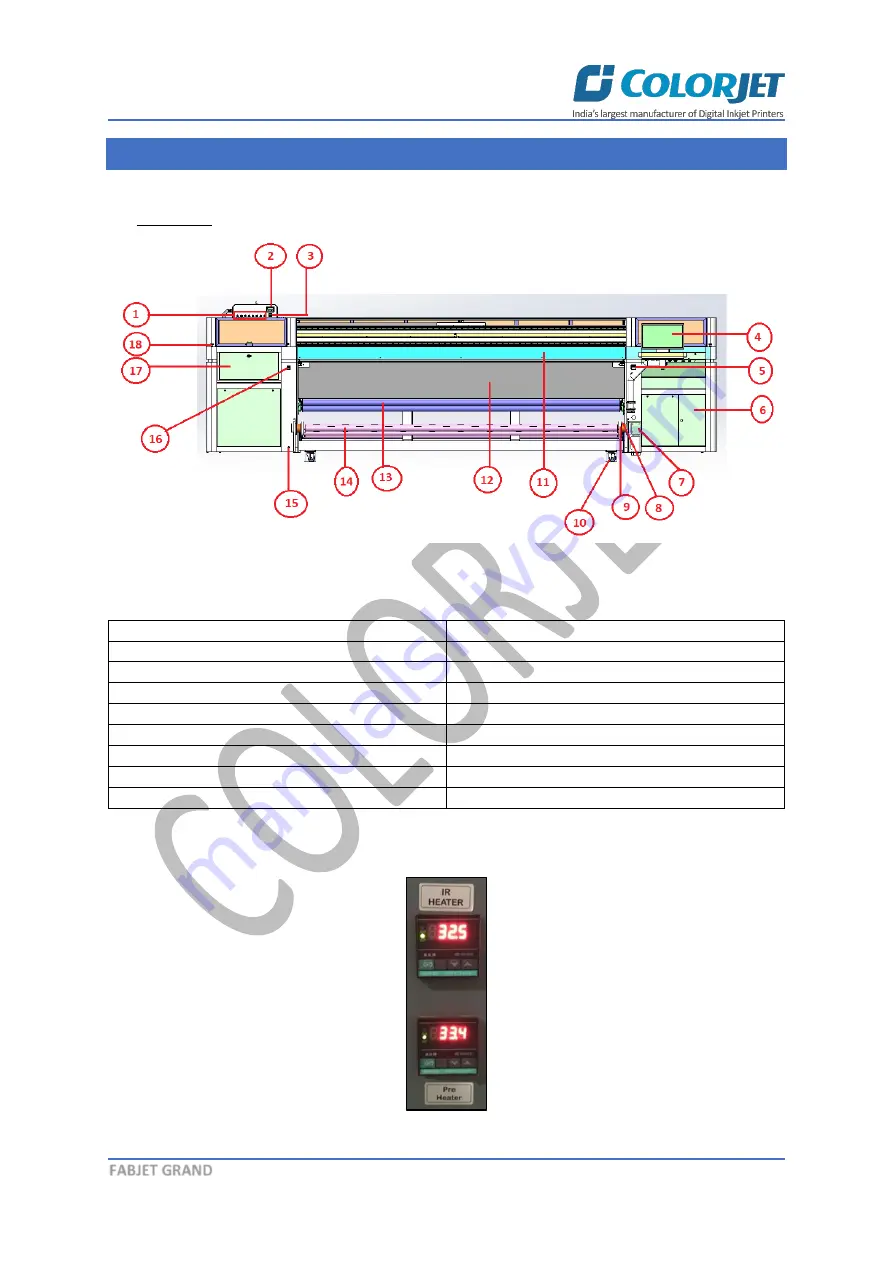

2. Machine Overview

Front View

The

Front View

of the machine is shown in the image below:

Fig 1: Displaying the Front View

Table 1: Different Parts of the Machine

1.

Ink Valves

2.

Head Height Meter

3.

Negative Pressure Meter

4.

LCD Panel

5.

Print Dryer Controller

6.

Electric Housing Cabinet

7.

Take Up Motor

8.

Take Up Sensor

9.

Safety Chuk

10.

Wheel

11.

Front Panel

12.

Print Dryer

13.

Guiding Roller

14.

Take Up/Air Shaft Roller

15.

Air Outlet

16.

Air Pressure Meter

17.

Purging /Capping Station

18.

Emergency Button

The IR Heater and Pre Heater are shown in the image below:

Fig 2: Displaying the IR Heater and Pre-Heater Controller