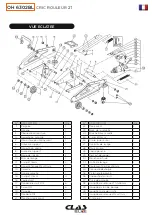

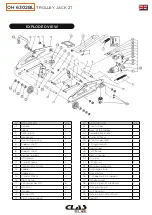

OH 6302BL

TROLLEY JACK 2T

SPECIFICATIONS

- rotating soleplate

- robust chassis

- anti-overload system

- transportation handle

- min. H.: 135mm

- max. H.: 340mm

- handle length: 740mm

- weight: 8.7kg

USE

Preparation

• Open the drain valve (1) and insert the handle (extension) supplied into the pump arm (2). In

order to distribute the oil completely, pump the handle about 6 times.

• Close the drain valve - the vehicle jack is now ready for use.

Lifting

• Place the vehicle on a fi rm, fl at surface and lock the wheels of the vehicle.

• To ensure safe lifting, position the jack at a 90° angle to the vehicle and under the appropriate

lifting point (see manufacturer's instructions).

• Insert the handle into the drain valve and close it by turning it clockwise until it stops.

• Insert the handle into the pumping arm and pump the handle until the soleplate (3) is in contact

with the vehicle.

• Check again that the jack is in place.

• Continue pumping the handle until the vehicle is lifted to the desired height.

Caution: Observe the vehicle carefully during the lifting operation. The jack must move in the

direction of the vehicle during the lifting operation. If it does not, there is a high probability that

the vehicle will slip off the jack.

• Pull the handle out of the pump arm (risk of accident!).

• Secure the load with suitable jack supports before starting work on or under the vehicle.

WARNING: It is not permitted to work on or under the vehicle without fi rst securing the lifted load

in the appropriate manner: with candles (otherwise there is a risk of accident!).

• After completing work on the vehicle, open the drain valve by carefully turning the jack handle

in small steps in an anti-clockwise direction until the vehicle begins to descend.

• Once the vehicle is on the ground, the drain valve can be opened again (about half a turn) to

bring the lifting arm (4) all the way back to the starting position.

• Before lifting the load, check that the drain valve is closed.

• All moving parts must be lubricated in accordance with the operating instructions and maintained

regularly.