16

Parts & Service: 020 8988 7400 / E-mail: [email protected] or [email protected]

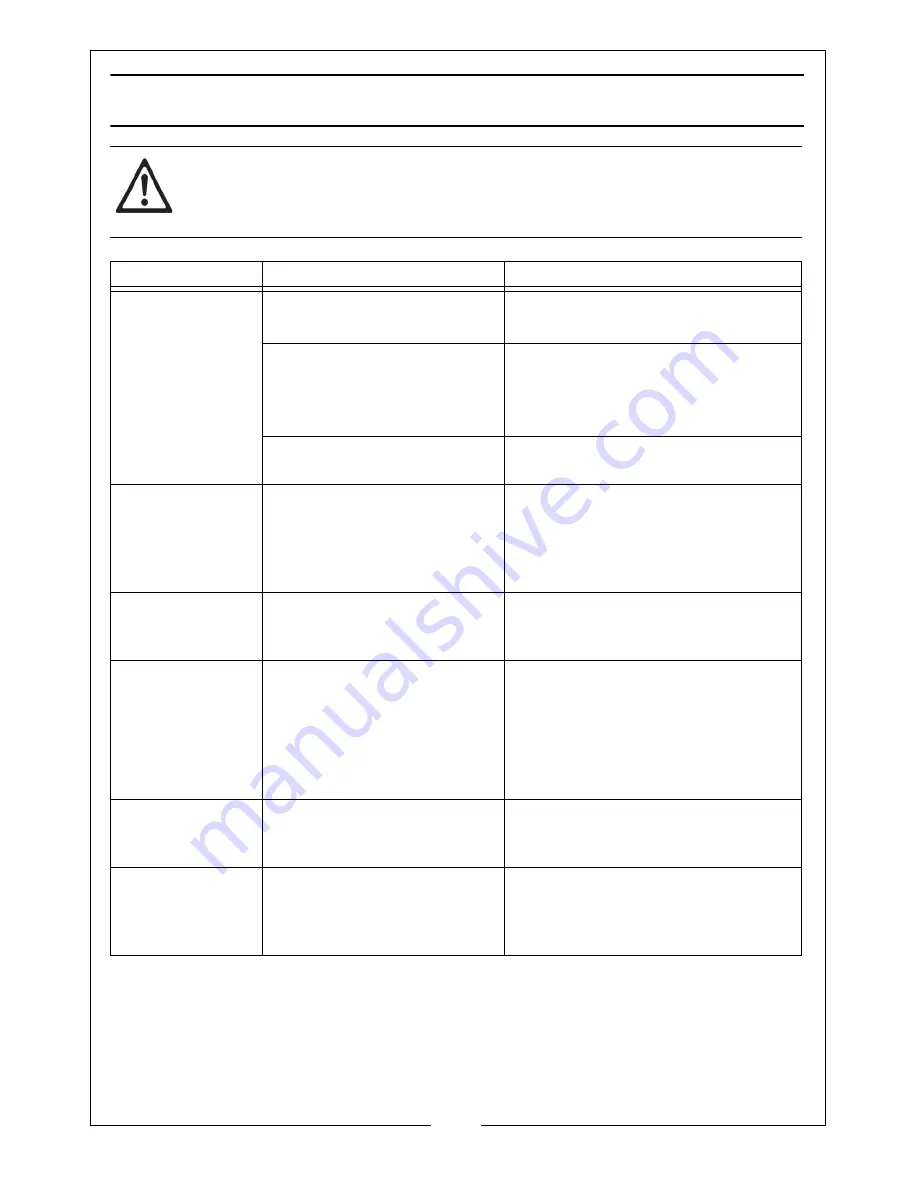

TROUBLESHOOTING

CAUTION: DO NOT TRY TO REPAIR OR ADJUST THIS COMPRESSOR IF YOU

ARE UNCERTAIN. IF YOU HAVE ANY QUERIES, CONTACT YOUR DEALER.

PROBLEM

PROBABLE CAUSE

REMEDY

The compressor

has stopped and

does not start.

Bad electrical connections.

1.

Check electrical connections.

2.

Clean and tighten if necessary.

Overload cutout switch has

tripped.

1.

Switch off and wait approx 5

minutes.

2.

Press the reset button and

switch on again.

Motor windings burnt out.

1.

Contact your Clarke dealer for

a replacement motor.

The compressor

does not reach

the set pressure

and overheats

easily.

Compressor head gasket

blown or valve broken.

1.

Return the machine to your

nearest service agent.

Compressor does

not start.

The reservoir has already fully

pressurised.

1.

Open drain valve to expel air.

Compressor should start again

when pressure reduces.

Air leaking from

the non-return

valve when the

compressor is not

running.

Faulty non-return valve.

1.

Drain receiver completely of

air.

2.

Remove the valve end plug,

3.

Carefully clean the valve seat

and the gasket

4.

Reassemble.

Air pressure from

the regulator will

not adjust.

The diaphragm within the

regulator body is broken.

1.

Replace regulator

The compressor is

very noisy and

makes a metallic

knocking sound.

Compressor damaged and

needs overhaul.

1.

Return the machine to your

nearest service agent.

Summary of Contents for RACER 9/50P

Page 24: ......