12

6X-1086

3230 CAMERA

INSTALLATION MANUAL

likely have its own unique requirements.

A 3230 can be ordered with any one of five

mounting arrangements. One of these is related

to direct base plate mounting for the 3230 and the

remaining four use mounting arms and brackets for

an installation.

Before preparing to mount a 3230 it is impor

-

tant to have either pre-installed the system cable or

to have verified that the cable can be routed to the

location of the mounting assembly. This often re

-

quires pulling cable through conduit and other tight

places. It is also necessary to plan for weatherproof

-

ing any through-wall holes.

Note that the Pedestal mount and the Ceiling

mount are the same mechanical assembly. The only

difference is in which direction they are mounted.

4.1 Pedestal (PEDD) Mount (same as Ceiling

mount)

The pedestal mount (figure 10) has a round

bottom plate with four mounting holes and a move

-

able head at the other end of a pedestal column.

The head is adustable for up/down and right/left.

The hole pattern on the moveable head aligns with

the threaded holes on the bottom of the camera.

4.2 Ceiling (CEIL) Mount (same as pedestal

mount)

The ceiling mount (figure 10) has a round plate

for securing to the ceiling with four fasteners and a

repositionable head at the bottom end to which the

camera can be bolted for movement up/down and

right/left.

4.3 Pole Mount (POLE)

The pole mount (figure 11) attaches to vertical

poles using stainless steel straps. The curved arm

projecting from the mounting plate has an adjust

-

able head so that the mounted camera can be ad

-

justed in azimuth and elevation to cover the scene

of interest.

4.4 Mast Mount

The Mast mount (figure 12) straps to horizontal

arms. Stainless steel straps are used to secure the

mount to the arm. An adjustable head on the end of

a short pedestal provides for moving the camera in

azimuth and elevation for coverage of the scene of

interest.

4.5 Heavy Duty Wall Mount (HDWM)

This heavy duty wall mount (figure 13) secures

with two bolts. These holes are slotted so that final

alignment can be done in the event that the bolt

holes or studs are not perpendicular. A moveable

assembly on the end provides for movement in azi

-

muth and elevation.

5.0 Supplementary Information

This section covers handling the shipping the

camera.

5.1 Unpacking and Receiving Inspection

This item was thoroughly tested and carefully

packed in the factory. Upon acceptance by the car

-

rier, they assume responsibility for its safe arrival.

Should you receive this item in a damaged condi

-

tion, apparent or concealed, a claim for damage

must be made to the carrier.

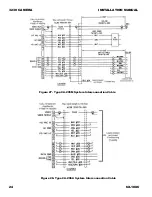

Figure 8. Pin Location Diagram,

Model 3232, Model 3234, and Model

3235 Cameras