Maintenance

12

MV1864P

•Disconnect Power Prior To Maintaining Or Cleaning The Fan. The fan may start automatically causing serious

injury or death.

• Service and repair of fans should be done only by a qualified technician.

• Keep the Fan clean for maximum life and best performance.

Do Not spray water on Fan Shaft Bearings, Belt

Tensioner, or the Motor.

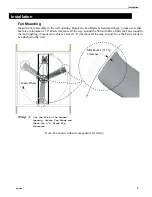

• Periodically check the V-Belt and replace if necessary. A bad Belt will cause a substantial drop in Fan perfor-

mance or can break and cause Fan failure. If a Belt rides below the Sheave edge, replace the Belt.

(See Figure 13)

• Keep HYFLO

®

Doors, Blades, and Housing clear of obstacles for best air performance.

•Check Sheaves for wear. Replace if Sheave

groove is worn.

(See Figure 13 to the Right).

Fan Bearing and Belt Tensioner

Lubrication

•

Grease zerks are provided for lubrication on the fan shaft bearings and the belt tensioner.

•

Lubricate the fan every 2-6 months or whenever these components get wet.

•

Disconnect power to the fan before lubricating.

•

Clean the zerk before lubricating to prevent contamination from entering the bearing.

•

Use a high quality lithium based, NLGI #2, grease such as Shell Gadus S2 V100 2. Do not use incompatible greases

containing aluminum, barium, calcium, bentonite clay or polyurea thickeners.

•

Slowly rotate the fan shaft by hand while slowly applying the grease. Rapidly applying grease to a stationary bearing

can damage the bearing seals.

•

Apply about .10 oz (2.8 g, 3.1 cc) of grease at a time or until a slight amount of grease can be seen purging from the

seal.

Maintenance

Worn Sheave

(Needs Replaced)

Good Belt

Bad Belt

Good Sheave

Bad Sheave

MV1700-020 04/02

Bad Belt

(Needs Replaced)

Figure 13. Worn Sheave

Grease Zerk

Grease Zerk