13

Use with power supply voltage and output in the

specified range.

Applying a voltage that is outside of the specified

range may cause malfunction, damage to the

sensor, electrical shock, and/or fire.

Do not use any load that exceeds the rated output.

Using such a load may result in damage to the

output part or fire.

Check the wire color and terminal No. when

connecting wires.

An overcurrent protection circuit for the output

transistor and a protection circuit for erroneous

wiring, which uses diodes to prevent reverse

connection, are implemented, but these do not

protect against all incorrect wiring. Incorrect wiring

can result in malfunction, failure, or damage to the

sensor.

Check the instruction manual for wiring colors and

terminal numbers in order to ensure correct wiring.

Check wiring insulation.

Check that wires do not come into contact with

other circuits, that no ground faults occur, and that

the insulator between terminals is not defective.

Otherwise, overcurrent may flow into the sensor,

causing damage.

Keep the cable far away from power cords or other

things that may cause noise. Noise can cause

malfunctions.

Keep unused wires from coming into contact with

other wires.

Do not short-circuit the output transistor.

When a load is short-circuited, overcurrent

protection circuit is triggered to prevent damage to

the output transistor; however, if this state persists,

the output transistor could be damaged.

Overcurrent protection .....approx. 50 mA

Do not use a load that can produce surge voltage.

While an element that protects against surge is

inserted, repeated exposure to surges can lead to

damage. Use relays and solenoid valves that are

equipped with surge absorption elements. If there

is a surge source on the same power supply line,

similarly implement surge protection.

Make sure that the lead wire is free of repeated

bends and tension. This may lead to disconnection.

Pipes can be installed vertically, horizontally, or in

any other orientation. Note that pipes should be

installed so that the fluid constantly fills the piping

while it flows through the pipes.

When installing a pipe vertically, making the fluid flow

upward can reduce the influence of air bubbles inside.

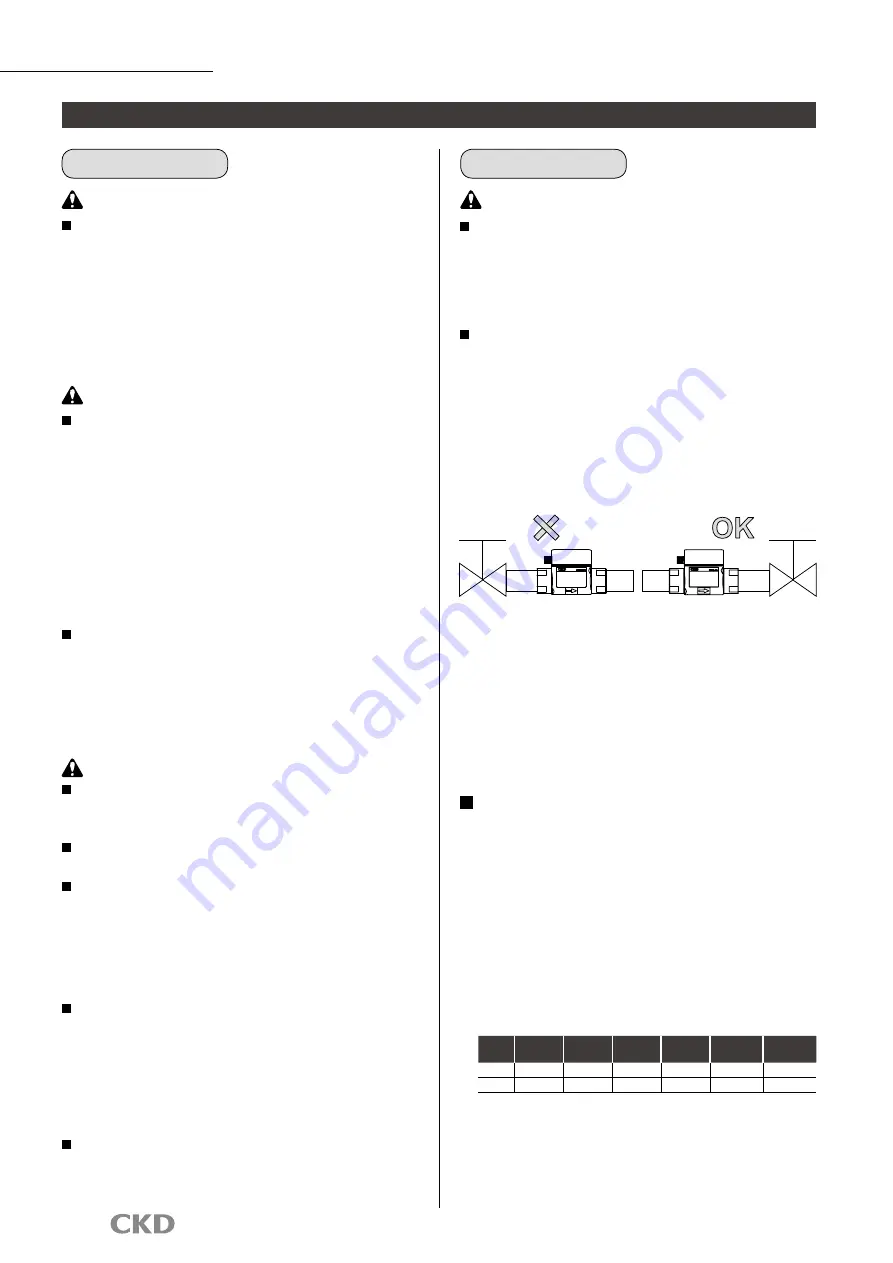

If a pipe is narrowed just before the flow rate

sensor, or if there is a valve or other restricting

component on the primary side, cavitation occurs

inside the pipe, preventing accurate measurement.

For this reason, such piping should be installed on

the secondary side of the sensor.

Cavitation...(Vapor cavities that form due to the static

pressure at end points, such as a ship propeller,

dropping below the vapor pressure of the water.

Reduced efficiency or screw damage may result.)

However, operating the pump with the secondary

side valve closed may cause the flow rate sensor

to detect pressure waves from the pump, resulting

in incorrect indication. If this occurs, install the

valve on the primary side. When doing so, ensure

that a straight pipe with a diameter of 10 times or

more bore size is installed between the valve and

the flow rate sensor.

Mounting, installation and adjustment

DANGER

WARNING

CAUTION

CAUTION

1. Wiring

2. Piping

Using an elbow or bush in the piping

When using an elbow or bush in the piping, provide straight

piping sections of at least 10 D on the IN side and 5 D on

the OUT side when using a WFK2-100 or WFK2-250 Series

model. Note that bore size change by bush should be

limited to one size. Without a straight pipe, measurement

accuracy can be compromised due to disturbances in the

flow rate and/or pressure distribution.

(Straight pipes are not necessary for the WFK2-005,

WFK2-020, and WFK2-050 Series. However, it is

recommended that a straight pipe is installed to ensure

stable measurements.)

* "D" here indicates the inner diameter of the piping material.

Refer to the table below for specific values.

Bore size Rc3/8

(10A)

Rc1/2

(15A)

Rc3/4

(20A)

Rc1

(25A)

Rc1 1/4

(32A)

Rc1 1/2

(40A)

5D

50 mm

75 mm 100 mm 125 mm 160 mm

200 mm

10D 100 mm 150 mm 200 mm 250 mm 320 mm

400 mm

WFK2

Series

Metering valve

Metering valve