Model: MWC Series

Installation Instructions

6

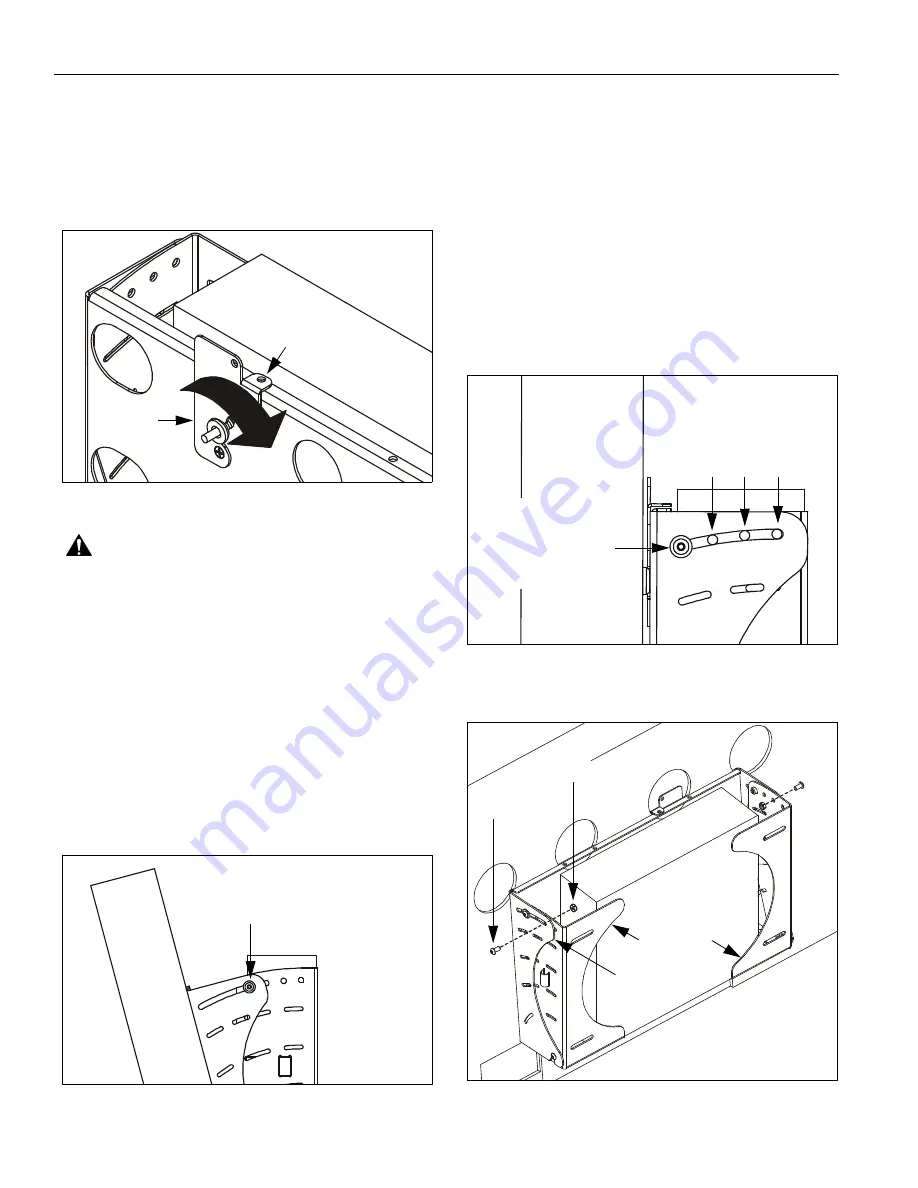

NOTE:

If Q-Latch does not fully close, ensure mounting

buttons are fully seated in the button openings.

NOTE:

A hole is provided in both the Q-Latch and the

front plate to accommodate the insertion of a

padlock or similar locking device.

Figure 9: Close Q-Latch

WARNING:

Make sure the latch securing the display

is fully closed at all times except when removing or

installing the display. The latch must be fully closed

when installing or removing cables from the display.

5.

Attach all cables to display and CPU.

TILT ADJUSTMENT

1.

If desired, the display may be tilted to any position

between 0° and 15°.

•

Slightly loosen upper front plate attach screws

(See Figure 10). Do NOT remove screws.

•

Tilt display to desired angle.

•

Tighten upper attach screws.

Figure 10: Tilt Adjustment

TILT LOCK

1.

If desired, the display may be locked at 0°, 5°, or 10°.

NOTE:

A positive stop exists at 15° without the use of an

additional locking screw.

•

Slightly loosen the upper front plate attach

screws. Do NOT remove screws.

•

Using key (60), loosely install screws (40) through

the slot in the front plate, through the applicable

open tilt lock hole in the side plate, into nut (50)

(See Figure 11)(See Figure 12).

•

Tilt display until lock is reached.

•

Tighten all four screws (upper front plate attach,

and 40).

Figure 11: Tilt Lock Holes

Figure 12: Tilt Lock Screw Installation

CLOSED

Locking device

installed here

Q-Latch

NOTE: Display and interface

not shown for clarity.

Upper front plate

attach screws

(2 places)

NOTE: Display

shown at 15°

position.

Upper front plate

attach screws

(Right side shown;

0°

5°

10°

Tilt lock holes

left side similar)

(Right side shown;

left side similar)

40 (2 places)

50 (2 places)

Side plate

Front plate