CMS-2 CARBON MONOXIDE MONITOR

Page 10

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22925, Rev. I, 04/18

Figure

10

4.6.5

Allow test gas to flow through the instrument for

about one minute, or until the interior calibration

indicator light turns red.

4.6.6

After the calibration light turns red, the initial

phase of the calibration test is complete. Return the

instrument to operating mode per Section 4.8. If the

indicator light does not turn

red,

proceed with Paragraph

4.6.7.

4.6.7

If after one minute of operation with test gas the

calibration indicator light has not turned red and the

instrument has been in operation for 30 minutes,

calibrate the instrument per Section 4.7. If the instrument

has not been in operation for 30 minutes, return it to

operating mode per Section 4.8 and operate with

sample air flowing through for at least 30 additional

minutes. Re-test the calibration, and if the calibration

light does not turn red, calibrate the instrument per

section 4.7.

4.7 Calibration

4.7.1

Do not calibrate the instrument unless it has

gone through two stabilizing periods and calibration

tests, per Sections 4.3 and 4.6, and only if the calibration

indicator light has not turned red.

4.7.2

Connect the calibration connector and 10 ppm

test gas per Sections 4.4 and 4.5.

4.7.3

Place the Run/Calibration toggle toward

CALIBRATION. Slowly open the flow-control knob and

adjust the flow so the flow ball remains between 0.5 and

0.8 SCFH (normally a little nearer to 0.8).

4.7.4

Allow test gas to flow through the instrument for

about one minute. Insert a small screwdriver into the

calibration adjustment port and turn the potentiometer as

follows:

If the potentiometer is

blue

,

turn

clockwise

until the

calibration indicator light turns red.

If the potentiometer is

white

, turn

counterclockwise

until the calibration indicator light turns red.

4.7.5

Once the indicator is red, turn the potentiometer

in the opposite direction until the light turns

green

. Then,

slowly turn the potentiometer from

green

to

red

several

times to find the trip point. The monitor is calibrated at

the spot where the light turns red. Return the instrument

to operating mode per Section 4.8.

4.8

Return Monitor to Operating Mode

4.8.1

Turn the flow-control knob counterclockwise to

close the calibration-connector valve.

4.8.2

Remove the calibration tubing from the monitor

by gripping the tube-end connector, push in lightly, turn it

counterclockwise to unlock, and pull straight out.

4.8.3

Place the calibration toggle toward the RUN

position. The flow meter ball should rise to 0.5 to 0.8

SCFH. After several seconds the external alarm light

should change from

yellow

to

green

, and the interior light

should change to

green

. If the lights respond as

described, proceed with Section 4.8.4 to return the

instrument to operation. If after about one minute of

operation the lights do not change to

green

, do both of

the following:

Calibrate the instrument, per Section 4.7.

Test instrument function by applying impurity-free

air, per Section 4.9.

4.8.4

Close and latch the instrument case cover.

4.8.5

Remove the calibration connector from the test

gas. The test gas cylinder has a positive seal, whereas

the calibration connector valve does not.

NOTE: If the

connector is not removed from the test gas cylinder,

over time the cylinder will empty.

4.8.6

If the tubing needs to be removed from the

calibration connector, press and hold the slide-release

fitting and gently pull the tubing connector from the

fitting.

4.8.7

Store all material in a clean, dry area.

4.9

Impurity-Free Air (zero contamination) Test

4.9.1

This test should be done whenever the

instrument stays in an alarm condition after it is returned

to the operating mode. This test shows whether the

alarm condition is due to contaminated air or monitor

malfunction.

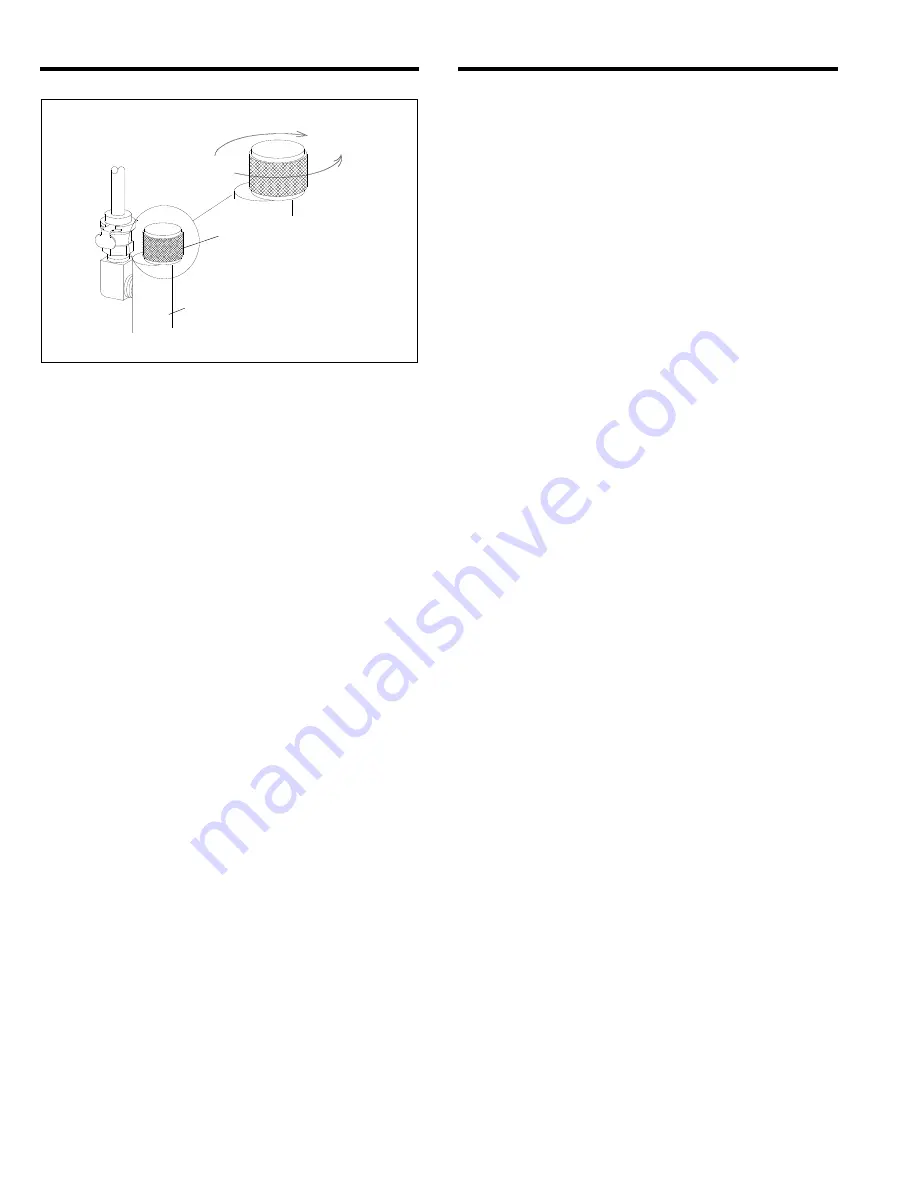

CLOSE

OPEN

Calibration Connector

Flow-Control Knob

Turn fully clockwise to close.