EN

G

LI

S

H

8

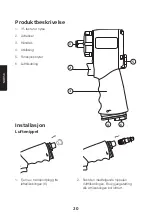

Instructions for use

Undoing nuts/bolts

1. Fit a hexagon impact socket which fits exactly onto the head of the screw/bolt or

nut which you want to undo onto the anvil of the impact wrench (1).

2. Fit the socket fully over the nut/bolt you wish to loosen.

3. Grip the impact wrench firmly by the handle (3).

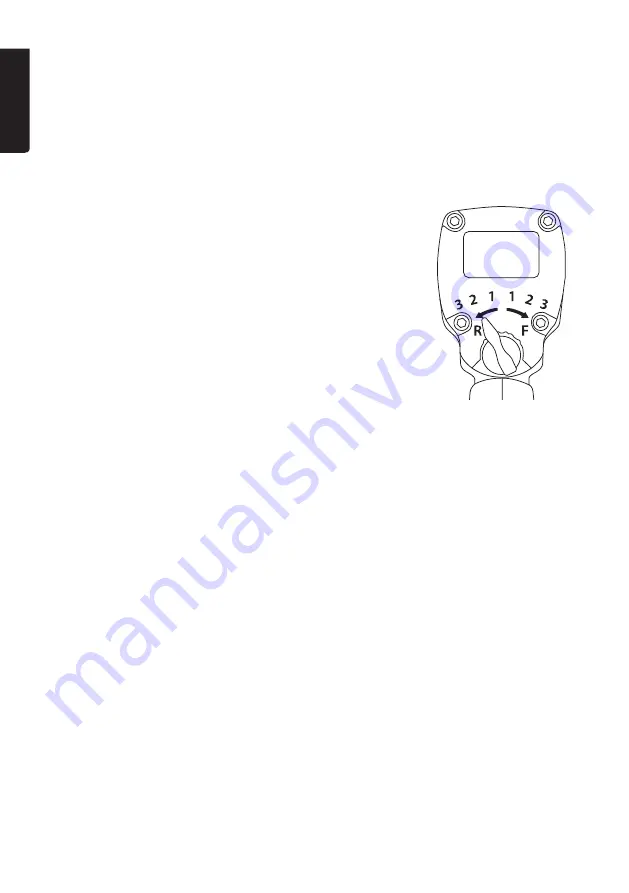

4. Turn the selector (5) left to the reverse position (R) and choose

an impact force 1, 2 or 3 (low–medium–high). Always begin

with the lowest force (1) and then increase if necessary.

5. Pull the trigger (2).

Note:

Do not run the impact wrench for more than 15 sec at

a time in the same direction if the nut/bolt does not loosen. If

the nut/bolt does not come undone:

• Change the direction of rotation using the selector (3)

and drive the impact wrench in the opposite direction for

a couple of seconds.

• Switch the direction of rotation back again and run

the wrench in the original direction.

Tightening nuts/bolts

Note:

• When doing up nuts/bolts using an impact wrench, a torque bar (sold separately)

with the correct torque setting should be inserted between the impact wrench and

the impact socket, otherwise the nut/bolt might be overtightened and damage

the fastener and/or the material it is fastening.

• When fitting wheels onto vehicles a final check of the wheel nut/bolt torque should

always be made using a torque wrench.

1. Screw the wheel nuts/bolts in place by hand at least 3 complete turns in order to

prevent damaging the threads when they are tightened using the impact wrench.

2. Fit a hexagon impact socket which fits exactly onto the head of the screw/bolt or

nut which you want to undo onto the anvil of the impact wrench (1).

3. Fit the socket fully over the nut/bolt you wish to loosen.

4. Grip the impact wrench firmly by the handle (2).

5. Turn the selector (3) right to the forward position (F) and choose an impact force

1, 2 or 3 (low–medium–high). Always begin with the lowest force (1) and then

increase if necessary.

6. Squeeze the trigger and release it when the nut/bolt has been tightened.

Note:

After fastening, a final check of the torque should always be made using

a torque wrench.