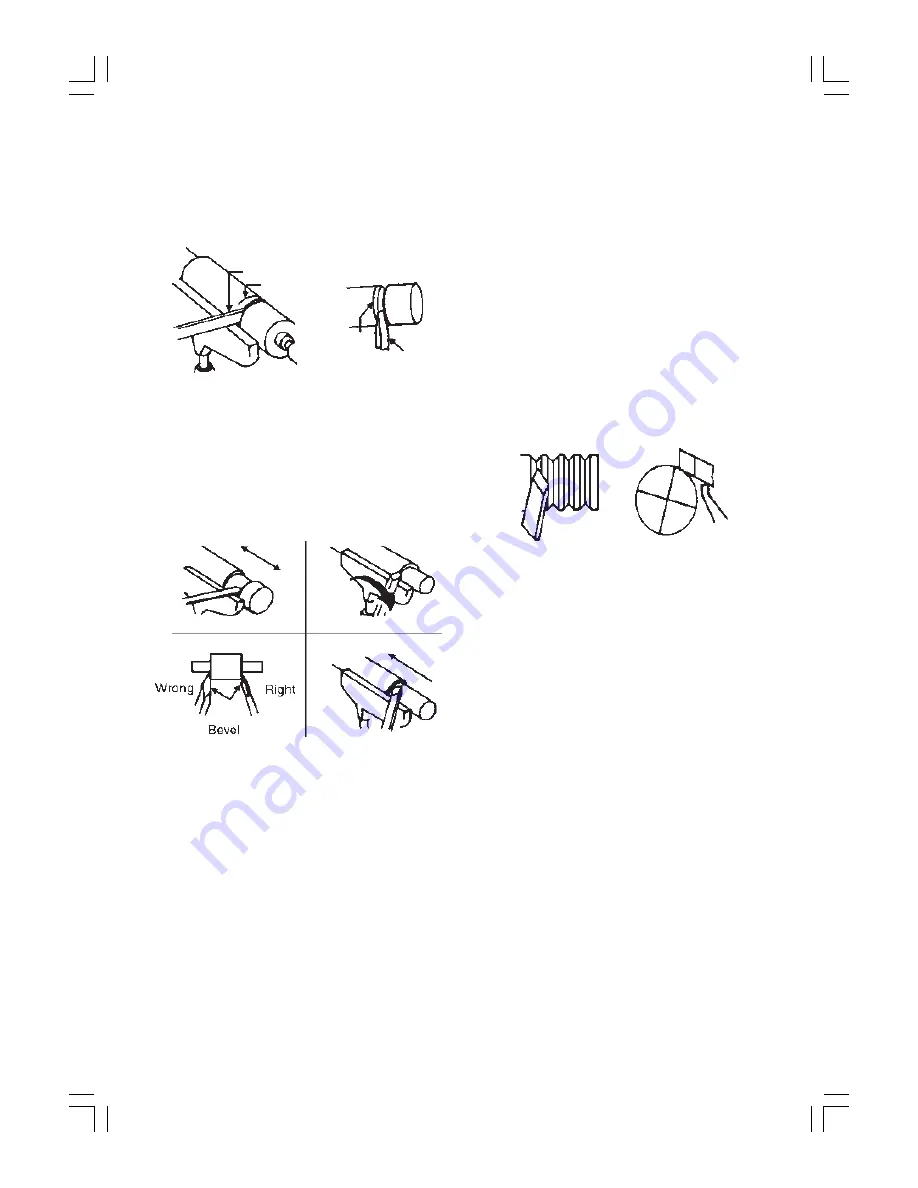

Use the gouge to remove any waste stock

outside of shoulder, and smooth this section up

to within 3mm of the shoulder in the usual

manner. Finishing of the shoulder unless it is more

than 25mm high is best done with the 1/2” skew.

First, the toe of the skew is used to remove

shavings from the side of the shoulder, down to

finish size. Hold the skew so the bottom edge of

the bevel, next to shoulder, will be very nearly

parallel to side of shoulder, but with the cutting

edge turned away at the top, so that only the

extreme toe will do the cutting.

If the cutting edge is flat against the shoulder,

the chisel will run. Start with the handle low, and

raise handle to advance toe into the work.

Cut down to finished diameter of outside area,

then clean out the corner by advancing the

heel of the skew into it along the surface of the

outside area.

Tilt the cutting edge with handle raised up, so

that only the extreme heel does this cutting. If

the shoulder is at the end of work, the process is

called squaring the end. In this case, reduce

outer portion to a diameter about 6mm larger

than tool centre diameter, then later saw off the

waste stock.

6.

CUTTING VEES

Vee grooves can be cut with either the toe or

heel of the skew. When the toe is used, the

cutting action is exactly the same as in trimming

a shoulder, except that the skew is tilted to cut

at the required bevel. Light cuts should be taken

first on one side then the other, gradually

enlarging the vee to the required depth and

width.

When the heel is used, the skew is rotated down

into the work, using the rest as a pivot.

Otherwise, the cutting position and sequence

of cuts is the same.

As when using the toe, it is important that cutting

be done only by extreme end of cutting edge.

If deep vees are planned, it is quicker to start

them by making a sizing cut at the centre of

each vee. Vees can also be scraped with the

spear point chisel or a three-sided file.

7.

CUTTING BEADS

This requires considerable practice.

First, make pencil line to locate the tops (highest

points) of two or more adjoining beads. Then

make a vee groove at the exact centre

between two lines, and down to the desired

depth of the separation between the beads.

Be careful not to make the groove too wide or

you will remove portions of the desired beads.

The sides of the two adjoining beads are now

cut with the heel of the skew, preferably 1/2”

size, unless beads are quite large. Place the

skew at right angles to the work axis, flat against

the surface and well up near the top. The

extreme heel should be just inside the pencil line

that marks the top of the bead.

24

5.

CUTTING A SHOULDER

A shoulder can be the side of a square portion

left in the workpiece, the side of a turned section

or the end of the workpiece. Most shoulders are

perpendicular to the work axis, but a shoulder

can be at any angle desired.

First, mark position of the shoulder with a pencil

held to the revolving workpiece. Then make a

sizing cut with the parting tool, placing this cut

about 2mm outside the shoulder position and

cutting to within about 3mm of the depth

desired for the area outside of the shoulder.

If shoulder is shallow, the toe of the skew can be

used to make the sizing cut, but do not go in

deeper that 3mm with the skew unless wider and

wider vees are cut to provide clearance for this

tool.

Fig. 41

Fig. 42

Fig. 40