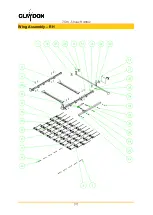

7.5m - Straw Harrow

[23]

4

NYLOC NUT M16

18

5

PP50

Plastic Plug for 50mm Round Tube

2

Straw Harrow Bars and Assembly - RH

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

SHA06

Harrow Bar 6 RH

1

SHA07

Harrow Bar 7 RH

1

SHA08

Harrow Bar 3 RH

1

SHA09

Harrow Bar 4 RH

1

SHA10

Harrow Bar 5 RH

1

2

SH0603

Harrow Tine - 16mm

6

3

SH0604

Harrow Bolt

18

4

NYLOC NUT M16

18

5

PP50

Plastic Plug for 50mm Round Tube

2