Summary of Contents for PV2 Series

Page 1: ...INSTALLATION GUIDE M233A01 03 18A Canopies PV2...

Page 2: ...2 PV2 Installation Guide...

Page 33: ...9 FINAL FOUNDATIONS Concrete Hormig n Figure 30 Final foundations 33 Installation Guide PV2...

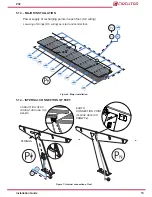

Page 34: ...10 INSTALLATION OF THE CHARGER Figure 31 Installation of the charger 34 PV2 Installation Guide...