OPERATING MANUAL

200HF

SERVICE 7-2 Manual 0-5406

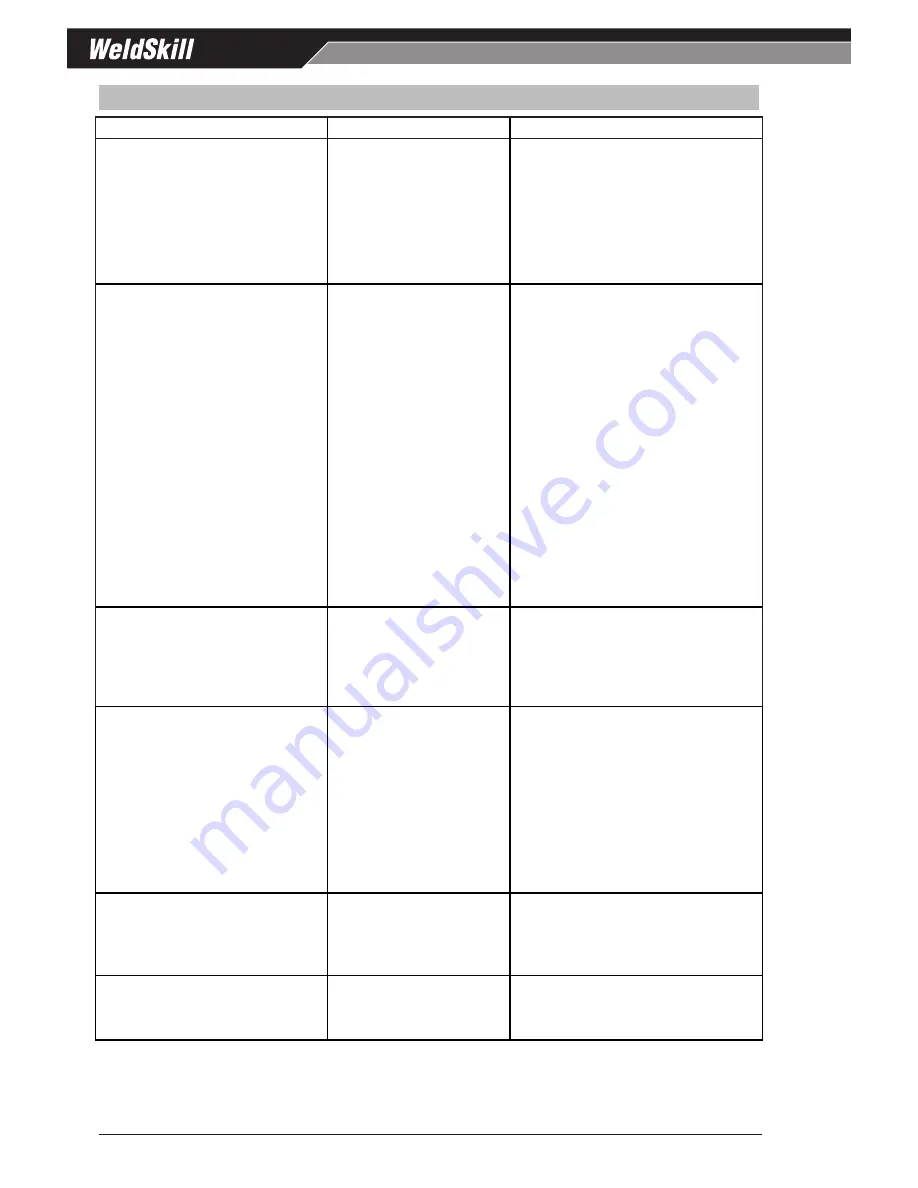

7.04 Power Source Problems

Description

Possible Cause

Remedy

1

Mains Supply Voltage is On,

the On/Off switch on the rear

panel is in the On position

and the Power indicator on

the front panel is illuminated

however the power source

will not STICK weld.

A

Power Source is not

in the correct mode

of operation.

A

Set the power source to STICK

mode.

B

Work Lead is not

connected to the

work piece.

B

Ensure that the Work Lead is

connected to the work piece and

has a good connection to the

work piece.

2

Mains Supply Voltage is On,

the On/Off switch on the rear

panel is in the On position

and the Power indicator on

the front panel is illuminated

however the power source

will not commence welding in

TIG modes.

A

Power Source is not

in the correct mode

of operation.

A

Set the power source to either

HF TIG or Lift TIG mode with the

process selection control. Refer

to section 4.02.4.

B

Work Lead is not

connected to the

work piece.

B

Ensure that the Work Lead is

connected to the work piece and

has a good connection to the

work piece.

C

TIG Torch 8 Pin

Control Plug not

connected correctly

or loose/faulty

connection in plug.

C

Connect 8 Pin TIG Torch control

plug securely and correctly to

the 8 Pin control socket of the

front of the WeldSkill 200HF

Power Source. Repair or replace

if faulty.

D

Faulty TIG Torch

Trigger.

D

Repair or replace TIG Torch

Trigger switch/lead.

3

Over Temp Indicator is

illuminated and unit will not

commence welding.

Duty cycle of power

source has been

exceeded.

Leave the power source switched

ON and allow it to cool. Note

that Over Temp indicator

must be extinguished prior to

commencement of welding.

4

The welding arc cannot be

established

A

The Mains supply

voltage has not been

switched ON

A

Switch ON the Mains supply

voltage

B

The Welding Power

Source switch is

switched OFF

B

Switch ON the Welding Power

Source

C

Loose connections

internally

C

Have an Accredited CIGWELD

Service Provider repair the

connection

5

Maximum output welding

current cannot be achieved

with nominal Mains supply

voltage

Defective control

circuit

Have an Accredited CIGWELD

Service Provider inspect then

repair the welder

6

Welding current reduces

when welding

Poor work lead

connection to the

work piece

Ensure that the work lead has a

positive electrical connection to

the work piece

Summary of Contents for WELDSKILL 200HF

Page 22: ...OPERATING MANUAL 200HF INSTALLATION 3 4 Manual 0 5406 This Page Intentionally Blank ...

Page 28: ...OPERATING MANUAL 200HF OPERATION 4 6 Manual 0 5406 This Page Intentionally Blank ...

Page 38: ...OPERATING MANUAL 200HF SERVICE 5 10 Manual 0 5406 This Page Intentionally Blank ...

Page 56: ...KEY SPARE PARTS 8 2 Manual 0 5406 OPERATING MANUAL 200HF This Page Intentionally Blank ...

Page 59: ...OPERATING MANUAL 200HF This Page Intentionally Blank ...