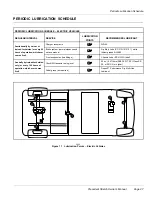

Periodic Lubrication Schedule

PERIODIC LUBRICATION SCHEDULE

PERIODIC LUBRICATION SCHEDULE – ELECTRIC VEHICLES

REGULAR INTERVAL

SERVICE

LUBRICATION

POINTS

RECOMMENDED LUBRICANT

Charger receptacle

1

WD-40

Brake system, per maintenance and

service manual.

2

Dry Moly Lube (CC P/N 1012151), white

lithium grease NLGI #2

Semiannually by owner or

trained technician (or every 50

hours of operation, whichever

comes first)

Front suspension (two fittings)

Chassis Lube - EP NLGI Grade 2

Check/fill transaxle to plug level

22 oz. (0.67 liters) SAE 30 WT. API Class SE,

SF, or SG Oil (or higher)

Annually by trained technician

only (or every 100 hours of

operation, whichever comes

first)

Pedal group (as required)

Dupont™ Performance Dry Multi-Use

Lubricant

2455

Figure 11

Lubrication Points – Electric Vehicles

Precedent Stretch Owner’s Manual

Page 27

Summary of Contents for Precedent Stretch

Page 1: ...Precedent Stretch Owner s Manual Electric Refer to back cover for applicable build code range...

Page 2: ......

Page 39: ...Warranty WARRANTY TBD Precedent Stretch Owner s Manual Page 37...

Page 40: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ...Club Car R NOTES...

Page 46: ......

Page 47: ......