o

11

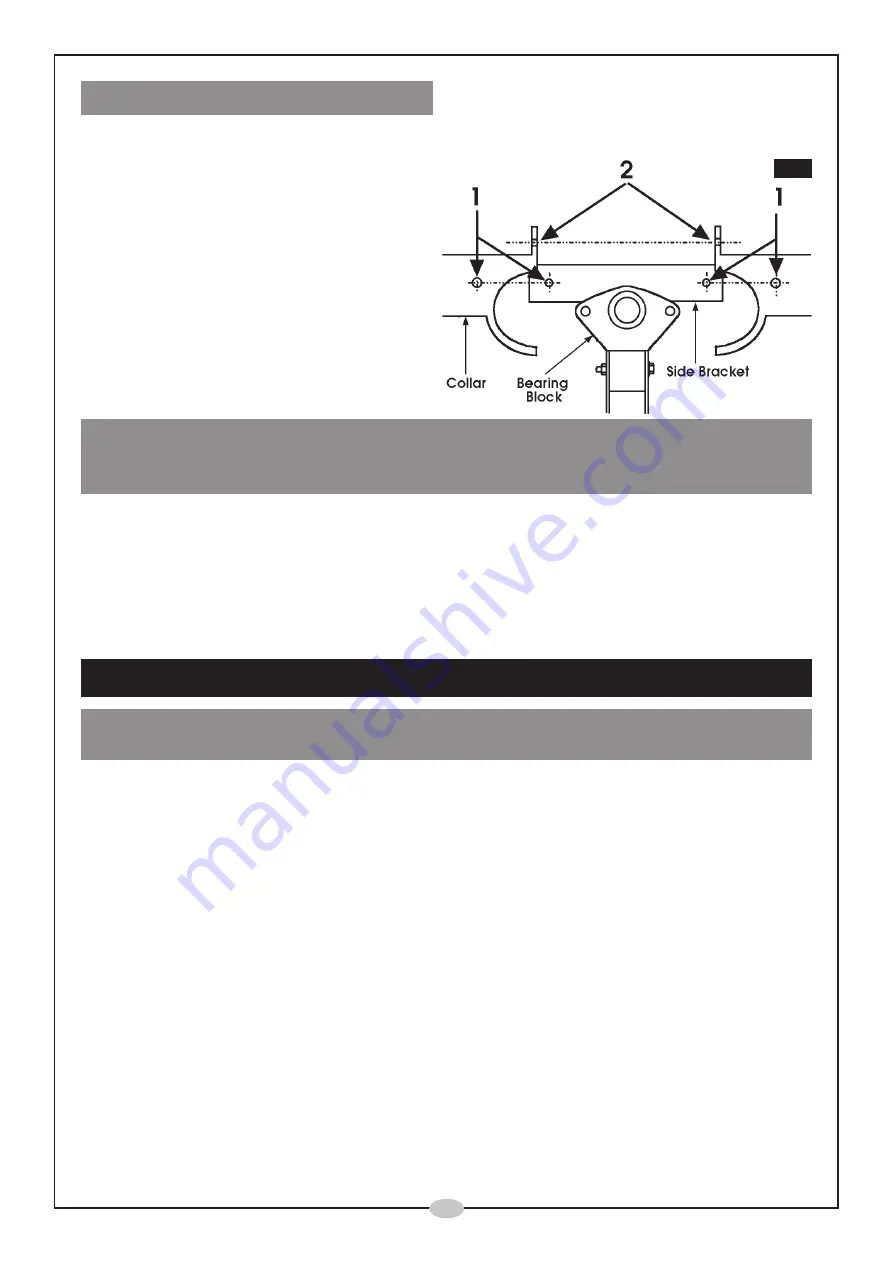

9. Fitting the Drum Collar

Before the collar is attached, it is strongly recommended that a layer of grease (not supplied)

be applied to the underside of the serrated rim of the lower drum.

9.1 Secure each half of the collar to the

side brackets first. (Shown at ‘1’, Fig.

12). Use a single M6 x 10mm bolt with

a flat and spring washer.

9.2 Bolt the two halves together using two

M6 x 20mm bolts with a flat washer,

spring washer and nut, shown at ‘2’

Fig.. 12

Fig.12

IMPORTANT:

The Drum Collar is a Safety Feature, and must ALWAYS be in place. NEVER operate the

machine with the collar removed.

Congratulations......your Concrete Mixer is now fully assembled and ready for use.

Please consult the engine manufacturers handbook, enclosed, for full details as to how to

start, operate and maintain your engine.

OPERATION

IMPORTANT:

ALWAYS start the engine and have the drum rotating, BEFORE loading the drum.

To start the engine please refer to the manufacturers handbook which accompanies this

manual.

In addition to the precautions laid out in the engine manual, ensure the throttle is set to fully

open, i.e. against the stop, before pulling the recoil starter. In this position, the engine is set to

run at an ideal speed for drum rotation.

NOTE:

If the choke is used to start the engine, it is advised that you allow the engine to warm

up sufficient for the choke to be disengaged, before loading the drum.

Once the engine is running smoothly, and the drum rotating, proceed to load the drum with

sand/cement, ensuring the drum is inclined upwards (approx. 30 degrees minimum), to avoid

having the mix thrown out.

In order to rotate the drum, push the Hand Wheel inwards at the rim to disengage the wheel

from the Locking Plate. Turn the drum to the required position then release the handwheel to

lock it in that position.

Summary of Contents for 3400820

Page 14: ...o PARTS DIAGRAM 14 14...

Page 16: ...o...