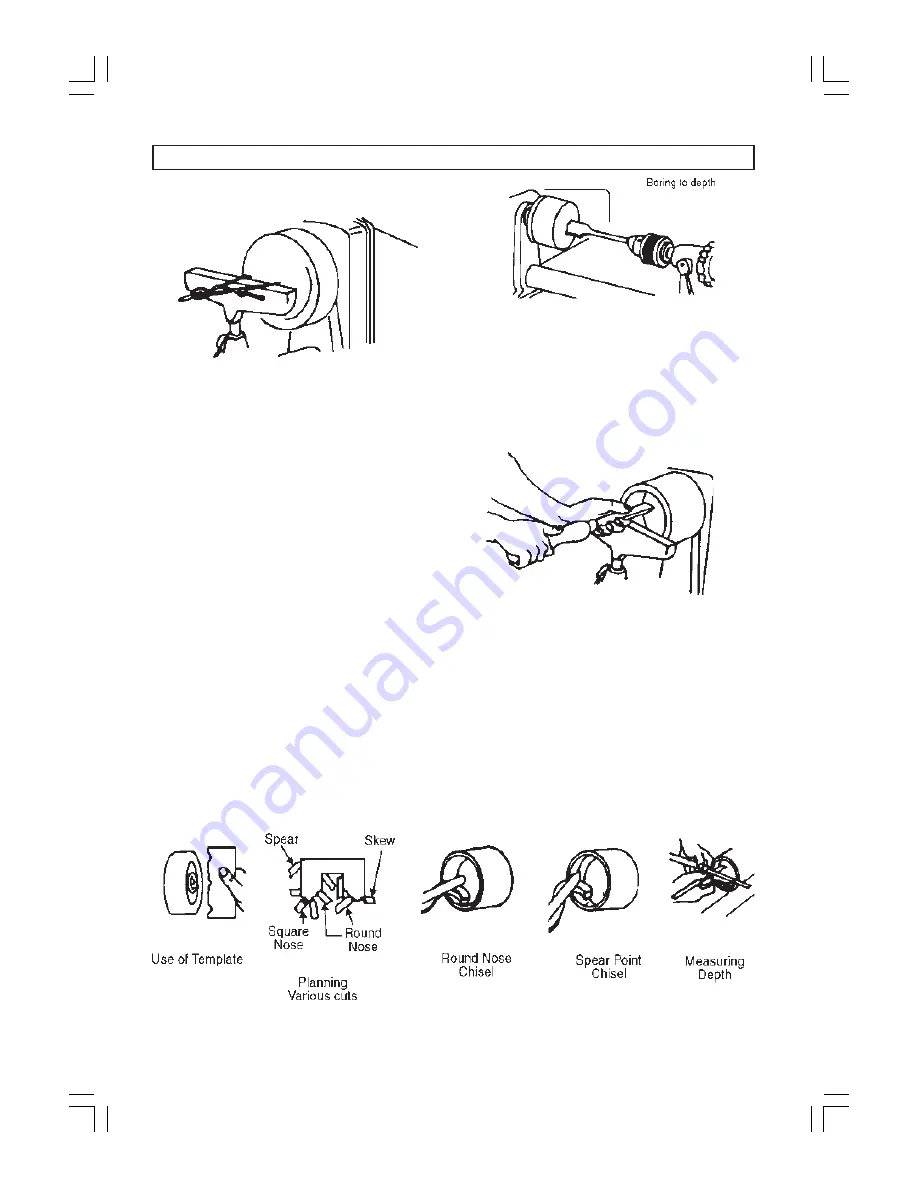

FACEPLATE & CHUCK TURNINGS

1.

PLANNING THE WORK

wood bit available. This can be accomplished

as illustrated above, or in any of the ways shown

on pages 18 & 19. Be careful to measure in

advance the depth to which the drill can be

allowed to go.

Now remove the bulk of the waste (to rough-

out the desired recess), by scraping with the

round-nose chisel or the gouge. Remove up to

within 1/8” of finished size in this manner.

Make a layout first, to provide a visual pattern

to follow while working the turning. Patterns can

be laid out in the same manner as spindle

patterns, or templates can be made which can

be held against the work for visual comparison.

Circles to locate the various critical points (at

which the contours of the faceplate take distinct

form) can be quickly scribed on the rotating

work by using dividers (see above).

2

PLANNING VARIOUS CUTS

The circumference of a faceplate turning is

roughed-out and finished in the same manner

as that for a spindle. Practically all of the

balance of the operations however, are done

by using scraping methods.

A few of the standard contours which are often

turned are illustrated in fig.56, which also shows

the proper chisels for shaping these contours.

Any roughing out to depth that must be done is

generally accomplished with the gouge held in

the scraping position.

3.

DEEP RECESSES

The first step is to remove as much wood as

possible by boring into the centre with the largest

Finish off the inside circumference by scraping

with the spear point chisel or skew. Smooth the

bottom of the recess by scraping it flat with the

flat nose chisel.

Proper support must be provided at all times for

the scraping chisels. Several tool rest positions

are shown in the accompanying illustrations.

Always endeavour to position the part of the rest

that supports the tool as close to the working

surface as possible.

The depth and squareness of the sides of the

recess can be quickly checked by holding one

of the straight sided chisels and a combination

square as shown.

29

Fig. 56

Fig. 57

Fig. 55

Fig. 58