Installation requirements

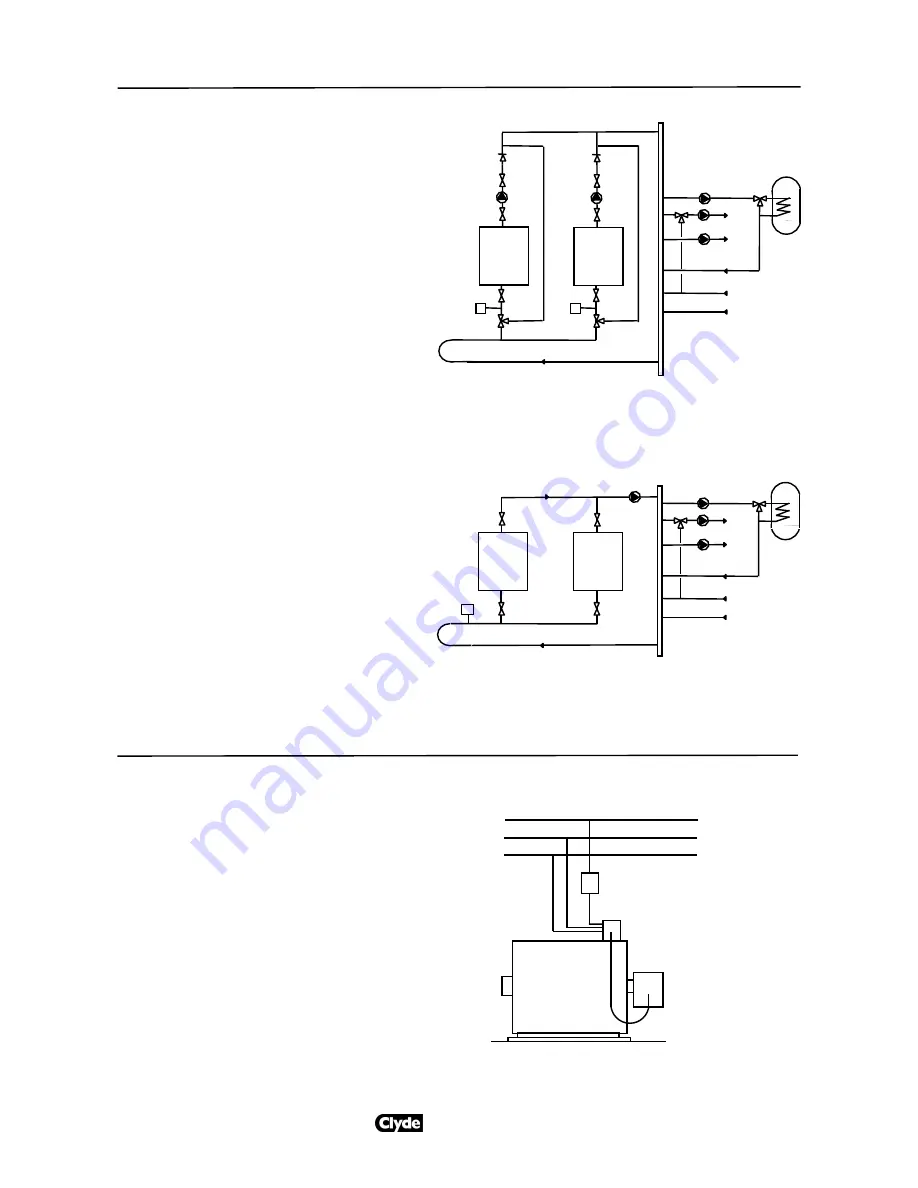

Fig 5 - Electricity supply

Electrical supply (Refer Fig 5)

230Vac 1ph burners are supplied as standard. The fused

supply should be taken to the control panel only. The

harness and connector supplied will feed the burner.

The electricity supplies to the burner and boiler control

panel must be wired in accordance with IEE Regulations. A

separate supply and isolating switch is required for each

boiler in the plant room.

All isolating switches and fuses must be provided by the

installer. Burner start/run currents for fuse specification are

available on request. Burner wiring diagrams and technical

data are also available on request.

All connections between the boiler control panel and the

burner are made through harnesses with matching plugs

and sockets, supplied as standard.

Note:

Fig 5 is only diagrammatic. Double pole switches with

the required minimum separation must always be used.

Air supply

Air for ventilation and combustion must be provided for

gas fired boilers in accordance with either BS

6644:2011 or IGE/UP/10. Air supply for oil fired boilers

must conform to BS 5410 : Part 2.

Chimney design

The CKRS boiler is designed to operate with a

pressurised combustion chamber and the chimney is

not required to assist the burner in overcoming the

boiler resistance. The chimney must cater for the total

internal resistance of the flue system from each boiler

outlet and not impose an additional load on the

burner.

Water circulation (Refer Fig 4)

The flow water temperature from the boiler must reach

60°C (gas firing) or 50°C (oil firing) within 10 minutes

of the boiler being brought into operation. Thereafter,

water circulation should be maintained through the

boiler such that the boiler flow water temperature is

always above 60°C (gas firing) or 50°C (oil firing). A

pump overrun facility is necessary to ensure that

water circulation is maintained for at least three

minutes after the boiler is switched off.

There are several ways of providing boiler protection,

eg shunt pumps, primary loops, etc. A typical boiler

pump and 3-port valve arrangement is shown in Fig

4a and b.

For multi-boiler systems a ‘reverse return’ pipework

configuration is required to ensure equal distribution

of water flow through the boilers.

Water treatment

Whenever a new boiler is connected to an existing

system, the pipework must be thoroughly cleaned and

flushed. Carnot recommend that a permanent means

of filtration be fitted into the return pipework, such as a

sludge trap, hydrocyclone or full flow duplex filters.

The boiler guarantee will be invalid if waterways are

blocked by debris or carbonate deposits. Long term

water treatment is essential to the economic operation

and life of both new and refurbished heating systems.

For full information on cleaning, flushing and

protecting hot water systems, refer to BSRIA

Application Guide AG 1/2001.

T

T

T

Fig 4a Multiple boilers with individual pumps

Fig 4b Alternative arrangement for boiler protection with a primary

loop

•

•

•

•

•

Boiler

Burner

loom

Isolator

& fuse

L

Control

panel

Burner

N

E

Single

phase

motor

EDS801/3 page5